Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

In today’s competitive manufacturing landscape, the integration of automation in CNC laser welding represents a transformative approach to boosting productivity, precision, and operational efficiency. This comprehensive guide explores how automated material handling systems are revolutionizing laser welding operations, providing manufacturers with the insights needed to implement these technologies effectively.

The evolution of laser welding technology has fundamentally changed manufacturing processes across industries. Automation has become the cornerstone of this transformation, elevating the capabilities of laser welding systems to unprecedented levels.

Automation in laser welding delivers multiple advantages that traditional manual processes cannot match. The precision of a finely focused laser beam allows for exact control over the welding area, ensuring only targeted material is affected, which significantly reduces the heat-affected zone and minimizes distortion. With automated systems, manufacturers achieve consistent, high-quality welds with repeatability that human operators simply cannot match.

The speed enhancement is equally impressive. What once took 90 minutes with manual gas-tungsten-arc welding (GTAW) can now be completed in just 10 minutes using automated laser welding systems. This dramatic reduction in cycle time translates directly to increased throughput and improved productivity.

Beyond speed and precision, automated laser welding systems offer:

The transition from traditional CO2 lasers to advanced fiber lasers has been instrumental in enhancing automation capabilities. Fiber lasers provide more stable and consistent output, which is essential for maintaining high-quality welds. They’re faster, more precise, and require less maintenance, making them ideal for automated welding processes.

Implementing the right material handling solution is crucial for maximizing the efficiency of CNC laser welding operations. Several options exist, each with distinct advantages for specific applications.

Robots represent the cornerstone of modern automated material handling in laser welding. They perform tasks with exceptional precision and repeatability, significantly enhancing production efficiency. The most common robotic systems include:

Robotic systems excel at maintaining consistent weld quality by positioning laser heads with exceptional accuracy and following programmed paths precisely. They’re particularly valuable in high-volume production environments where thousands of welds must be performed with consistent quality.

Automated conveyor systems ensure smooth part flow through the welding process. These systems can include:

These systems optimize workflow by minimizing downtime between operations and maintaining a steady production pace.

For manufacturers looking to streamline implementation, ready-to-integrate laser welding packages offer significant advantages. These comprehensive solutions typically include:

These packages significantly reduce setup time and development costs associated with custom configurations. They feature advanced monitoring capabilities through machine vision and real-time process monitoring, ensuring precise laser beam alignment and detecting anomalies during welding.

Comparison of Automated Handling Systems

| System Type | Best Applications | Advantages | Limitations |

|---|---|---|---|

| 6-Axis Robots | Complex 3D welds, varied part geometries | Maximum flexibility, large work envelope, high precision | Higher initial cost, more complex programming |

| SCARA Robots | Repetitive tasks, planar applications | Fast cycle times, good precision, lower cost | Limited to simpler movements, smaller work area |

| Cobots | Small batch production, human-collaborative environments | Easy programming, flexible deployment, safety features | Lower payload capacity, slower operation speeds |

| Conveyor Systems | High-volume production, linear part flow | Continuous operation, consistent timing, scalable | Less flexible for varied part types, fixed pathways |

| Ready-to-Integrate | New adopters, standardized applications | Faster implementation, reduced integration complexity | May require adaptations for unique requirements |

Successfully implementing robotic systems for material handling in laser welding requires careful planning and consideration of several key factors.

When integrating robots with CNC laser welding equipment, consider these proven approaches:

Proper integration requires attention to both hardware and software aspects. Manufacturers should prioritize systems with user-friendly interfaces that enable easy programming and adjustment of welding parameters through touch screen controls.

Despite the benefits, implementing robotic material handling systems presents several challenges:

Before implementing automated material handling for laser welding, manufacturers should assess:

Real-world implementations demonstrate the tangible benefits of automated material handling in laser welding operations.

A leading automotive supplier successfully integrated a robot-assisted laser welding system for seat back components. The system included:

This integrated system produces 148 welds in just 45 seconds, with comprehensive weld inspection ensuring each weld meets stringent quality standards. The system maintains tight part alignment, allows for quick changeovers, and provides flexibility to run different models and assemblies.

OPMT Laser collaborated with an electric vehicle industry customer to create an automated laser welding system for joining copper busbars to battery tabs. The six-axis robotic system ensures consistent and repeatable welds, improving safety with a Class 1 laser designation and enhancing efficiency through a customized Human-Machine Interface (HMI).

The system supports production of multiple part numbers in a single cycle and includes remote troubleshooting capabilities. This integration significantly improved consistency, repeatability, and efficiency in the welding process.

QTR, a machining and fabrication company, previously performed manual gas-tungsten-arc welding (GTAW) at a rate of 90 minutes per component. After implementing cobot laser welding, they reduced cycle time to just 10 minutes per component—an 89% reduction. Beyond the dramatic time savings, the company eliminated other problems such as distortion previously encountered with the GTAW process and no longer needed to clean parts after welding.

In the assembly of electric motors, ensuring the integrity and quality of welded hairpins is critical. A manufacturer implemented Senswork’s ZScan 360, an advanced 3D inspection system leveraging artificial intelligence (AI) to monitor the laser welding process for stators.

The system captures high-resolution data of welding spots and uses deep learning algorithms to evaluate weld quality in real-time. This implementation increased precision and safety in the welding process, improved efficiency through automation of the inspection process, and generated significant cost savings by minimizing defects and rework needs.

The future of automated material handling in CNC laser welding lies in the integration of artificial intelligence and Internet of Things technologies, which promise to further revolutionize manufacturing processes.

