Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

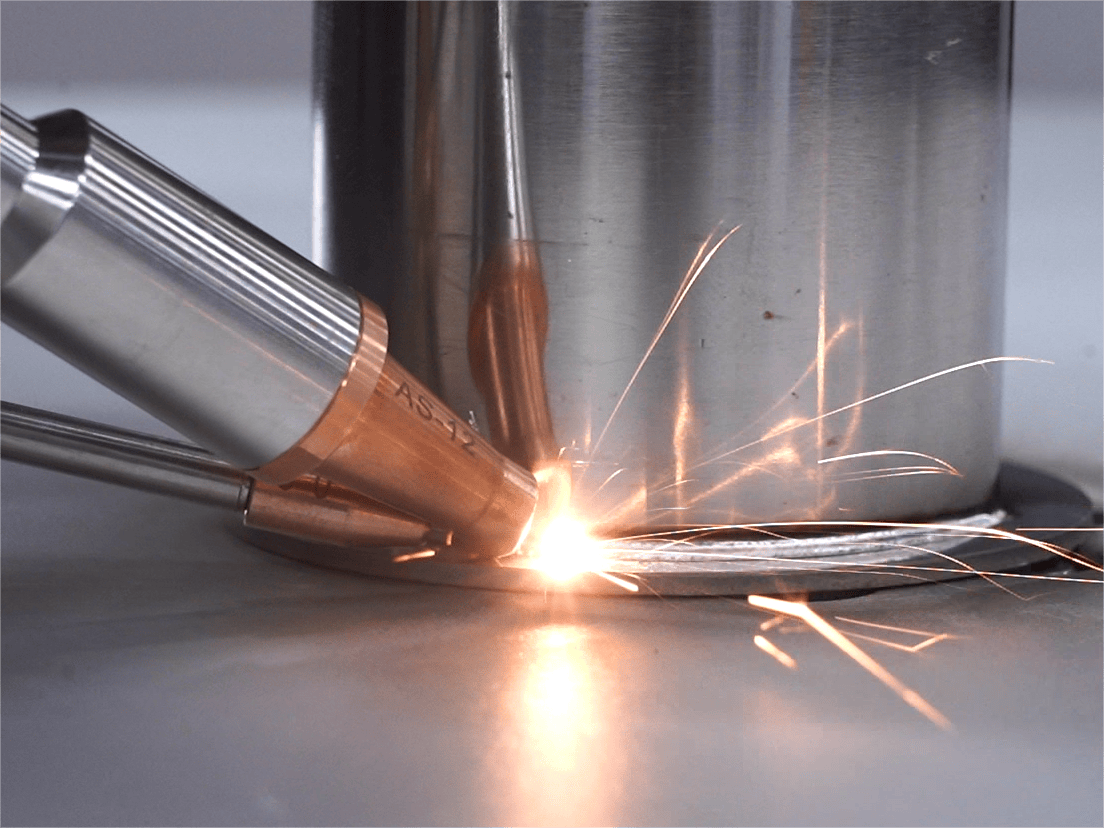

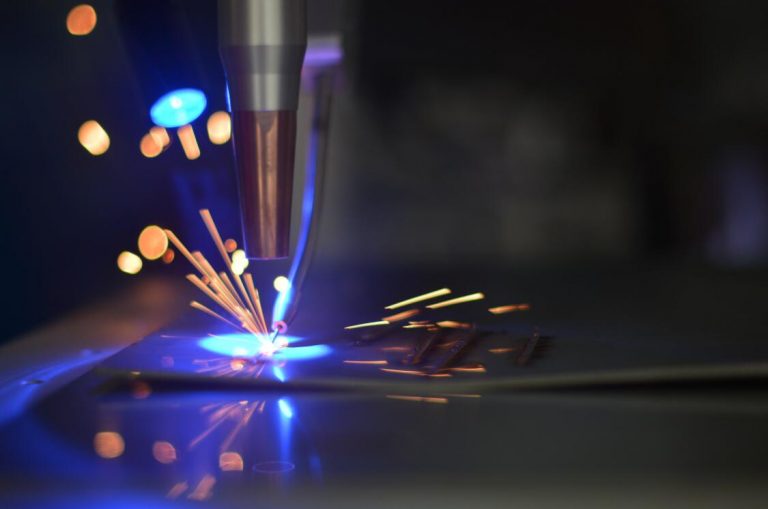

Handheld laser welding technology represents a significant advancement in the welding industry, offering numerous benefits over traditional methods. This innovative approach utilizes a high-powered laser beam to fuse materials quickly and efficiently, resulting in clean, aesthetically pleasing welds with minimal heat distortion.

Key advantages of handheld laser welders include:

Overall, handheld laser welding is transforming manufacturing processes by delivering high-quality results while minimizing costs and operational complexities.

