Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

In the ever-evolving landscape of advanced manufacturing, laser technology has emerged as a game-changer for processing superhard materials. This cutting-edge approach is reshaping industries by offering unparalleled precision, efficiency, and versatility. Let’s delve into the transformative power of laser processing and its far-reaching implications for the future of manufacturing.

Laser processing has become the go-to solution for tackling superhard materials, outperforming traditional methods in several key areas:

Unmatched Efficiency: Laser beams concentrate immense energy onto materials, enabling rapid heating and processing. This dramatically reduces production cycles, boosting overall manufacturing productivity.

Micron-Level Precision: The stability and accurate positioning of laser beams allow for incredibly precise processing, minimizing material deformation and ensuring consistent quality.

Eco-Friendly Operations: Unlike conventional methods, laser processing eliminates the need for cutting fluids or coolants, reducing environmental impact and energy consumption.

Versatility in Application: Laser technology adapts to various shapes and sizes of superhard materials, seamlessly integrating with advanced manufacturing systems like CNC machine tools to expand processing capabilities.

As the demand for processing superhard materials grows, companies and research institutions worldwide are developing groundbreaking solutions:

OPMT Intelligence’s Light 5X Series: These laser CNC machine tools excel in high-precision positioning, enabling efficient processing of complex contours.

LightGRIND Series: This innovative line offers machines for surface grinding, contour processing, and special-shaped contour processing. The laser grinding efficiency surpasses traditional grinders by more than tenfold, achieving remarkable precision:

Laser technology has revolutionized the manufacturing of Polycrystalline Diamond (PCD) tools:

Compared to conventional methods, laser grinding of diamond offers:

In the realm of micro-hole processing, laser technology stands out for diamond composite materials:

As technology advances and application demands increase, the future of laser processing for superhard materials looks promising:

Expect more powerful lasers with improved beam quality, enabling faster and more precise processing.

In the era of Industry 4.0, laser processing equipment will become more intelligent and automated, with real-time monitoring and adjustment capabilities.

As superhard materials find new uses across industries, laser processing is poised to become the primary manufacturing method in aerospace, automotive, and energy sectors.

The impact of laser technology on superhard material processing is undeniable. Its ability to deliver precision, efficiency, and versatility is transforming manufacturing processes across industries. As we look to the future, continuous innovation in laser technology promises to unlock even greater potential, pushing the boundaries of what’s possible in advanced manufacturing.

For manufacturers and engineers alike, staying abreast of these developments is crucial. The laser revolution is not just reshaping how we process superhard materials—it’s redefining the very limits of manufacturing precision and efficiency.

