Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Laser galvanometers achieve beam positioning speeds exceeding 1,000 Hz with angular resolutions of ±1-2 microradians, enabling processing velocities up to 4,000 mm/s that surpass conventional mechanical systems by over 300%. This remarkable performance has positioned galvanometer scanning systems as the cornerstone of modern precision laser processing across aerospace, medical device manufacturing, automotive production, and advanced materials machining.

As manufacturing demands increasingly require higher throughput without compromising precision, laser galvanometer technology bridges the gap between traditional mechanical positioning systems and the ultra-high-speed requirements of Industry 4.0. This comprehensive guide explores the fundamental principles, performance characteristics, and practical implementation strategies for galvanometer-based laser scanning systems, supported by validated technical specifications from OPMT’s advanced 5-axis laser machining platforms.

Whether you’re evaluating laser galvanometer systems for high-volume marking operations, complex mold texturing applications, or precision cutting of superhard materials, understanding the underlying technology and performance trade-offs is essential for optimizing your manufacturing processes and achieving measurable ROI improvements.

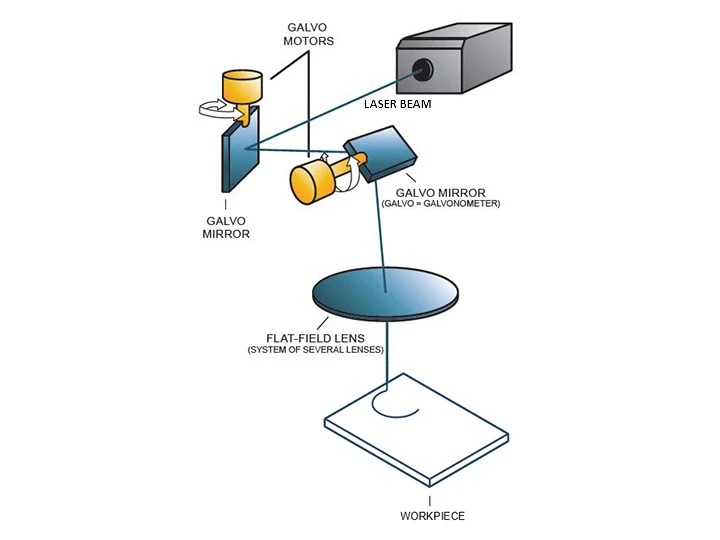

At its core, a laser galvanometer operates through precise electromechanical conversion, transforming electrical current into controlled angular deflection via a moving coil suspended within a carefully calibrated magnetic field. This elegant mechanism enables rapid, repeatable beam positioning that mechanical stage systems cannot match.

The fundamental architecture consists of a lightweight mirror mounted on a rotating shaft connected to the moving coil. When current flows through the coil, electromagnetic forces generate torque proportional to the input signal, rotating the mirror to a specific angle. This angular displacement directly controls the laser beam’s position on the target workpiece. Modern laser galvanometer systems achieve response times under 1 millisecond, enabling dynamic beam control at frequencies exceeding 1,000 Hz.

Industrial laser galvanometer systems employ two mirrors arranged perpendicular to each other, creating an X-Y scanning configuration. The first mirror (X-axis) controls horizontal beam deflection, while the second mirror (Y-axis) manages vertical positioning. This orthogonal arrangement enables complete two-dimensional laser beam positioning across the designated processing area with exceptional speed and precision.

The optical path design critically impacts system performance. The laser beam reflects sequentially off both mirrors before passing through focusing optics that converge the beam onto the workpiece surface. Careful calibration ensures that the focal point remains consistent across the entire scanning field, compensating for optical path length variations inherent in the dual-mirror geometry.

Advanced laser galvanometer systems incorporate closed-loop feedback mechanisms utilizing position sensors for real-time angular correction and precision maintenance. These sensors—typically optical encoders or capacitive position detectors—continuously monitor actual mirror position and compare it against commanded position. Any deviation triggers immediate corrective adjustments through the control system.

This feedback architecture delivers several critical advantages. Temperature fluctuations, mechanical vibrations, and magnetic field variations that would compromise open-loop accuracy are automatically compensated in real-time. The result is sustained precision across extended production runs, maintaining positioning accuracy within ±0.1 microradians per °C thermal drift.

