Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

The precision manufacturing landscape has undergone a transformative evolution with the advent of 5-axis laser machining technology, enabling unprecedented accuracy and efficiency in processing complex geometries across diverse industrial applications. This advanced manufacturing approach combines sophisticated laser systems with multi-axis positioning capabilities, delivering exceptional results in automotive tooling, 3C electronics, medical devices, and aerospace components. OPMT Laser’s comprehensive portfolio of 5-axis laser machining centers represents the cutting edge of this technological revolution, offering manufacturers the precision and flexibility required for next-generation production demands.

Modern 5-axis laser processing systems achieve positioning accuracies of ±0.005mm while maintaining rapid traverse speeds up to 30 m/min, significantly outperforming traditional machining methods in terms of both precision and productivity. The integration of advanced laser galvanometer technology with sophisticated multi-axis control systems enables manufacturers to process ultra-hard materials including PCD, CBN, ceramics, and advanced composites with exceptional surface quality and dimensional accuracy.

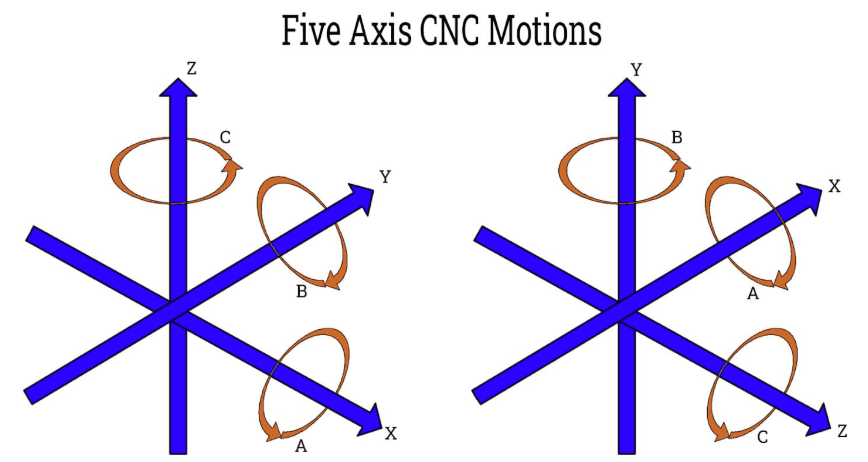

5-axis laser machining systems incorporate three linear axes (X, Y, Z) and two rotational axes (typically B and C), providing complete geometric freedom for complex part processing. This configuration enables simultaneous movement across all five axes, allowing the laser beam to maintain optimal angle and focus throughout the machining process regardless of workpiece complexity.

The fundamental advantage of 5-axis geometry lies in its ability to eliminate multiple setups and reduce accumulated tolerance errors. Unlike traditional 3-axis systems that require workpiece repositioning for complex geometries, 5-axis machines complete intricate parts in a single clamping operation, ensuring superior accuracy and significantly reduced cycle times.

Key Performance Parameters:

Modern 5-axis laser systems employ linear motor drives for all linear axes, providing exceptional dynamic response without mechanical backlash. The rotational axes utilize high-precision torque motors with direct drive configurations, ensuring smooth motion throughout the full range of angular movement. All axes implement full closed-loop grating scale feedback systems, delivering the precision required for demanding manufacturing applications.

The integration of sophisticated NUM CNC control systems provides comprehensive motion coordination with advanced features including RTCP (Rotation Tool Center Point) functionality. This capability ensures that the laser focal point remains precisely positioned during simultaneous multi-axis movements, critical for maintaining consistent processing quality across complex three-dimensional geometries.

5-axis laser machining demonstrates significant advantages over traditional processing methods, particularly in applications requiring complex geometries and ultra-hard material processing. The elimination of mechanical tool wear inherent in laser processing ensures consistent dimensional accuracy throughout production runs.

| Processing Method | Positioning Accuracy | Surface Roughness | Processing Speed | Tool Wear |

|---|---|---|---|---|

| 5-Axis Laser | ±0.005mm | Ra 0.1-0.3μm | 3x faster | None |

| Traditional EDM | ±0.010mm | Ra 0.3-0.8μm | Baseline | High electrode consumption |

| Grinding | ±0.008mm | Ra 0.2-0.5μm | 2x slower | Wheel wear/dressing required |

| Mechanical Milling | ±0.015mm | Ra 0.4-1.2μm | Variable | Tool replacement frequent |

The implementation of 5-axis laser machining technology delivers measurable economic benefits through multiple operational improvements. Processing time reductions of 200-300% compared to conventional EDM methods result in significant productivity gains, while the elimination of consumable electrodes and cutting tools reduces ongoing operational costs by approximately 50%.

