Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Water-guided laser technology represents a transformative advancement in precision manufacturing, combining high-intensity laser energy with controlled water jet streams to achieve superior cutting quality for heat-sensitive materials. This innovative approach addresses critical challenges in automotive, aerospace, electronics, and medical device manufacturing where thermal damage, material distortion, and contamination must be eliminated to meet stringent quality specifications. The technology demonstrates measurable performance improvements including 40-60% reduction in heat-affected zone width compared to conventional laser cutting methods, while maintaining production efficiency and enabling precise processing of materials ranging from carbon fiber composites to biomedical implants.

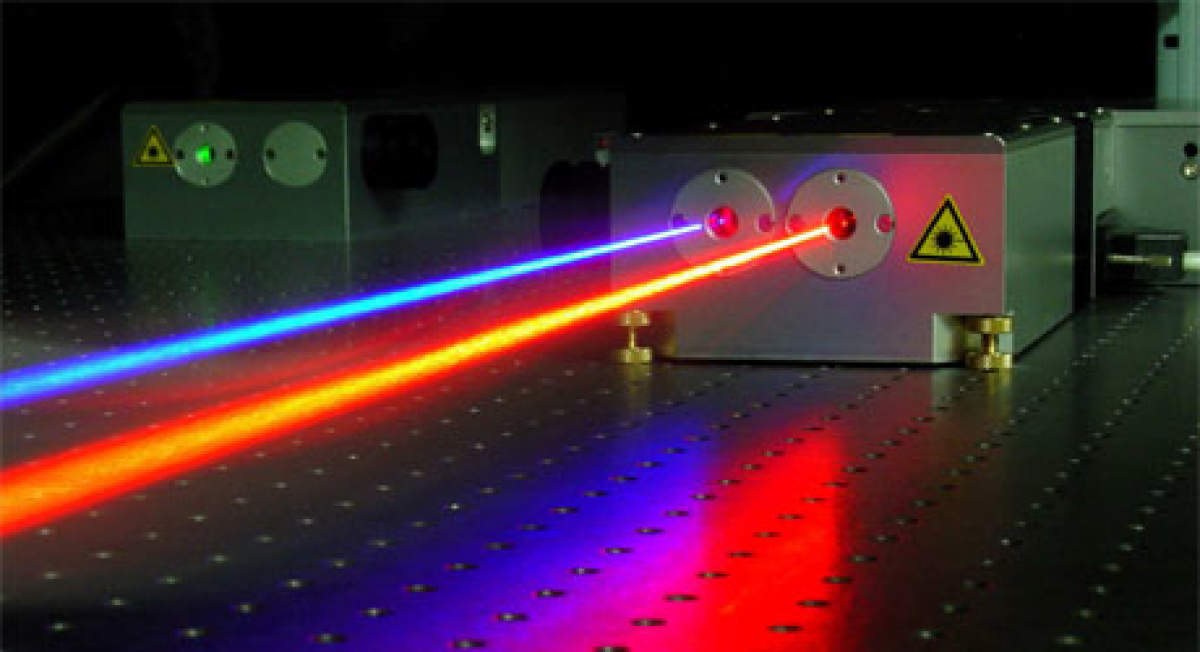

Water-guided laser systems operate on the principle of total internal reflection within a precisely controlled high-pressure water stream. The laser beam, typically generated by fiber laser sources with wavelengths between 1030-1070nm, couples into the water jet through specialized optical systems. The water stream functions as a flexible optical waveguide, maintaining beam coherence while providing simultaneous cooling and debris removal capabilities.

The physics underlying this process involves several critical parameters that directly impact cutting performance. Water flow pressures typically range from 300-800 bar, with optimal transmission efficiency achieved between 400-600 bar for most industrial applications. At these pressures, the water jet maintains laminar flow characteristics essential for consistent beam propagation and cutting quality.

Laser power transmission efficiency in water-guided systems reaches 85-92% under optimal conditions, comparing favorably to traditional fiber-delivered systems. The transmission mechanism relies on maintaining precise numerical aperture matching between the incident laser beam and the water waveguide. Critical design parameters include:

Optical System Components:

The water jet parameters directly influence cutting performance, with jet velocity ranging from 150-300 m/s depending on pressure settings. Jet straightness must be maintained within <5 micrometers deviation over 10mm length to ensure consistent cutting quality. Temperature regulation systems maintain operational ranges between 18-22°C for optimal performance stability.