Modern high-performance systems increasingly employ direct-drive torque motors rather than traditional moving-coil galvanometers for applications demanding maximum speed and acceleration. Torque motors eliminate mechanical linkages, reducing inertia and enabling faster response times. However, traditional galvanometer mechanisms remain optimal for applications prioritizing compact size, lower power consumption, and moderate performance requirements.

OPMT’s implementation in the Micro3D L530V platform demonstrates integrated galvanometer scanning achieving ±0.003mm positioning accuracy when synchronized with 5-axis mechanical motion—performance levels that validate closed-loop control effectiveness in production environments.

Understanding the fundamental distinction between closed-loop and open-loop galvanometer architectures is essential for matching system capabilities to application requirements and budget constraints.

Closed-loop laser galvanometer systems integrate position sensors that enable feedback-driven precision control for high-accuracy applications. These sensors continuously measure actual mirror position, feeding this data back to the control system for real-time error correction. The controller compares commanded position against actual position, generating corrective signals that minimize positioning errors.

This architecture delivers exceptional performance metrics. Angular resolution reaches 15 µrad (0.0008°), enabling positioning precision that translates to ±0.002mm repeatability in properly configured systems. Thermal stability is maintained through continuous compensation, ensuring consistent accuracy across temperature variations that would degrade open-loop performance by 10-20%.

The primary trade-off is cost. Closed-loop systems require additional hardware (position sensors, higher-performance controllers) and more sophisticated calibration procedures, typically commanding 40-60% price premiums over equivalent open-loop configurations.

Open-loop laser galvanometer systems operate without position feedback, relying on the inherent repeatability of the electromechanical conversion mechanism. Current input directly determines mirror position based on calibration curves established during system setup. While lacking real-time error correction, modern open-loop systems achieve surprisingly consistent performance for many industrial applications.

These systems excel in applications prioritizing speed over absolute positioning accuracy. Without feedback processing overhead, open-loop controllers achieve faster response times—beneficial for high-speed marking and engraving operations where throughput matters more than micron-level precision. Typical accuracy ranges from ±0.005mm to ±0.010mm under stable environmental conditions.

Cost efficiency represents the compelling advantage. Open-loop configurations deliver 60-70% of closed-loop performance at 40-50% of the investment, making them ideal for high-volume marking, PCB drilling, and other applications with moderate precision requirements.

Several factors should guide your choice between closed-loop and open-loop laser galvanometer systems:

Required Repeatability: Medical device marking, aerospace component identification, and precision cutting of superhard materials demand closed-loop accuracy. General product marking, packaging codes, and promotional engraving accept open-loop performance.

Processing Speed: If your application requires sustained operation above 2,000 mm/s scanning speeds, closed-loop systems maintain accuracy better at these velocities through continuous feedback correction.

Environmental Conditions: Production environments with significant temperature variations (±10°C or more) benefit substantially from closed-loop thermal compensation. Climate-controlled facilities enable reliable open-loop operation.

Budget Constraints: When capital investment is limited but throughput requirements are high, open-loop systems deliver compelling value. The cost differential can be reinvested in additional processing stations, multiplying overall production capacity.

OPMT’s Micro3D L570V platform integrates closed-loop galvanometer scanning for mold texturing applications where surface pattern fidelity directly impacts final product quality—a clear case where feedback-driven precision justifies the investment.

Laser galvanometer technology has penetrated virtually every advanced manufacturing sector, enabling process innovations that were technically or economically infeasible with traditional mechanical positioning systems.

High-volume production marking represents the largest application category for laser galvanometer systems, leveraging speeds up to 4,000 mm/s to mark automotive components, electronics assemblies, and consumer products. The automotive industry extensively deploys galvanometer-based marking for vehicle identification numbers (VINs), engine component traceability codes, and date/lot marking on safety-critical parts.

Electronics manufacturers utilize galvanometer marking for PCB serial numbers, component identification, and QR code application at rates exceeding 100 parts per minute. The non-contact nature eliminates tool wear while the high-speed positioning minimizes cycle time impact—critical factors when marking adds value without reducing throughput.