Artificial intelligence is revolutionizing material handling automation by optimizing workflows and predicting maintenance needs. AI implementations in laser welding include:

These AI systems continuously learn from operational data, constantly improving their performance and adapting to changing conditions. As one industry source notes, “AI injects a new level of intelligence and adaptability into manufacturing,” fundamentally transforming how tasks are executed in welding shops.

IoT technologies are transforming material handling in laser welding through comprehensive monitoring and system optimization. IoT applications include:

Through IoT, machine operators can observe cutting and welding parameters in real-time, receiving timely warnings if issues arise. This capability allows for necessary adjustments to maintain quality while improving workplace safety by reducing the need for operators to be physically present during operations.

Advanced data analysis enables predictive maintenance approaches that minimize downtime and extend equipment life:

These capabilities ensure that maintenance occurs based on actual equipment condition rather than fixed schedules, significantly reducing unplanned downtime while extending component lifespans.

Several emerging technologies promise to further transform automated material handling in laser welding:

As these technologies mature, they will enable even greater levels of precision, efficiency, and flexibility in CNC laser welding operations.

Automated material handling has fundamentally transformed CNC laser welding, delivering unprecedented levels of precision, efficiency, and consistency. From robotic systems that ensure repeatable quality to AI and IoT technologies that optimize operations in real-time, these innovations are reshaping manufacturing processes across industries.

As manufacturers navigate the implementation of these technologies, understanding the available options, best practices, potential challenges, and future trends becomes essential for success. By carefully selecting the right automated material handling solutions and following proven integration strategies, companies can achieve substantial productivity gains while maintaining the highest quality standards.

In a manufacturing landscape that demands ever-greater efficiency and precision, automated material handling in CNC laser welding stands as a critical competitive advantage. Companies that embrace these technologies position themselves at the forefront of innovation, ready to meet the challenges of today’s production environment while preparing for the opportunities of tomorrow.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

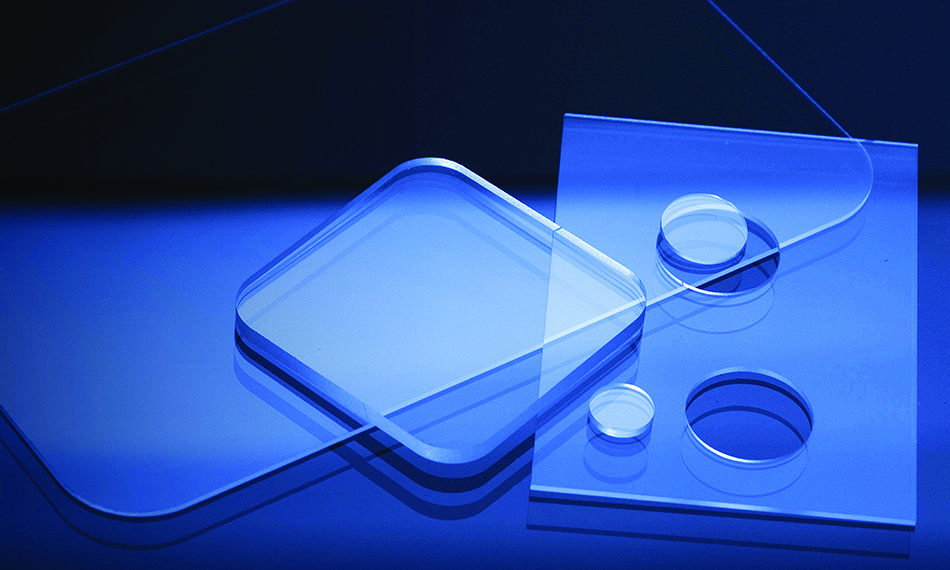

CO2 lasers cannot cleanly cut glass due to thermal stress. Discover why glass cracks and explore UV & femtosecond laser solutions for precision cutting.

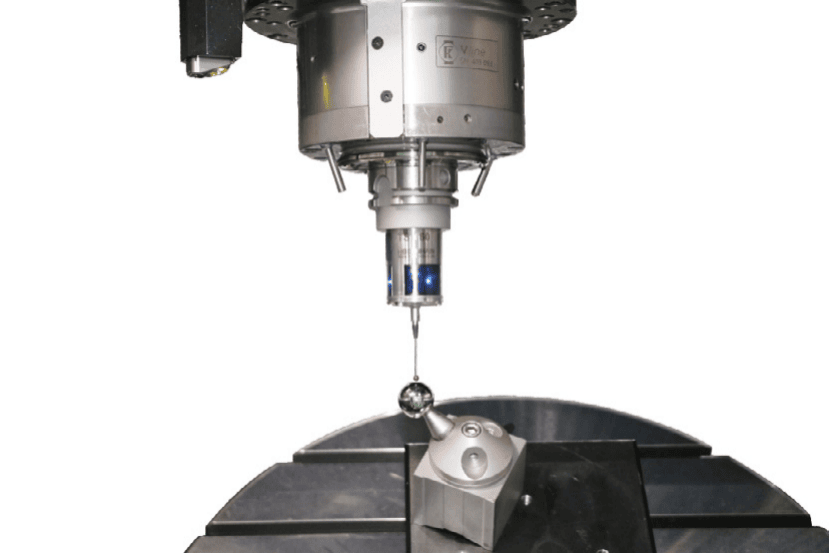

Compare femtosecond and nanosecond laser micromachining for 5-axis manufacturing. Learn how ISO 9001- and FDA-ready OPMT systems control HAZ, tolerances and surface integrity in medical, semiconductor and diamond applications.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Please fill in your contact information to download the PDF.