Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

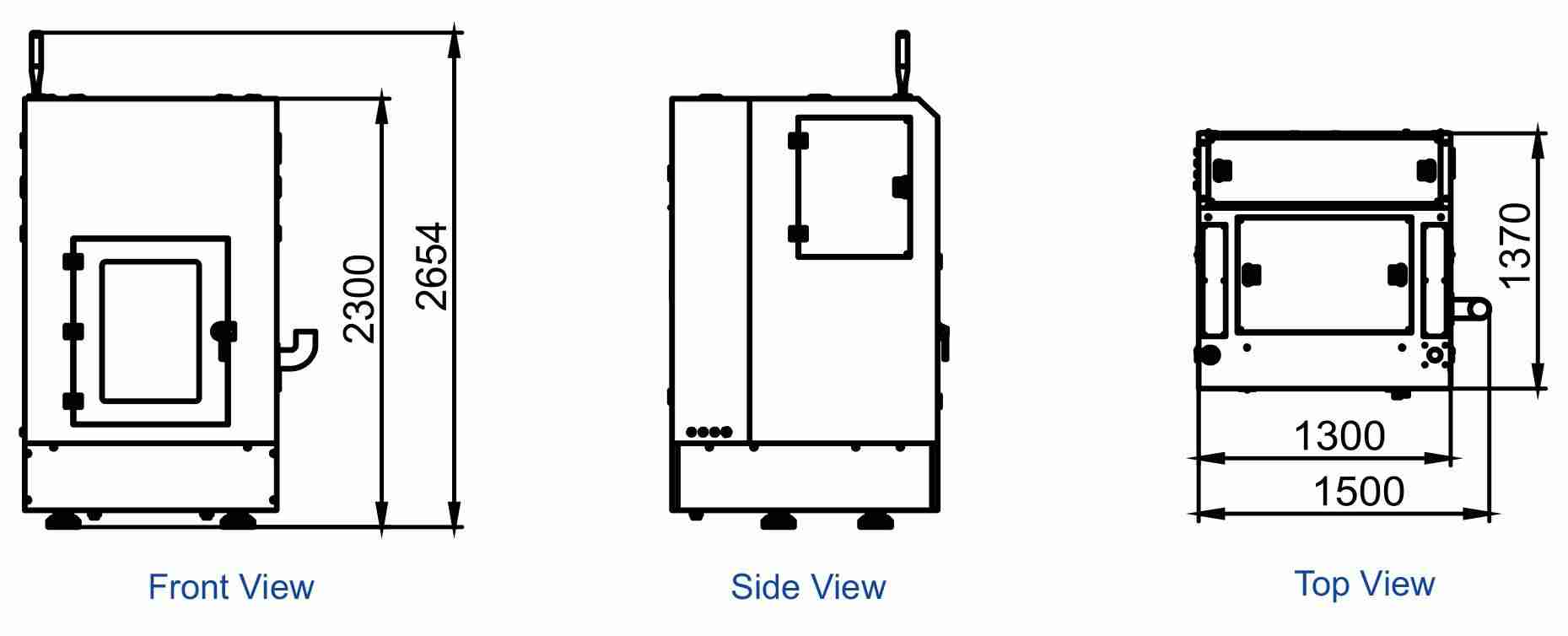

LightGRIND LT10 Single-laser Grinding Machine revolutionizes precision manufacturing with its advanced CNC system and self-developed CAM software. Featuring automatic loading, online defect detection, and a high-precision water-cooled turntable, it reduces processing time by 40% while achieving mirror finishes. This compact powerhouse delivers unparalleled accuracy and efficiency for automotive and 3C electronics industries.

Please fill in your contact information to download the PDF.