Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Chemical Vapor Deposition (CVD) has revolutionized diamond manufacturing, enabling the production of high-quality synthetic diamonds with precisely controlled properties for industrial applications. Unlike natural diamonds formed over millions of years under extreme geological conditions, CVD diamonds are created in controlled laboratory environments through sophisticated reactor systems. These synthetic diamonds exhibit exceptional mechanical, thermal, and optical properties that make them valuable across numerous high-tech industries.

OPMT Laser has established itself as a leader in the field of advanced laser processing solutions for lab-grown diamonds, offering specialized equipment designed to address the unique challenges associated with processing these superhard materials. With ISO 9001:2015 certification and multiple innovation awards in laser technology, OPMT delivers precision machining systems that transform raw CVD diamond into components with exceptional dimensional accuracy and surface quality.

The CVD diamond synthesis process involves carefully controlled deposition of carbon atoms onto a substrate under specific temperature, pressure, and gas composition conditions. This process creates diamond materials with various crystalline structures:

Once produced, these materials require sophisticated processing techniques to transform them into usable components with precise geometries and surface characteristics required for industrial applications.

Traditional diamond processing methods face significant challenges:

| Processing Method | Limitations with CVD Diamond |

|---|---|

| EDM (Electrical Discharge Machining) | – Chips and cracks at cutting edges – Cannot process non-conductive materials – Slow processing speed (1 mm/min) |

| Mechanical Grinding | – Rapid tool wear – Limited precision – Difficulty with complex geometries |

| Chemical Etching | – Poor dimensional control – Environmental concerns – Limited material removal rate |

As noted in OPMT’s technical comparison: “When processing large particles or polycrystalline diamond with poor conductivity, wire skipping will occur and machining cannot be continued” with traditional EDM methods, highlighting the need for advanced laser processing solutions.

The DiaCUT L315V CVD Laser Diamond Surface Grinding Machine represents OPMT’s dedicated solution for high-precision diamond surface processing. This system features:

Technical Specifications:

This specialized machine is specifically engineered for diamond applications, featuring precision line parallelism accuracy detection and laser interferometer calibration capabilities essential for high-end diamond component production.

