Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

In today’s fast-paced manufacturing world, where efficiency, sustainability, and personalization reign supreme, laser texture processing has emerged as a game-changing innovation. This cutting-edge technology is reshaping the landscape of mold and product design, offering unparalleled advantages over traditional methods.

Surface modification has undergone significant advancements, transforming manufacturing processes across industries. This evolution has led to more precise, efficient, and environmentally friendly methods of altering material surfaces.

In the past, chemical etching was the primary method for texturing molds and other surfaces. This process involved:

The introduction of laser texture processing in recent years has addressed many limitations of chemical etching:

| Feature | Chemical Etching | Laser Texturing |

|---|---|---|

| Precision | Limited | Micrometer accuracy |

| Consistency | Variable | Highly uniform |

| Environmental Impact | High | Minimal |

| Design Flexibility | Restricted | Extensive |

| Processing Time | Long | Significantly reduced |

Laser texturing has revolutionized surface modification by:

Modern surface texturing techniques find applications in various industries:

These advancements have led to:

As of 2025, ongoing research continues to refine laser texturing techniques, promising even greater precision and versatility in surface modification.

Laser texture processing is transforming surface engineering by enabling precise, efficient, and eco-friendly material modification. This cutting-edge technique harnesses focused light beams to etch intricate patterns directly onto material surfaces, offering unparalleled control and versatility.

How does laser texture processing achieve such remarkable results? By utilizing high-powered lasers, manufacturers can create complex textures with micrometer-level accuracy. This process dramatically reduces production cycles compared to traditional methods. The laser’s precision allows for:

Why is laser texturing considered environmentally friendly? Unlike conventional texturing methods, laser processing eliminates the need for harsh chemicals. This approach:

How does laser texturing empower designers? The technology’s versatility allows for:

Designers can now push the boundaries of product aesthetics and functionality, exploring new possibilities in surface engineering.

What functional benefits does laser texturing offer? Beyond visual appeal, laser-textured surfaces can enhance product performance:

| Functional Benefit | Application Example |

|---|---|

| Anti-slip properties | Improved grip on tools |

| Fingerprint resistance | Sleek electronic device finishes |

| Glare reduction | Enhanced display visibility |

These improvements contribute to both product usability and consumer satisfaction.

Where is laser texture processing making an impact? Its versatility has led to adoption in various sectors:

What’s next for laser texture processing? As the technology continues to evolve, we can expect:

Laser texture processing is poised to play a crucial role in advancing surface engineering techniques, driving innovation across multiple sectors.

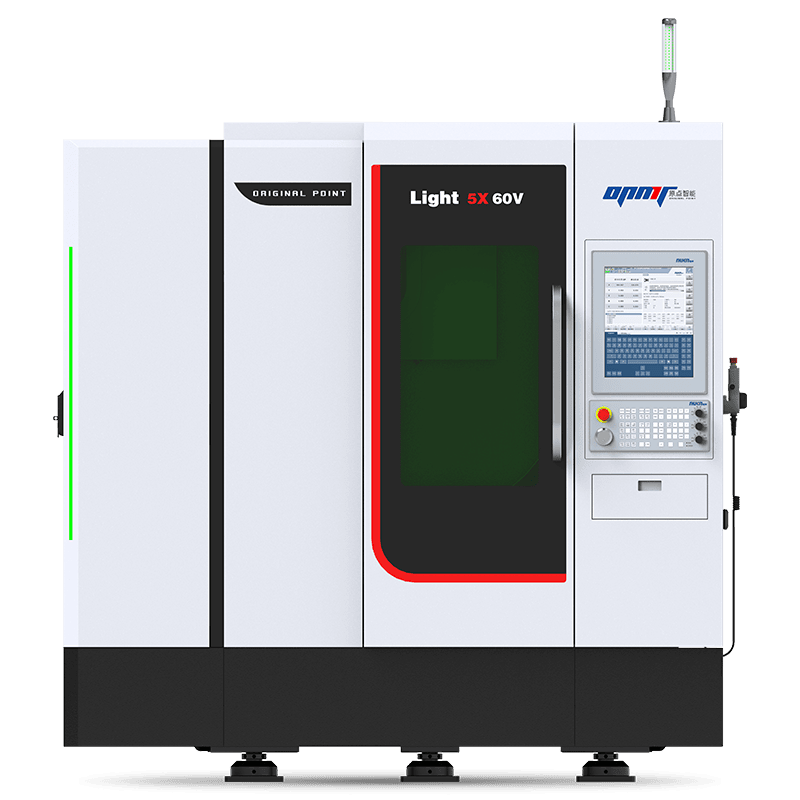

Light 5X 60V Vertical 5-Axis Laser Machining Center

– Tool Carving

OPMT’s advanced 5-axis laser texture processing solution is revolutionizing the manufacturing landscape by delivering exceptional precision and efficiency. This innovative system enables manufacturers to create intricate surface textures and functional patterns across a diverse range of materials, including metals, ceramics, and plastics. With its ability to perform complex 3D surface texturing, OPMT’s technology meets the growing demand for high-quality, customized products in various industries.

The 5-axis laser texturing technology offers several compelling benefits:

OPMT’s system integrates cutting-edge features that enhance its performance:

As industries increasingly prioritize customization and quality, OPMT’s laser texture processing technology is set to play a pivotal role in shaping the future of manufacturing. By leveraging this advanced solution, manufacturers can elevate their product offerings to new levels of sophistication and functionality. With ongoing innovations in laser technology, OPMT remains committed to providing cutting-edge solutions that meet the evolving needs of the market.

Laser texture processing represents a significant leap forward in manufacturing technology. Its ability to combine precision, efficiency, and design freedom is transforming how we approach surface texturing across multiple industries. As companies like OPMT continue to push the boundaries of what’s possible with laser technology, we can expect to see even more innovative applications and advancements in the years to come.

For manufacturers looking to stay ahead of the curve and deliver products that stand out in today’s competitive market, embracing laser texture processing is not just an option – it’s a strategic imperative.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.