Selective laser sintering (SLS) and selective laser melting (SLM) additive manufacturing processes rely fundamentally on galvanometer scanning systems. These systems execute rapid layer-by-layer construction, selectively melting or sintering metal powders according to CAD-derived scan patterns. The galvanometer’s ability to traverse complex geometries at 1,000+ mm/s while maintaining precise energy deposition enables practical build rates for metal 3D printing.

Modern metal additive manufacturing systems employ dual galvanometer configurations, allowing parallel processing of different build regions to further increase productivity. Some advanced platforms integrate up to four independent galvanometer scanning heads, quadrupling effective build speed for large-format parts.

OPMT’s Micro3D L570V achieves precise surface patterning via nanosecond and femtosecond laser integration with galvanometer scanning. This application creates functional surface textures on injection molds—patterns that transfer to molded plastic parts, eliminating secondary finishing operations.

The galvanometer executes microscopic pattern elements (dimples, grooves, crosshatch patterns) at high speed while 5-axis mechanical positioning orients the workpiece for comprehensive mold coverage. Pattern consistency across large mold surfaces depends critically on galvanometer repeatability, making closed-loop systems standard for this demanding application.

Sub-micron precision marking on medical implants and surgical instruments requires biocompatible processing that laser galvanometer systems uniquely provide. The non-contact process introduces no contamination while achieving the fine detail necessary for UDI (Unique Device Identification) compliance mandated by FDA regulations.

Orthopedic implants, cardiovascular stents, and surgical instruments receive laser-marked serial numbers, lot codes, and manufacturer identification using galvanometer systems optimized for small characters (0.3mm height) and high contrast on difficult materials including titanium alloys, cobalt-chrome, and stainless steel.

Vision-guided laser processing systems integrate galvanometer scanning with machine vision for automated quality control applications. The vision system identifies features requiring marking or modification, while the galvanometer executes rapid repositioning for inspection and material handling in production lines. This combination enables adaptive processing where mark content or location varies part-to-part based on real-time inspection results.

The convergence of galvanometer scanning technology with multi-axis CNC motion control represents a paradigm shift in laser processing capabilities, enabling complex geometries and processing strategies previously unachievable with either technology alone.

Hybrid systems coordinate galvanometer optical scanning with mechanical axes through sophisticated motion control algorithms that maintain precise spatial relationships between beam position and workpiece geometry. The CNC controller orchestrates both subsystems, calculating synchronized motion commands that account for different response characteristics—mechanical axes with higher inertia but unlimited travel range, galvanometer mirrors with minimal inertia but limited angular deflection.

This synchronization enables “scan-on-the-fly” processing where the mechanical axes position the workpiece along a primary path while galvanometer mirrors execute high-speed scanning perpendicular to that motion. The technique dramatically increases effective processing speed for linear features like welding seams or cutting paths that exceed galvanometer field-of-view limits.

RTCP (Real-Time Tool Center Point) control maintains perpendicular beam incidence on curved surfaces by continuously adjusting mechanical axis positions as the galvanometer scans across the workpiece. This advanced control strategy is essential for processing complex 3D geometries where surface normal vectors vary significantly across the scanning field.

The control algorithm calculates required mechanical axis adjustments in real-time based on workpiece geometry (from CAD models), current galvanometer mirror positions, and beam delivery optics characteristics. OPMT’s implementation achieves update rates exceeding 1 kHz, ensuring smooth motion coordination without velocity discontinuities that would compromise surface finish.

The synergy between mechanical positioning and optical scanning delivers compelling benefits:

Extended Processing Area: Mechanical axes provide unlimited travel range while galvanometer mirrors execute high-speed scanning within smaller fields-of-view (typically 100-300mm). The combination enables processing large workpieces without sacrificing the speed advantages of galvanometer scanning.

Optimized Speed Profiles: Long-distance positioning utilizes mechanical axes; intricate patterns employ galvanometer scanning. The controller automatically partitions the processing task, assigning motion segments to the optimal subsystem based on distance, required precision, and speed requirements.

Enhanced Throughput: Parallel motion capability allows mechanical axes to position the next workpiece while galvanometer scanning completes processing on the current part—an overlap impossible with single-technology systems.

Integrating galvanometer scanning with 5-axis mechanical motion requires specialized beam delivery optics that maintain focus across the extended working envelope. Focus compensation algorithms account for surface geometry variations, automatically adjusting focus position as mechanical axes reorient the workpiece.