A handheld laser welding machine is a portable device that utilizes advanced laser technology for non-contact welding. This innovative tool enables users to instantly melt various metals using a concentrated laser beam, which cools rapidly to form strong welds without mechanical pressure. Its portability and versatility make it suitable for a wide range of applications across multiple industries, including automotive, aerospace, and metal fabrication.

Handheld laser welding machines operate on the principle of localized heating through high-energy laser pulses. This method offers several advantages over traditional welding techniques:

A handheld laser welding machine consists of several essential components:

Handheld laser welding machines have revolutionized the welding industry by providing numerous advantages over traditional welding methods. These benefits enhance productivity, quality, and operational efficiency across various sectors.

Precision and Quality

Efficiency and Speed

Flexibility and Portability

Environmental Considerations

Handheld laser welding machines offer remarkable precision, efficiency, and versatility while minimizing operational costs and environmental impact. Their growing popularity across various industries highlights their importance as an advanced solution for modern welding challenges.

Handheld laser welding technology has become a crucial advancement across various industries, delivering exceptional speed, precision, and quality in welding processes. This innovative method is particularly beneficial in sectors where high-quality welds are essential for maintaining product integrity and performance. Below are the key industries that are leveraging handheld laser welding technology.

Efficient Component Joining:

Handheld laser welding is widely utilized for joining critical automotive components such as chassis, body panels, and exhaust systems. The precision of this technology ensures robust connections that can endure the demanding conditions of automotive applications.

Boosting Production Speed:

The rapid nature of handheld laser welding significantly reduces production time, which is vital in the competitive automotive sector where quick time-to-market is essential. This efficiency enables manufacturers to meet high demand while upholding quality standards.

Safe Assembly of Delicate Components:

In electronics manufacturing, handheld laser welding is ideal for assembling sensitive components like microchips and circuit boards. The technology minimizes heat input, thereby reducing the risk of damage to delicate parts during the welding process.

Ensuring Quality Control Standards:

The high-quality welds produced by handheld laser machines comply with stringent industry standards, guaranteeing the reliability and functionality of electronic devices.

Creating Strong Seals:

Handheld laser welding plays a vital role in forming durable seals on stainless steel parts used in medical devices. This capability is crucial for maintaining both sterility and durability in medical applications.

Regulatory Compliance:

The precision offered by this technology aligns with strict regulatory standards in medical device manufacturing, thereby enhancing overall product safety and efficacy.

Durable Aesthetic Products:

This technology is commonly employed in crafting stainless steel kitchenware and furniture items. Handheld laser welding not only ensures strong welds but also provides aesthetically pleasing finishes that meet consumer demands for both functionality and design.

Versatile Design Applications:

The adaptability of handheld laser welding allows it to accommodate various designs, making it suitable for both functional kitchen items and decorative furniture pieces.

Precision Welding of Lightweight Materials:

In aerospace manufacturing, handheld laser welding is used to join lightweight materials such as aluminum and titanium alloys. This technology delivers the precision needed to create complex components while minimizing weight, which is critical for aircraft performance.

Handheld laser welding technology also finds applications in:

Handheld laser welding technology is revolutionizing production processes across these industries by improving efficiency, enhancing product quality, and enabling innovative design possibilities. Its ability to deliver precise, clean welds with minimal heat distortion makes it an invaluable tool in modern manufacturing practices.

As manufacturing technologies progress, selecting between handheld laser welding and conventional welding methods becomes crucial. Each technique offers distinct advantages and disadvantages that impact efficiency, precision, and application suitability.

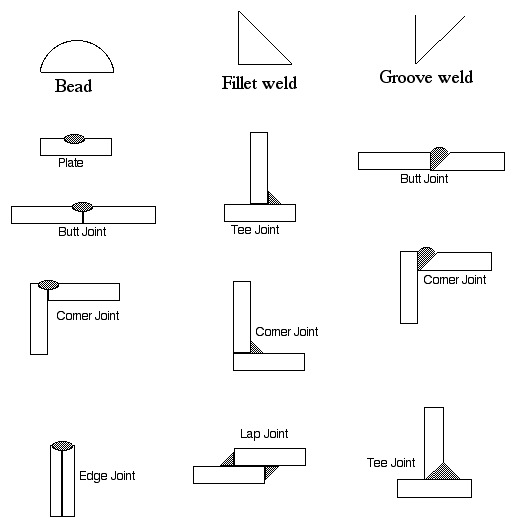

Conventional Welding encompasses various techniques, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding. This method utilizes an electric arc or gas flame to melt and join materials. However, it typically involves high heat input, which can lead to significant thermal distortion and a larger heat-affected zone (HAZ), potentially compromising the integrity of the welded materials.