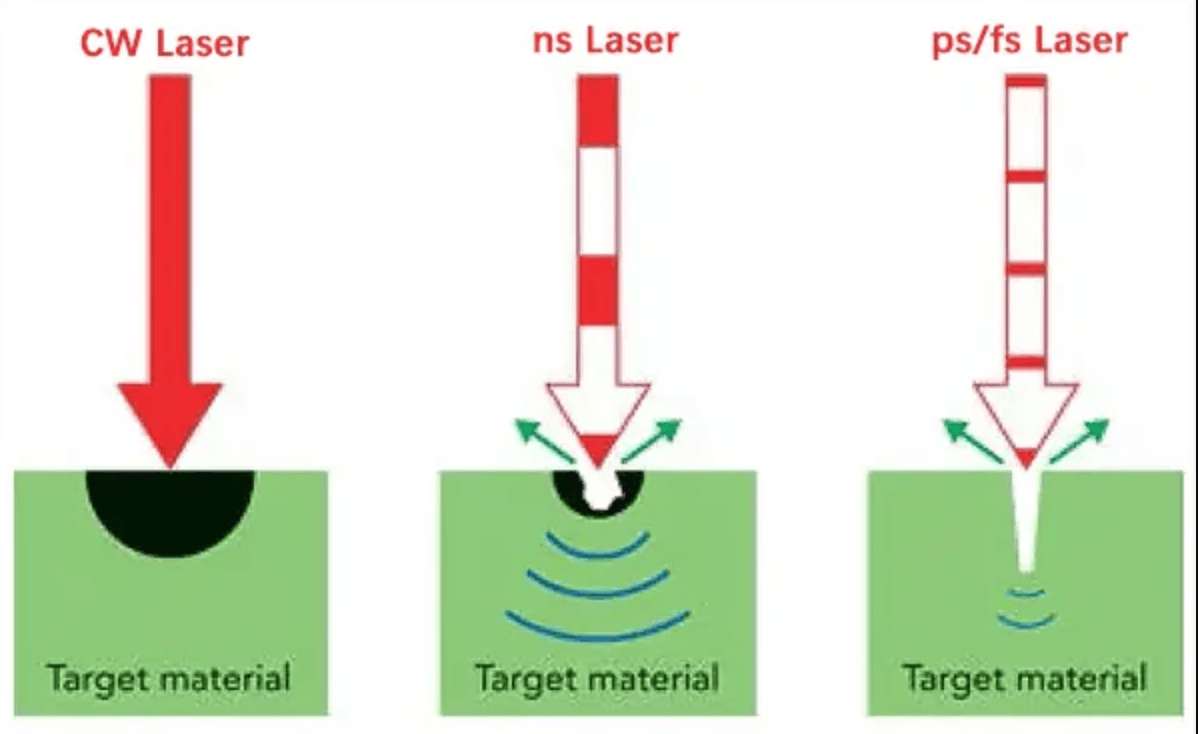

Compare picosecond vs nanosecond laser systems for industrial manufacturing. HAZ data, processing speeds, cost analysis, and application criteria from OPMT’s deployed systems.

PCD laser cutting machines deliver 0.003mm accuracy and 3x faster processing than EDM. Complete technical guide to polycrystalline diamond tool manufacturing for aerospace and automotive industries.

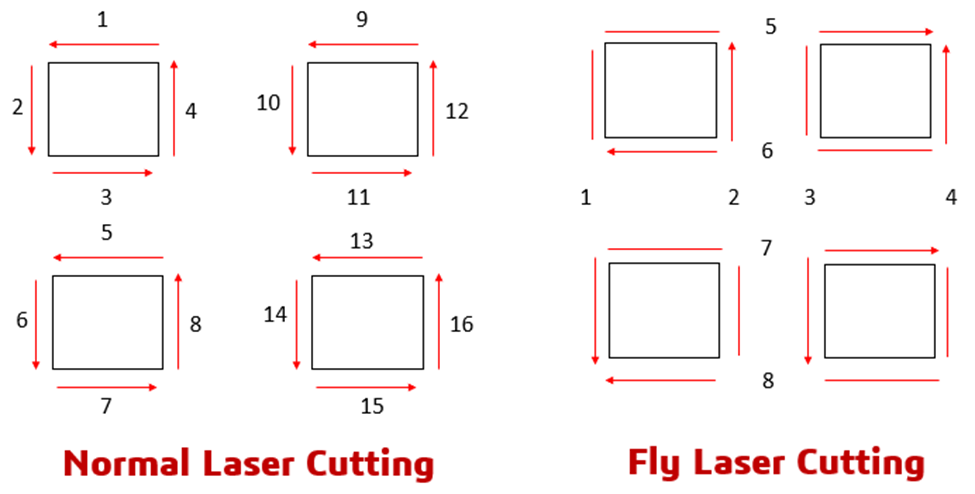

Fly cut laser technology reduces cycle time by 30-50% through continuous motion path optimization. Learn mechanics, applications, and OPMT equipment specifications for precision manufacturing.

Factory evaluation frameworks for laser cutting equipment procurement. Infrastructure assessment, quality systems analysis, and total cost of ownership calculations based on 30+ facility audits.

Please fill in your contact information to download the PDF.