Carbon fiber reinforced polymers (CFRP) present unique manufacturing challenges due to their heterogeneous structure and sensitivity to thermal damage. Traditional cutting methods often result in delamination, fiber pull-out, and matrix degradation that compromise structural integrity. Water-guided laser technology has demonstrated superior performance in automotive lightweighting applications.

For comprehensive understanding of multi-axis cutting capabilities with CFRP materials, manufacturers often integrate 5-axis laser machining systems to achieve complex geometries while maintaining thermal control. The key technical parameters for CFRP processing include:

Modern electronics manufacturing demands extreme precision with zero tolerance for thermal damage in semiconductor substrates, flexible circuits, and micro-electronic assemblies. Water-guided laser technology enables cutting of silicon wafers, gallium arsenide substrates, and polyimide flexible circuits with unprecedented precision.

Technical performance metrics for electronics applications demonstrate significant advantages:

Silicon Wafer Processing Parameters:

Flexible Circuit Processing Specifications:

The biomedical industry requires materials processing that maintains biocompatibility while achieving surgical-grade precision. Water-guided laser systems excel in processing medical-grade polymers, bioabsorbable materials, and composite implant components where contamination and thermal degradation must be eliminated.

For specialized medical applications, manufacturers often utilize precision laser texturing technology to create surface modifications that enhance biointegration properties. Material-specific parameters for biomedical applications include:

Nitinol Shape Memory Alloys:

PEEK Medical Polymers:

| Performance Parameter | Conventional Laser | Water-Guided Laser | Improvement Factor |

|---|---|---|---|

| Heat-Affected Zone Width | 100-300 μm | 20-80 μm | 60-75% reduction |

| Edge Roughness (Ra) | 1.5-4.0 μm | 0.3-1.2 μm | 70-80% improvement |

| Thermal Distortion | 50-200 μm | <10 μm | 95% reduction |

| Contamination Levels | Moderate-High | Minimal | 90% reduction |

| Secondary Processing | 30-60% of parts | <5% of parts | 85% elimination |

| Power Transmission Efficiency | 75-85% | 85-92% | 8-12% improvement |

| Cutting Speed (thin materials) | 1-5 m/min | 2-8 m/min | 40-60% faster |

Modern water-guided laser installations require comprehensive integration of multiple subsystems designed for industrial production environments. The architecture includes laser generation, beam delivery, water management, motion control, and process monitoring systems.

Laser Generation Systems:

Industrial installations predominantly utilize fiber laser sources with power levels ranging from 200W to 2000W. Selection criteria focus on beam quality (M² <1.1), power stability (±1%), and wavelength optimization for specific material absorption characteristics conforming to ISO 11145 standards.

Water Management Infrastructure:

High-pressure water systems require specialized components including high-pressure pumps capable of 1000+ bar operation, pressure regulation systems with response times <50ms, water filtration systems maintaining <1 micrometer particle size, and temperature control systems with ±0.5°C stability.

Successful water-guided laser implementation requires comprehensive evaluation of existing manufacturing processes, facility infrastructure, and quality requirements. Critical assessment areas include power supply requirements (400V, 3-phase, 50-100kW depending on system configuration), water supply specifications (minimum 50 l/min at 4 bar inlet pressure), and environmental controls maintaining temperature stability ±2°C with humidity <60%.

Advanced manufacturing facilities often implement AI-driven process control systems to optimize cutting parameters automatically based on material properties and quality requirements. This integration enables real-time adjustment of laser power, water pressure, and cutting speed to maintain consistent output quality.

Phase 1: Infrastructure Preparation (2-3 weeks)

Phase 2: Equipment Installation (1-2 weeks)

Phase 3: Process Validation (2-4 weeks)

Optimal parameter selection depends on material properties, thickness requirements, edge quality specifications, and production throughput targets. Field experience from manufacturing installations demonstrates that systematic optimization follows a specific sequence:

Optimization Sequence:

Parameter Ranges for Different Applications:

Thin Section Processing (0.1-2.0mm):

Medium Thickness Applications (2-10mm):

Modern water-guided laser installations incorporate advanced monitoring systems providing real-time feedback on cutting quality, process stability, and system performance. These systems enable immediate process correction and maintain consistent output quality throughout production runs.

