Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

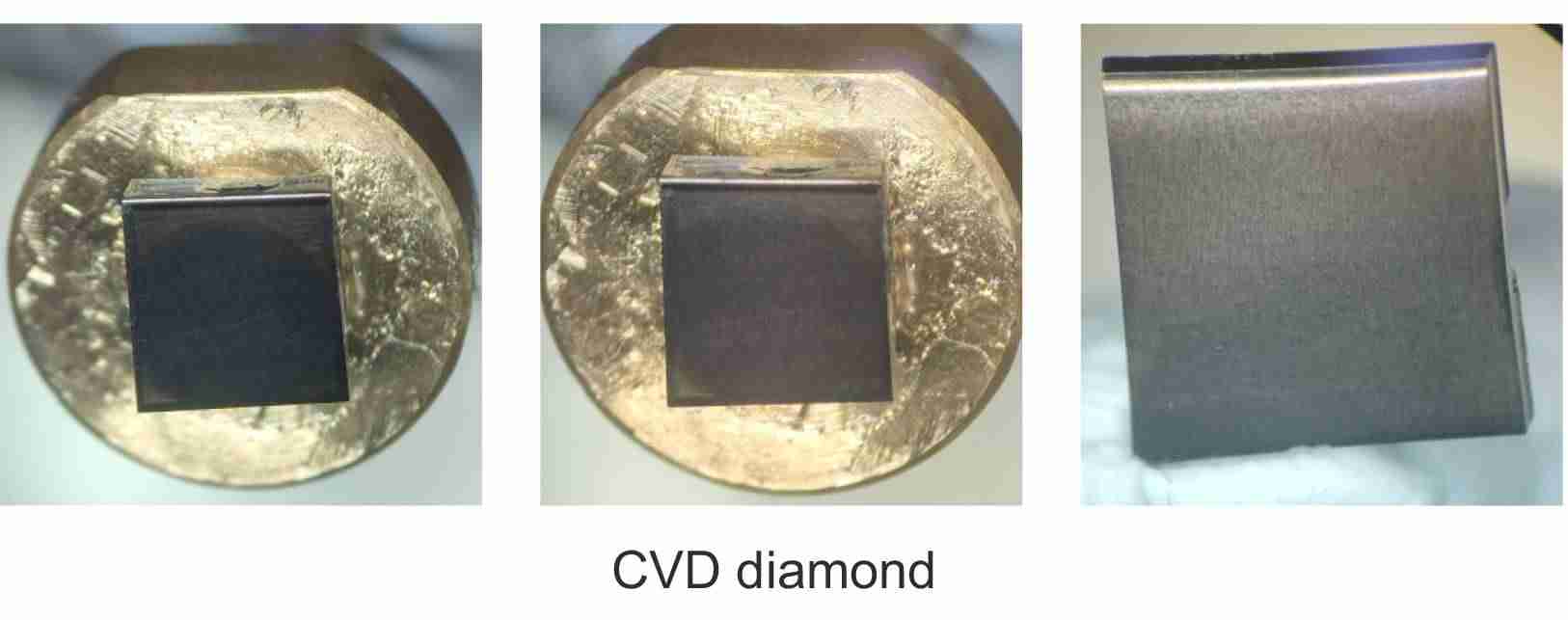

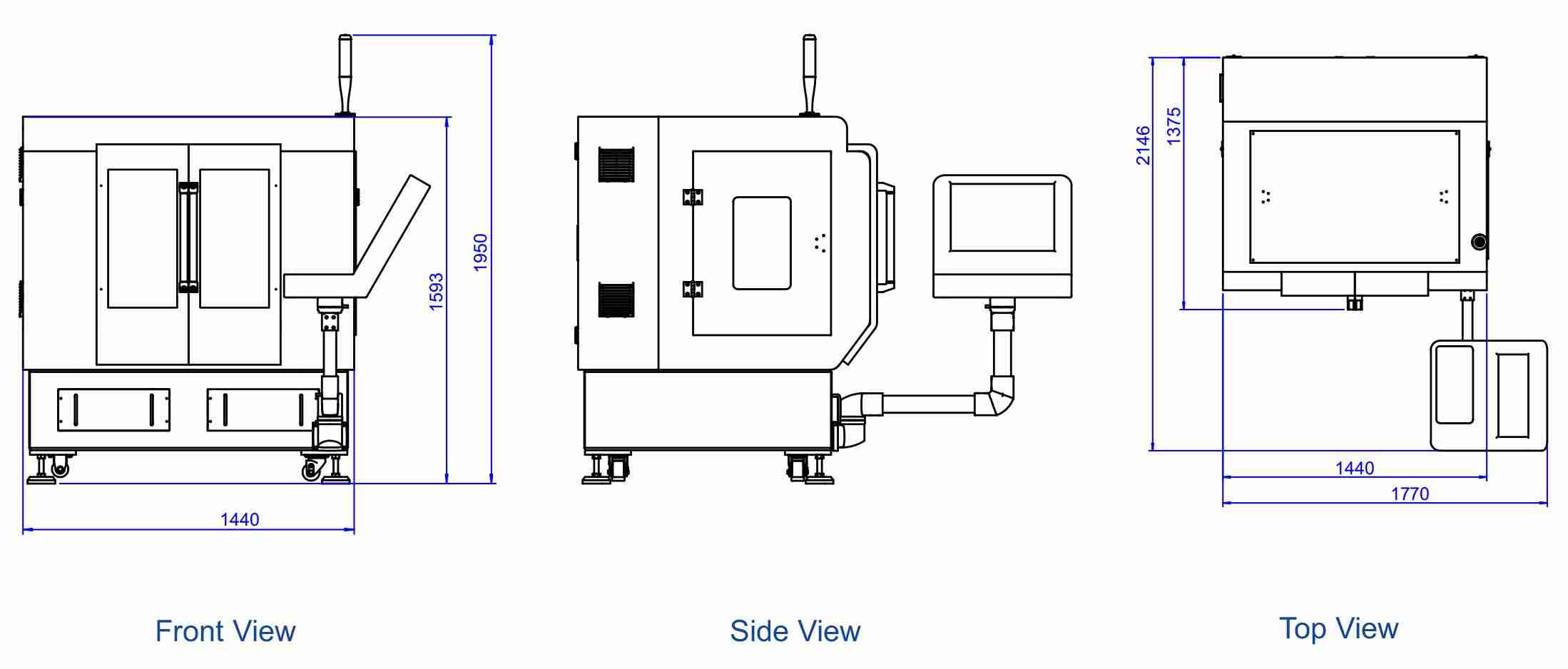

DiaCUT L315V CVD Laser Diamond Surface Grinding Machine revolutionizes precision manufacturing with its optimized design and high-definition visual calibration system. Featuring a 300% faster processing time and near-perfect yield rate, it offers unparalleled efficiency for automotive and 3C electronics industries. With 0.01mm positioning accuracy and flexible quadrilateral processing, the DiaCUT L315V delivers superior surface quality and versatility for demanding applications.

Please fill in your contact information to download the PDF.