Dynamic focus systems employ programmable focal length adjustment, typically achieved through motorized lens positioning or adaptive optics. These systems receive commands synchronized with mechanical axis and galvanometer motion, ensuring optimal focus regardless of beam incidence angle or working distance variations.

OPMT’s Micro3D L530V and L570V platforms demonstrate practical galvanometer integration, achieving ±0.003mm positioning accuracy when combining 5-axis RTCP motion with closed-loop galvanometer scanning. These systems process PCD (polycrystalline diamond) cutting tool inserts, CVD diamond coatings, and ceramic components—materials demanding exceptional precision across complex 3D geometries.

The 5-axis laser machining architecture employed in these platforms has been validated across 300+ production deployments, confirming that synchronized galvanometer-mechanical control delivers measurable productivity improvements (40-60% cycle time reductions) versus sequential processing approaches.

Understanding laser galvanometer performance parameters enables accurate system selection and realistic performance expectations for your specific application requirements.

Angular resolution defines the smallest angular increment the galvanometer can reliably execute. High-performance closed-loop systems achieve ±1-2 microradians—a specification that translates to approximately ±0.001mm linear positioning at typical working distances (100-200mm). This microradian-level precision enables applications like micro-machining, precision drilling of cooling holes in turbine blades, and high-resolution marking on medical devices.

Linear positioning accuracy depends on both angular resolution and working distance (the distance from galvanometer mirrors to workpiece surface). The relationship is geometric: positioning error equals angular error multiplied by working distance. Consequently, maintaining ±0.002mm repeatability requires either exceptional angular precision or reduced working distances.

Thermal stability specifications quantify accuracy degradation across temperature variations. Premium galvanometer systems maintain ±0.1 µrad/°C drift, ensuring that ±10°C ambient temperature swings (common in production environments) introduce less than ±1 µrad positioning error—negligible for most applications.

Operational velocities reaching 4,000 mm/s represent a 233% improvement over traditional mechanical stage systems operating at 1,200 mm/s maximum speeds. This velocity advantage directly impacts productivity for high-volume applications. A marking operation requiring 2.5 seconds at 1,200 mm/s completes in under 1 second at 4,000 mm/s—a 60% cycle time reduction that multiplies daily throughput accordingly.

Maximum acceleration rates determine how quickly the galvanometer reaches target velocity, particularly important for processing patterns with frequent direction changes. High-performance systems achieve 15,000-25,000 rad/s² acceleration, enabling sharp corners and intricate patterns without velocity-limiting slowdowns.

Galvanometer scanning field size depends on mirror aperture dimensions, focal length, and maximum angular deflection. Typical industrial systems provide 100mm × 100mm to 300mm × 300mm square fields at standard working distances (200-400mm). Larger fields are achievable through longer focal length optics, though this increases working distance and potentially compromises positioning precision.

The relationship between field size and accuracy creates an important trade-off. Larger fields distribute angular positioning errors across greater distances, amplifying linear positioning deviations. Applications requiring both large processing areas and high precision benefit from hybrid galvanometer-mechanical axis architectures that partition the workspace.

Repeatability—the ability to return to the same position across multiple cycles—often matters more than absolute accuracy for production applications. Galvanometer systems exhibit exceptional repeatability because the same electromechanical conversion mechanism operates for every positioning command without cumulative mechanical wear.

OPMT production systems achieve ±0.002mm repeatability versus industry-standard specifications of ±0.005mm. This superior consistency ensures that multi-pass processing operations (roughing followed by finishing, for example) maintain precise spatial registration between passes—critical for quality in precision cutting and surface texturing applications.

Modern laser galvanometer mirrors accommodate nanosecond, picosecond, and femtosecond laser sources across 20-500W average power ranges. Mirror coatings are optimized for specific wavelengths (1064nm fiber lasers, 532nm frequency-doubled lasers, 355nm UV lasers) and pulse durations. High-damage-threshold coatings withstand peak power densities exceeding 10 GW/cm² for ultrafast laser applications.

Thermal management becomes critical at higher average powers. Mirror substrates with high thermal conductivity (silicon carbide, beryllium) and active cooling systems prevent thermal distortion that would degrade beam quality and positioning accuracy during sustained high-power operation.

