Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

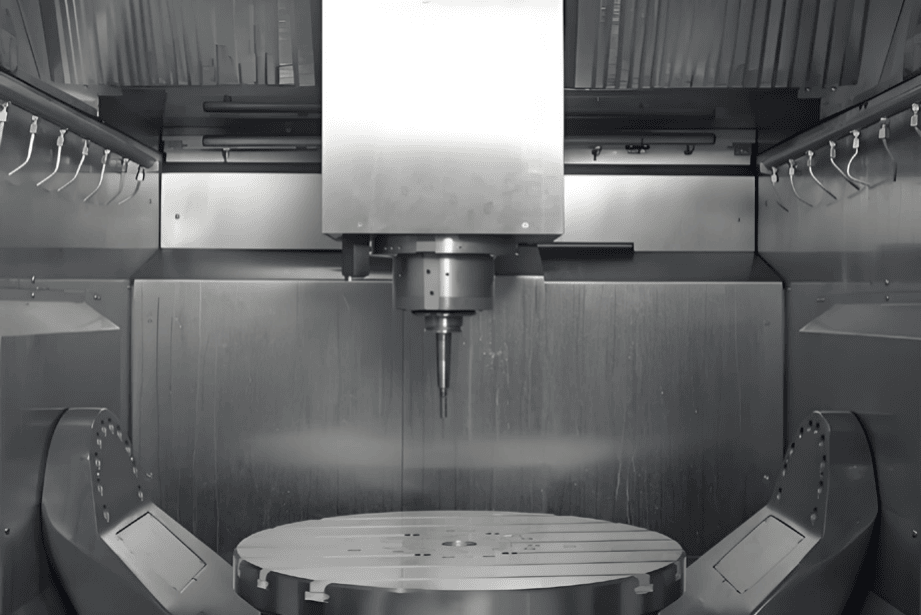

Automotive laser cutting solutions for engine components and body structure components mass production have fundamentally transformed modern vehicle manufacturing processes. Why are traditional machining methods struggling to meet the demands of today’s automotive industry? The answer lies in the precision requirements and material complexity of modern vehicles, particularly electric vehicles and lightweight components. OPMT Laser, as a leading provider of innovative CNC systems and laser processing solutions, has developed cutting-edge technology that addresses these challenges through advanced five-axis laser machining centers and intelligent processing systems.

The global automotive laser processing market has experienced unprecedented growth, reaching $4.2 billion in 2024 and projected to exceed $5.8 billion by 2025. This expansion is primarily driven by the increasing adoption of electric vehicles, stringent emission regulations, and the automotive industry’s shift toward lightweight materials. Traditional mechanical processing methods often fail when dealing with superhard materials like PCD (Polycrystalline Diamond), CBN (Cubic Boron Nitride), and advanced ceramic composites that are essential for modern engine components and body structures.

Engine component manufacturing represents one of the most demanding applications in automotive laser processing. Mass production of engine parts requires exceptional precision, particularly for components like cylinder heads, crankcase structures, and transmission housings where tolerances of ±0.003mm are standard requirements. OPMT Laser’s Light 5X 60V Vertical 5-Axis Laser Machining Center delivers this precision through advanced laser technology and sophisticated control systems.

The technical specifications achieved in real-world applications demonstrate remarkable capabilities. Processing accuracy reaches 0.003mm with positioning accuracy of 0.005mm across XYZ axes and repeat positioning accuracy of 0.003mm. The system’s laser power ranges from 100W with 1ns pulse width, enabling precise material removal while maintaining surface integrity. The workbench can handle components up to 500×500mm with a load capacity of 300kg, making it suitable for various engine component sizes.

A significant breakthrough in engine manufacturing efficiency has been achieved through OPMT Laser’s implementation at major automotive facilities. The automobile step forming milling cutter processing case study reveals processing time of just 50 minutes with blade width precision of 0.2mm, relief angle of 8 degrees, and profile accuracy of 0.006mm with passivation value of 0.0043mm. This represents a 200% improvement in curved edge and straight edge processing without chips, compared to traditional EDM methods that often result in chips and cracks at cutting edges.