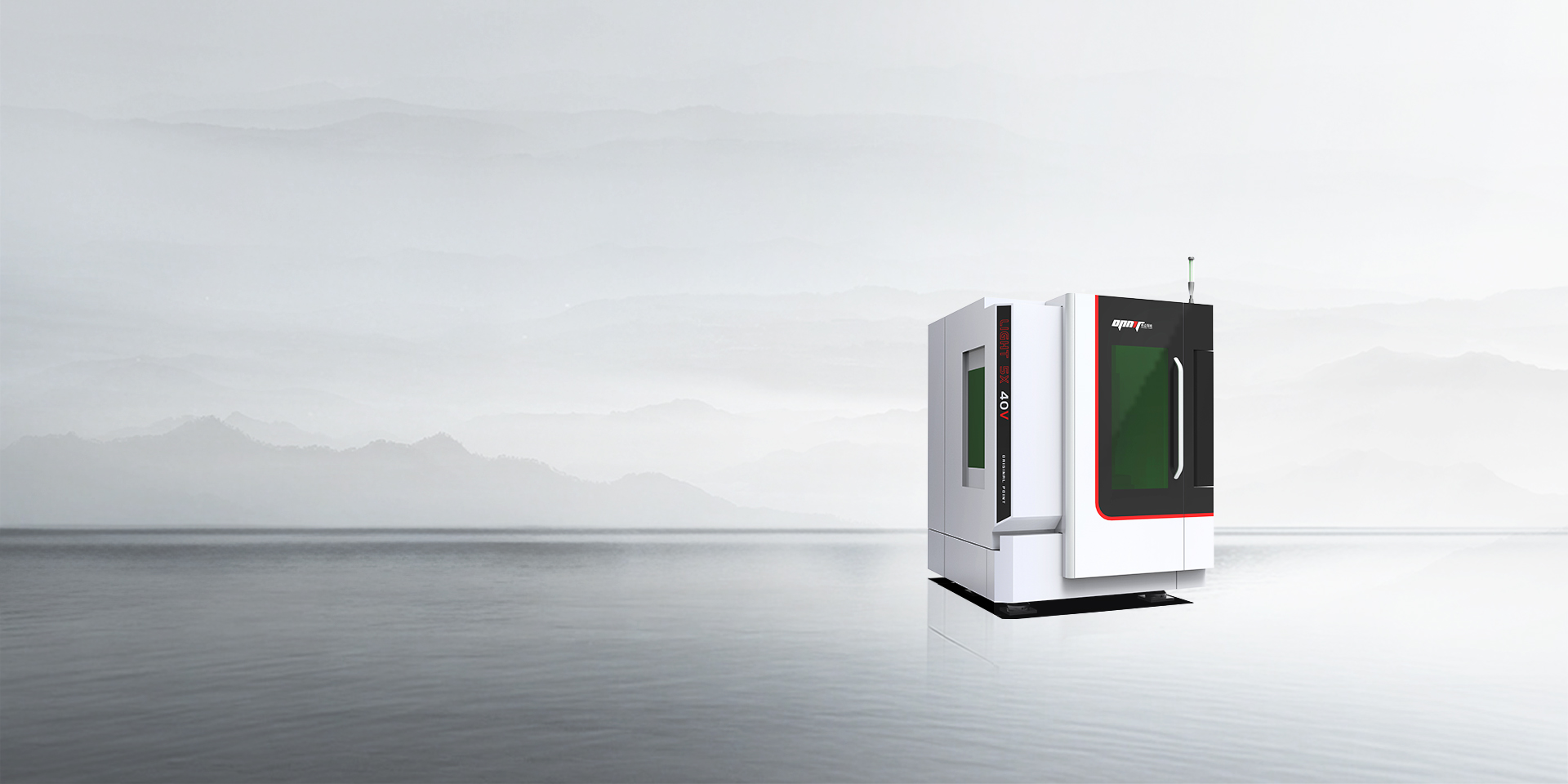

For more complex diamond processing applications, OPMT offers the Light 5X 40V and Light 5X 60V vertical 5-axis laser machining centers that excel at processing diamond materials including PCD, CBN, and CVD diamond with unprecedented precision.

Key Specifications:

As stated in OPMT’s technical documentation: “This machine is widely used for machining of PCD, CBN, hard alloys, ceramics, metal and other materials, and can machine complex contours and profiles of welded-edge milling cutter, micro-edge tool, and thin-walled metal parts”.

Laser processing delivers significant advantages over conventional methods for CVD diamond processing:

| Performance Metric | Traditional EDM | OPMT Laser Systems | Improvement |

|---|---|---|---|

| Processing Speed | 1 mm/min | Up to 3.0 mm/min | 3× faster |

| Edge Quality | Chips and cracks common | No edge chipping at 200× magnification | Superior quality |

| Material Flexibility | Conductive materials only | All diamond types including non-conductive CVD | Expanded capability |

| Processing Accuracy | ≥0.015 mm | ≤0.005 mm | 3× better |

| Heat Affected Zone | Significant | Minimal (<5μm with femtosecond) | Superior preservation of material properties |

The non-contact nature of laser processing eliminates tool wear while maintaining consistent quality with “edge passivation capabilities of 0.004-0.005 mm” and “surface roughness less than 0.1 μm” for diamond materials.

OPMT’s diamond processing systems feature sophisticated control technologies:

The integration of RTCP (Rotational Tool Center Point) 5-axis linkage technology enables the machines to maintain precise tool positioning relative to workpieces while executing complex multi-axis movements – essential for creating intricate features in diamond components.

CVD diamond’s exceptional thermal conductivity makes it ideal for electronic applications where heat management is critical:

The 3C Electronic Digital Industry Solutions offered by OPMT enable precise processing of diamond components for these applications with dimensional tolerances reaching 0.003mm.

In the automotive sector, processed diamond components offer exceptional wear resistance and thermal management capabilities:

OPMT’s Solutions for the Automotive and Parts Industry address these applications with specialized laser processing capabilities.

Diamond’s superior hardness makes it the material of choice for cutting and machining applications:

The precision achieved with OPMT’s laser systems enables “the teeth section of a flooring cutter” and other specialized tooling applications requiring exceptional edge quality and dimensional accuracy.

CVD diamond’s broad optical transparency makes it valuable for specialized optical applications:

OPMT’s precision laser processing capabilities enable the creation of optical components with “surface roughness less than 0.1 μm” and “contour accuracy smaller than 10 μm”, essential for high-performance optical applications.

OPMT implements comprehensive quality assurance protocols for diamond processing:

These rigorous testing and certification systems ensure consistent quality in diamond component processing across production runs.

OPMT continues to advance diamond processing capabilities through several innovations:

CVD diamond technology represents a revolutionary advancement in materials science, with applications spanning electronics, automotive, tooling, and optical industries. OPMT Laser’s advanced diamond processing systems overcome the limitations of traditional machining methods, delivering unprecedented precision, efficiency, and quality for even the most demanding diamond component applications.

Key technical advantages include:

As synthetic diamond continues to gain importance across high-technology industries, OPMT Laser’s specialized diamond processing systems enable manufacturers to fully leverage the exceptional properties of this remarkable material while achieving the precision and quality demanded by the most challenging applications.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.