Objective evaluation of laser galvanometer technology requires understanding both capabilities and constraints relative to alternative positioning technologies.

The speed differential versus mechanical stage systems fundamentally changes process economics. High-volume production marking operations achieve 40-60% cycle time reductions, translating to proportional throughput increases without additional capital investment in processing stations. For contract manufacturers operating on thin margins, this productivity multiplication delivers measurable competitive advantage.

Speed benefits extend beyond simple throughput. Faster processing minimizes heat-affected zones in thermal-sensitive materials, reduces thermal distortion in thin-walled components, and enables multi-pass strategies that improve surface finish without excessive cycle time penalties.

Sub-micron positioning enables intricate detail work essential for medical implants, microelectronics fabrication, and precision optics manufacturing. Character heights below 0.3mm remain legible, feature sizes approach 10-20 µm limits (depending on laser spot size), and pattern placement accuracy supports tolerance-critical applications.

This precision extends to repeatability across production volumes. Unlike mechanical systems subject to wear-induced degradation, galvanometer performance remains stable across millions of operation cycles, ensuring that the first part and the millionth part meet identical quality standards.

Effective processing spans metals (stainless steel, titanium, aluminum, copper alloys), plastics (ABS, polycarbonate, acrylic), ceramics (alumina, zirconia), and superhard materials including PCD, CBN, and CVD diamond. The non-contact process adapts to diverse material properties without tooling changes—a single galvanometer system handles marking, cutting, drilling, and surface texturing across this material spectrum.

Fewer moving parts versus belt-driven or ball-screw mechanical systems translate to reduced maintenance requirements and longer service intervals. Galvanometer systems typically operate 5,000-10,000 hours between scheduled maintenance versus 2,000-3,000 hours for equivalent mechanical stages. This extended uptime reduces operational costs and minimizes production disruptions.

Limited field size compared to gantry systems represents the primary limitation requiring strategic application selection. Applications processing workpieces larger than 300mm × 300mm must either accept multiple repositioning cycles (reducing throughput advantages) or employ hybrid architectures combining galvanometer scanning with mechanical axis positioning.

Field size expansion through longer focal length optics introduces working distance increases that may conflict with space constraints in existing production cells. Careful layout planning is essential to accommodate the beam delivery path requirements.

Sustained high-speed operation generates heat within galvanometer motors and mirror substrates. Without adequate thermal management, this heat causes positioning drift and accuracy degradation. Industrial systems incorporate active cooling (water or forced air) to maintain thermal stability, adding complexity and infrastructure requirements.

Environmental temperature control becomes more critical for galvanometer systems than mechanical alternatives. Maintaining ±5°C ambient stability ensures consistent performance, whereas mechanical systems tolerate wider temperature variations with less impact on accuracy.

OPMT’s implementation demonstrates balanced design addressing these limitations. The L570V mold texturing platform combines galvanometer scanning for high-speed pattern execution with 5-axis mechanical positioning for comprehensive mold coverage—a practical solution that maximizes throughput while eliminating field-of-view constraints.

Matching laser galvanometer capabilities to application requirements demands systematic analysis across multiple technical and economic dimensions.

Begin with precision demands. Applications requiring ±0.002mm repeatability necessitate closed-loop systems; those accepting ±0.005-0.010mm accuracy can leverage cost-effective open-loop configurations. Document actual tolerance requirements from part drawings rather than specifying “maximum precision”—over-specification increases costs without improving outcomes.

Processing speed requirements determine whether standard galvanometer systems suffice or whether hybrid architectures combining optical scanning with mechanical positioning deliver better value. Applications processing features smaller than 100mm × 100mm at speeds exceeding 1,000 mm/s represent ideal galvanometer candidates. Larger features benefit from mechanical axis integration.

Material compatibility assessment ensures the selected laser source and galvanometer mirror coatings optimize performance for your specific materials. Different wavelengths exhibit vastly different absorption characteristics: 1064nm fiber lasers excel on metals but struggle with transparent plastics; 355nm UV lasers mark plastics effectively but require higher power for metal processing.

Pulse duration compatibility affects both process quality and galvanometer mirror requirements. Nanosecond lasers provide cost-effective marking and engraving with minimal heat-affected zones. Picosecond and femtosecond sources enable ultra-precision processing with virtually no thermal damage—essential for medical devices and microelectronics but commanding significant cost premiums.