Integrated Monitoring Systems:

Advanced installations implement closed-loop control systems that automatically adjust process parameters based on real-time monitoring feedback. These systems demonstrate significant improvements in production consistency and quality outcomes, with feedback control loops maintaining water pressure regulation within <1% variation and laser power stability at ±0.5% output.

For facilities requiring maximum precision and quality consistency, precision manufacturing solutions integrate multiple monitoring technologies to ensure compliance with stringent quality standards including ISO 9001 and AS9100 aerospace requirements.

Water-guided laser systems require higher initial capital investment but demonstrate superior total cost of ownership through reduced secondary processing, improved yield rates, and enhanced product quality. Capital investment analysis typically shows:

Operational cost benefits become apparent through multiple factors including secondary processing elimination (30-50% cost reduction), improved yield rates (15-25% material cost savings), reduced inspection requirements (20-35% quality cost reduction), and extended operational life with minimal consumable replacement needs.

Case study analysis from aerospace component manufacturing demonstrates payback periods typically ranging from 18-24 months, with 5-year net present value calculations showing positive returns of 150-200% at standard discount rates.

Water-guided laser systems must comply with comprehensive safety regulations including IEC 60825 for laser safety classification and relevant high-pressure equipment standards. Most industrial systems operate as Class 4 laser products, requiring controlled access areas with interlocked safety systems, personal protective equipment meeting EN 207 specifications, and comprehensive safety training programs.

Medical device manufacturing applications require additional compliance with FDA 21 CFR Part 820 Quality System Regulation and ISO 13485:2016 medical device standards. These requirements mandate comprehensive documentation, validation protocols, and quality management systems.

Water-guided laser systems offer significant environmental advantages through closed-loop water recycling achieving 95%+ recovery rates, minimal chemical additive requirements, reduced waste heat generation, and optimized material utilization. Energy efficiency improvements stem from higher material utilization through precise cutting, elimination of secondary processing energy requirements, and optimized laser efficiency through beam guiding technology.

Current technological developments focus on enhanced automation integration, AI-driven process parameter optimization, and expanded material compatibility through advanced beam shaping optics. Industry 4.0 connectivity features enable integration with factory-wide manufacturing execution systems, including real-time production data streaming, predictive maintenance algorithms based on machine learning analysis, and quality data integration with statistical process control systems.

Water-guided laser technology continues expanding into new material applications including advanced ceramics for aerospace applications, next-generation composite materials incorporating carbon nanotubes, and specialized biocompatible materials for medical implants. These developments require continuous advancement in process control algorithms and beam delivery systems.

Water-guided laser technology represents a thoroughly validated advancement in precision manufacturing, specifically engineered for applications involving heat-sensitive materials where conventional cutting methods fail to meet stringent quality specifications. The technology’s documented performance across automotive, aerospace, electronics, and medical device manufacturing environments confirms its capability to address critical thermal management, precision tolerance, and contamination control requirements.

Manufacturing engineers evaluating precision cutting solutions should prioritize water-guided laser technology for applications requiring thermal damage limitation below 50 micrometers, contamination prevention in cleanroom environments, and edge quality consistency meeting Ra <1.0 micrometer specifications. Implementation success requires systematic evaluation of application requirements, proper system configuration, and commitment to operational excellence through preventive maintenance and continuous process optimization.

Organizations considering this technology should conduct comprehensive total cost of ownership analysis incorporating quality improvements, secondary processing elimination, and long-term operational efficiency gains. The technology’s proven performance across diverse industrial applications, supported by ongoing research and development investments, ensures continued relevance in advanced manufacturing environments operating under increasingly stringent quality and regulatory requirements.

For facilities seeking to implement cutting-edge laser technology solutions, comprehensive consultation with experienced laser system specialists ensures optimal system configuration and successful technology transfer for maximum manufacturing productivity and quality achievement.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.