Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

CORE CUT CUTTING TECHNOLOGIES, which focuses on service to the machining industry; In every field where cutter technologies are needed; It operates in Izmir with its experiences, fast solutions and different perspectives.

Cooperate and coordinate with manufacturers to optimize, and “re-max" themarket share and profits for all parties.

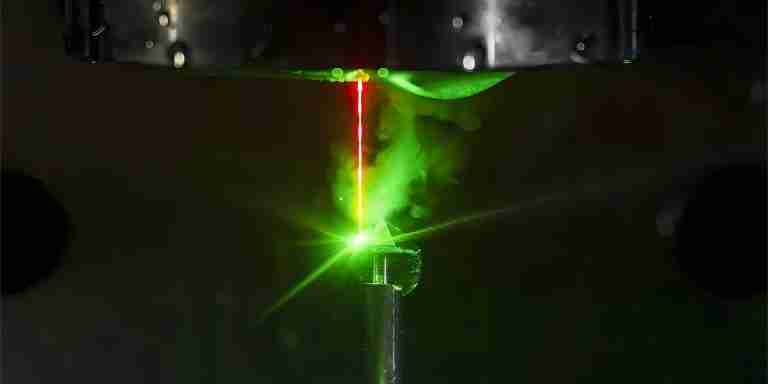

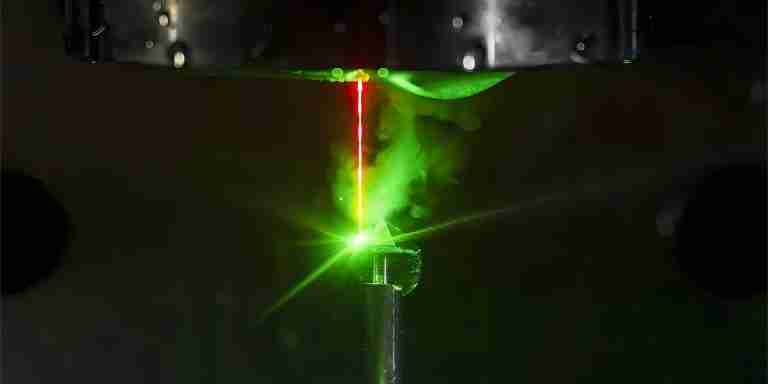

Explore ISO-certified laser systems with 0.005μm precision, 2200W/mK thermal management, and FDA-compliant diamond optics. Download technical white papers on 5-axis water-guided laser machining.

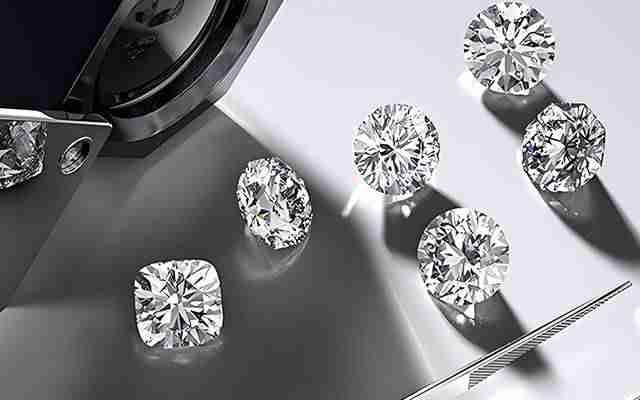

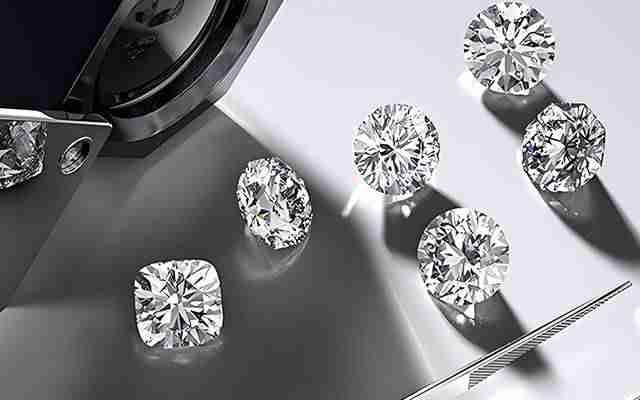

High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). These synthesis techniques create materials with identical chemical and physical properties to natural diamonds but through fundamentally different technical processes.

Chemical Vapor Deposition (CVD) has revolutionized diamond manufacturing, enabling the production of high-quality synthetic diamonds with precisely controlled properties for industrial applications. Unlike natural diamonds formed over millions of years under extreme geological conditions, CVD diamonds are created in controlled…

For specialized applications requiring expert guidance, explore OPMT's 5-axis vertical machining centers or learn more about the company's comprehensive range of laser processing solutions.

Achieve 0.003mm precision with OPMT's 5-axis laser technology for complex jewelry designs. Process diamonds 3x faster than traditional methods with superior finish quality. Transform your manufacturing capabilities today.

Environmental Challenges in Traditional Diamond Processing Diamond tool manufacturing has long relied on processes that pose significant environmental hazards. Traditional methods like electrical discharge machining (EDM) and chemical etching generate substantial toxic waste, creating environmental compliance challenges for manufacturers in…

Have you witnessed how dramatically the synthetic diamond industry has transformed in recent years? Lab-grown diamonds, produced through High-Pressure High-Temperature (HPHT) and Chemical Vapor Deposition (CVD) methods, have revolutionized the diamond market with their sustainable production and identical physical properties to natural diamonds.

From April 21-26, 2025, the 19th China International Machine Tool Exhibition (CIMT2025), one of the four major international machine tool exhibitions, grandly opened.

Compare OPMT laser systems to traditional EDM for diamond processing: 53% lower costs, 3x faster production, zero chemical waste, and superior edge quality. Find the ideal diamond machining solution.

Discover how OPMT's 5-axis CNC laser systems achieve ±0.003mm precision for lab-grown diamonds, reducing processing time by 66% and costs by 50% compared to traditional EDM methods.

Please fill in your contact information to download the PDF.