Power handling requirements must account for both average power and peak pulse energy. Galvanometer mirrors specify maximum continuous power (typically 50-500W average) and peak fluence (J/cm²) limits. Exceeding either specification causes mirror damage requiring costly replacement.

Wavelength optimization balances material absorption characteristics against available galvanometer mirror coatings. Standard coatings accommodate 1064nm (fiber lasers), 532nm (frequency-doubled), and 355nm (UV) wavelengths. Specialized coatings enable CO₂ lasers (10.6 µm) for organic materials processing.

Standalone galvanometer controllers offer simplicity and lower cost for applications requiring only optical scanning without mechanical axis coordination. These systems accept standard file formats (DXF, PLT, bitmap images) and execute marking/engraving operations independently.

Integrated CNC platforms with multi-axis synchronization enable hybrid architectures combining galvanometer scanning with mechanical positioning. These sophisticated controllers coordinate motion commands across all axes, implementing RTCP algorithms and synchronized scanning strategies. OPMT’s NUM-based control system demonstrates this integration, achieving seamless coordination between 5 mechanical axes and galvanometer scanning.

Focal length optimization balances field size requirements against working distance constraints. Shorter focal lengths (100-160mm) provide compact configurations but limit field size to 70-110mm. Longer focal lengths (250-420mm) enable 175-300mm fields but require greater clearance between optics and workpiece.

Working distance requirements must accommodate workpiece geometry, fixturing, and potential interference with surrounding equipment. Three-dimensional workpieces may require additional standoff distance to prevent collisions during multi-axis motion.

Field size calculations should provide 10-15% margin beyond actual processing requirements to accommodate calibration variations and edge-field optical aberrations that can degrade performance at field extremities.

Closed-loop premium pricing typically adds 40-60% to system cost versus open-loop equivalents. This investment is justified when application accuracy requirements exceed open-loop capabilities or when environmental conditions (temperature variations, vibration) would compromise open-loop performance.

Total cost of ownership analysis should account for maintenance requirements, consumable costs (mirrors, protective windows), and downtime expenses. Galvanometer systems typically demonstrate lower ownership costs than mechanical alternatives despite higher initial investment, recovering the premium within 18-24 months in high-utilization applications.

Technical support capabilities matter significantly for first-time galvanometer users. Vendors offering application development assistance, training programs, and responsive troubleshooting support reduce implementation risk and accelerate time-to-production.

Customization options enable tailoring systems to specialized requirements. OPMT provides custom manufacturing processes integrating galvanometer scanning with application-specific fixturing, material handling automation, and quality control systems—turnkey solutions that minimize integration complexity.

Integration services including calibration, installation support, and process optimization help bridge the gap between purchased equipment and production-ready systems generating revenue.

Laser galvanometer technology continues advancing along multiple trajectories, promising significant performance improvements and expanded application opportunities.

Machine learning algorithms are emerging that analyze processing parameters (speed, acceleration, scanning patterns) against quality outcomes, automatically optimizing motion commands for efficiency maximization. These AI systems learn from production data, continuously refining motion strategies to minimize cycle time while maintaining quality specifications.

Real-time path planning algorithms enable adaptive processing where scanning strategies adjust dynamically based on in-process feedback from vision systems or process monitoring sensors. This capability supports applications like automated defect repair where processing actions depend on real-time inspection results.

Advanced cooling technologies including thermoelectric coolers and microchannel heat exchangers enable sustained operation at higher scanning frequencies without thermal drift. These systems maintain mirror temperatures within ±1°C despite continuous high-speed operation, preserving positioning accuracy across extended production shifts.

Thermal modeling integrated into control systems predicts temperature-induced positioning errors, applying real-time compensation that further improves accuracy under thermal load conditions. This predictive approach eliminates thermal stabilization delays, enabling full-performance operation immediately after system startup.

Compact galvanometer designs achieving 50 cm³ volume targets enable integration into space-constrained applications including handheld laser processing tools and compact medical devices. These miniaturized systems maintain performance specifications comparable to larger industrial units through advanced materials and optimized electromagnetic designs.