In contrast, handheld laser welding employs a focused laser beam to create welds with minimal heat input. This process allows for precise control, resulting in clean and robust welds. The small HAZ generated during this method reduces the risk of warping or deformation in thin materials.

| Feature | Handheld Laser Welding Machine | Conventional Welding |

|---|---|---|

| Heat Input | Low, focused heat minimizes damage | High heat can weaken surrounding areas |

| Precision | Extremely high precision for intricate designs | Depends on the welder’s skill |

| Thermal Distortion | Minimal due to rapid cooling | More prone to warping |

| Material Compatibility | Works with thin and exotic metals | Generally suited for thicker metals |

| Speed | Faster processes | Slower; requires setup |

| Versatility | Handles complex shapes easily | Effective for general tasks |

| Post-Weld Cleanup | Often requires no cleanup | Usually requires grinding |

Handheld laser welding offers numerous advantages over conventional methods, particularly regarding precision, speed, and reduced thermal distortion. However, the higher initial costs and maintenance requirements may pose challenges for some users. The choice between these methods should be guided by specific project needs, material types, and budget considerations. For applications requiring high accuracy and minimal distortion—such as in aerospace or medical device manufacturing—handheld laser welding is often the superior choice. Conversely, traditional methods may still hold value in larger-scale operations where cost-effectiveness is essential.

Handheld laser welding technology marks a transformative shift in the welding industry, providing substantial advantages over traditional methods. This innovative approach not only enhances speed and efficiency—operating up to four times faster than conventional techniques—but also ensures exceptional precision and control, making it ideal for intricate applications across various sectors.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

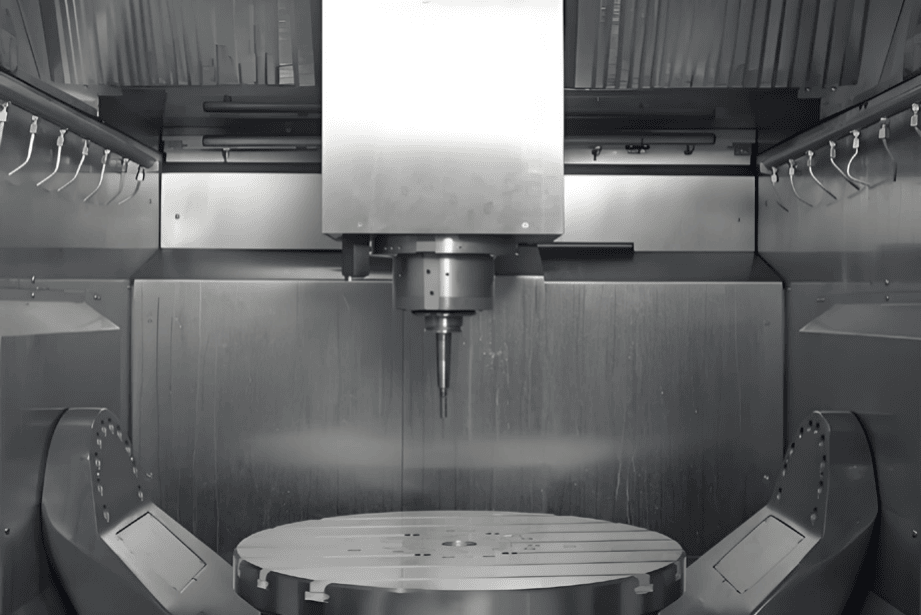

Discover how advanced vertical 5-axis CNC systems achieve ±0.001-0.005mm micron-level precision for aerospace, medical, and automotive applications in 2026.

Comprehensive guide to 5-axis laser cutting machines: technology principles, advantages over 3-axis systems, industrial applications, and specifications for precision manufacturing.

Discover how 5-axis laser engraving machines deliver micron-level precision for complex surface marking, mold texturing, and industrial component identification across aerospace, automotive, and medical sectors.

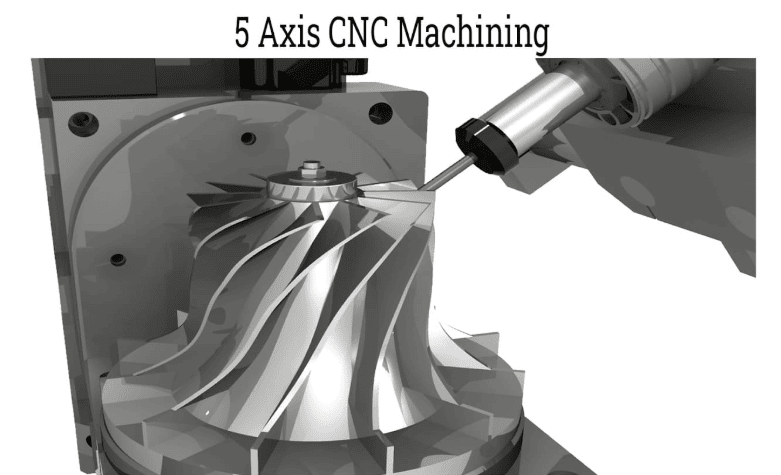

Discover 5-axis machining operations including simultaneous, indexed positioning, and configuration types. Learn cutting methods for aerospace, medical & automotive applications.

Please fill in your contact information to download the PDF.