Energy efficiency represents another crucial advantage, with femtosecond laser systems consuming 44% less energy than traditional thermal processing methods while eliminating chemical waste streams entirely. This environmental benefit aligns with modern sustainability requirements while reducing regulatory compliance costs.

The heart of advanced 5-axis laser machining lies in sophisticated galvanometer scanning systems that provide rapid, precise beam positioning capabilities. These electro-optical devices utilize high-speed mirrors to direct laser beams with positioning accuracies reaching ±1-2 microradians, enabling intricate pattern generation and complex contour processing.

OPMT’s advanced galvanometer systems operate at scanning frequencies exceeding 1,000 Hz while maintaining positioning stability within ±0.1 microradians per degree Celsius temperature variation. This thermal stability ensures consistent processing quality throughout extended production runs, critical for high-volume manufacturing applications.

Galvanometer System Specifications:

Medical device applications demand the highest levels of precision and surface quality, making 5-axis laser machining an ideal processing solution. FDA-compliant processing protocols ensure complete traceability and validation documentation required for medical device manufacturing regulations.

Critical medical device applications include:

The Micro3D L530V femtosecond system specifically addresses medical device requirements with pulse widths ≤400fs and repetition frequencies ≥1MHz, enabling “cold processing” that eliminates thermal damage in sensitive materials.

The rapid evolution of consumer electronics drives demand for increasingly precise manufacturing capabilities. 3C electronics applications require sub-micron accuracy for component processing, circuit board via drilling, and precision marking operations.

Key 3C Applications:

Performance data from 3C manufacturing implementations show 65% reduction in positioning-related defects and achievement of 99.97% process yield through optimized laser processing parameters.

OPMT Laser’s portfolio encompasses multiple 5-axis configurations optimized for specific application requirements. The following comparison highlights key specifications across the product range:

| Model | Travel Range (X/Y/Z) | Positioning Accuracy | Laser Power | Max Workpiece | Typical Applications |

|---|---|---|---|---|---|

| Light 5X-40V | 400/250/300mm | ±0.005mm | 100W | φ200 x 200mm | 3C electronics, PCD tools |

| Light 5X-60V | 600/250/300mm | ±0.005mm | 100W | φ350 x 200mm | Automotive tooling, aerospace |

| LP550V | 520/640/480mm | ±0.008mm | Variable | φ400 x 310mm | Rotary cutting, compound processing |

| Micro3D L530V | Custom configuration | ±0.010μm | 40W femtosecond | Variable | Ultra-precision, medical devices |

All OPMT 5-axis systems incorporate modular design architecture enabling function expansion and software upgrades throughout the equipment lifecycle. The direct drive indexing structure ensures high angular accuracy and excellent dynamic response characteristics across all rotational axes.

Standard Equipment Features:

Successful 5-axis laser machining implementation requires careful attention to environmental conditions and installation procedures. Optimal performance demands controlled temperature environments (±2°C variation), adequate power supply infrastructure, and proper vibration isolation.

Installation Requirements:

Achieving optimal results requires systematic approach to process parameter development and validation. Material-specific processing parameters must be established through controlled testing protocols, with documentation maintained for regulatory compliance requirements.

Optimization Methodology:

Preventive maintenance protocols ensure consistent long-term performance and maximize equipment uptime. Predictive maintenance strategies utilizing comprehensive system diagnostics enable optimization of maintenance schedules while minimizing unplanned downtime.

Maintenance Schedule Framework:

The next generation of 5-axis laser machining systems will incorporate machine learning algorithms for real-time process optimization and predictive quality control. AI-enhanced systems will automatically adjust processing parameters based on material variations, environmental conditions, and quality feedback, ensuring optimal results with minimal operator intervention.

Emerging AI Applications:

Advanced connectivity and data analytics capabilities enable seamless integration with digital manufacturing ecosystems. IoT-enabled systems provide comprehensive operational data for continuous improvement initiatives while supporting remote monitoring and diagnostic capabilities.

The evolution toward digital twin technology will enable virtual system modeling for process optimization and training applications. This approach provides continuous performance enhancement opportunities while reducing implementation risks for new applications.

5-axis laser machining technology represents a transformative advancement in precision manufacturing, offering unprecedented capabilities for complex geometry processing across diverse industrial applications. The combination of advanced laser systems, sophisticated motion control, and comprehensive automation delivers measurable improvements in productivity, quality, and operational efficiency.

OPMT Laser’s comprehensive portfolio provides optimized solutions for specific application requirements, from high-volume 3C electronics manufacturing to precision medical device production. The integration of advanced laser galvanometer systems with sophisticated 5-axis positioning capabilities enables manufacturers to achieve previously unattainable levels of precision and efficiency.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.