Micro-galvanometer technology supports emerging applications in consumer electronics, wearable devices, and portable inspection equipment where traditional galvanometer sizes prove prohibitive.

Parallel processing configurations employing multiple independent galvanometer scanning heads enable productivity multiplication for large-area processing. Additive manufacturing systems already leverage dual and quad-beam architectures; this approach is expanding into marking and cutting applications where throughput demands justify the additional complexity.

Beam-splitting optics distribute a single laser source across multiple galvanometer scanners, maximizing laser utilization while multiplying effective processing speed. Advanced control systems coordinate multiple scanners, optimizing workload distribution and preventing beam path interference.

IoT connectivity enables galvanometer systems to communicate performance data, maintenance alerts, and quality metrics to manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. This integration supports data-driven decision-making and enables predictive maintenance strategies that minimize unplanned downtime.

Digital twin technologies create virtual models of galvanometer systems, simulating performance under various conditions to optimize process parameters before production implementation. These virtual commissioning capabilities reduce setup time and minimize trial-and-error experimentation on physical systems.

Predictive maintenance algorithms analyze operational data (motor temperatures, positioning errors, vibration spectra) to identify developing issues before they cause failures. Early intervention reduces repair costs and prevents quality defects associated with degraded performance.

Silicon carbide and beryllium mirror substrates reduce inertia while improving thermal conductivity, enabling faster acceleration profiles and better thermal stability. These advanced materials support next-generation galvanometer systems targeting 20,000+ rad/s² acceleration rates—a 30-40% improvement over current high-performance systems.

Lightweight mirrors combined with more powerful drive motors will push scanning speeds beyond 5,000 mm/s, further expanding the productivity advantage versus mechanical positioning systems and enabling new applications where current speeds prove insufficient.

Laser galvanometer technology represents a transformative advancement in precision manufacturing, delivering speed and accuracy combinations unattainable through traditional mechanical positioning systems. With beam positioning velocities reaching 4,000 mm/s and angular resolutions of ±1-2 microradians, these systems enable productivity improvements exceeding 300% while maintaining the sub-micron precision demanded by aerospace, medical device, and advanced materials processing applications.

The fundamental choice between closed-loop and open-loop architectures depends critically on application-specific requirements for repeatability, environmental conditions, and budget constraints. While closed-loop systems command premium pricing, their feedback-driven precision justifies investment for tolerance-critical applications. Open-loop configurations deliver compelling value for high-volume marking and moderate-precision operations.

Integration with 5-axis CNC platforms, as demonstrated by OPMT’s Micro3D L530V and L570V systems, represents the industry’s trajectory—hybrid architectures that combine galvanometer scanning speed with mechanical axis versatility. This convergence enables complex geometries and extended processing areas while preserving the throughput advantages that make galvanometer technology economically compelling.

As manufacturing continues evolving toward Industry 4.0 paradigms emphasizing connectivity, automation, and data-driven optimization, laser galvanometer systems will increasingly incorporate AI-driven motion planning, predictive maintenance capabilities, and seamless MES integration. These advances promise further performance improvements and expanded application opportunities across virtually every advanced manufacturing sector.

For manufacturers evaluating laser galvanometer systems, success depends on systematic analysis of application requirements, realistic performance expectations, and strategic vendor selection. OPMT’s comprehensive portfolio of integrated laser processing solutions provides proven platforms backed by technical expertise, customization capabilities, and support services that minimize implementation risk while accelerating time-to-value.

Ready to explore how laser galvanometer technology can transform your manufacturing processes? Contact OPMT’s technical team to discuss your specific application requirements and discover customized solutions that deliver measurable productivity improvements and competitive advantage.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Discover how advanced vertical 5-axis CNC systems achieve ±0.001-0.005mm micron-level precision for aerospace, medical, and automotive applications in 2026.

Comprehensive guide to 5-axis laser cutting machines: technology principles, advantages over 3-axis systems, industrial applications, and specifications for precision manufacturing.

Discover how 5-axis laser engraving machines deliver micron-level precision for complex surface marking, mold texturing, and industrial component identification across aerospace, automotive, and medical sectors.

Discover 5-axis machining operations including simultaneous, indexed positioning, and configuration types. Learn cutting methods for aerospace, medical & automotive applications.

Please fill in your contact information to download the PDF.