Body structure components mass production faces unique challenges due to the automotive industry’s transition to lightweight materials and complex geometries. High-strength steel plates, aluminum alloys, and carbon fiber composites require specialized laser processing techniques that maintain material properties while achieving precise dimensional control. The integration of hot forming technology, where steel plates are heated to 900-950°C and rapidly cooled, creates materials with strength levels of 1000-2000 MPa that traditional tooling cannot effectively process.

OPMT Laser’s Micro3D L570V Five-Axis Femtosecond Laser Machining Center addresses these challenges through advanced five-axis linkage technology. The system achieves XYZ positioning accuracy of 0.004mm with repeat positioning accuracy of 0.003mm, while handling workpieces up to 700×600×500mm. The femtosecond laser technology with pulse widths as short as 400fs enables “cold processing” that eliminates heat-affected zones, crucial for maintaining the integrity of advanced materials.

Real-world implementation data from automotive manufacturing facilities demonstrates the effectiveness of three-dimensional five-axis laser cutting technology. Material utilization rates have improved from traditional methods’ 73% to an impressive 94%, while processing time has been reduced by 60-70%. The flexibility of laser cutting eliminates the need for dedicated tooling, enabling rapid product changeover in less than 30 minutes and supporting mixed-line production of 8-12 different product types simultaneously.

New energy vehicle battery pack laser welding technology represents a critical application where precision directly impacts vehicle safety and performance. Battery pack structures require hermetic sealing with IP67 protection levels while maintaining electrical conductivity and thermal management properties. Traditional resistance welding methods often suffer from inconsistent contact and heat distribution, leading to reliability issues in high-voltage environments.

The laser welding process achieves complete material fusion with precise heat input control, minimizing heat-affected zones that could damage sensitive battery components. Welding parameters include laser power ranging from 1-3kW with welding speeds of 5-15m/min, achieving contact resistance below 0.1mΩ consistently. This precision level ensures optimal electrical performance and extends battery pack service life significantly compared to conventional welding methods.

Performance validation from real-world applications shows remarkable improvements in battery pack manufacturing quality. Gas-tight testing pass rates have reached 99.8%, while welding defect rates have dropped from industry averages of 3.2% to just 0.08%. The automation capabilities of laser welding systems enable 24/7 production with consistent quality, crucial for meeting the growing demand for electric vehicle batteries. Production cost per battery pack module has been reduced by 40% through improved efficiency and reduced rework rates.

Quality management systems for automotive laser cutting solutions must comply with the stringent requirements of IATF16949, the automotive industry’s quality standard. This framework ensures that every aspect of laser processing, from initial material inspection to final product delivery, meets automotive-grade quality requirements. OPMT Laser’s quality control systems integrate real-time monitoring technology with comprehensive documentation and traceability systems.

The implementation of Advanced Product Quality Planning (APQP) ensures that laser processing parameters are optimized and validated before production begins. Process capability studies demonstrate consistent Cpk values exceeding 1.67, well above the automotive industry’s minimum requirement of 1.33. Real-time monitoring systems track critical parameters including laser power stability, positioning accuracy, and temperature control with automatic adjustment capabilities responding within 0.1 seconds to parameter deviations.

Statistical analysis of quality performance data reveals the superiority of laser processing technology in automotive applications. First-pass yield rates have improved from traditional machining’s 94.2% to laser processing’s 99.1%. More importantly, dimensional consistency across continuous production runs maintains variation within ±0.001mm, a level of precision that traditional machining methods cannot achieve consistently. Customer complaint rates have decreased by 75%, while rework rates have dropped from 2.1% to 0.3%.

JIT delivery capabilities in automotive manufacturing require production systems that can rapidly respond to changing demand patterns and customer requirements. Laser processing technology’s inherent flexibility provides the ideal solution through programmable “soft tooling” that eliminates the time and cost associated with traditional tooling changes. OPMT Laser’s MT30 Seven-Axis Five-Linkage Machining Center exemplifies this flexibility with product changeover times reduced to under 30 minutes.

The flexible manufacturing capabilities extend beyond simple product switching to enable true mixed-model production. A single laser processing line can simultaneously handle 12 different product specifications without compromising production efficiency. This capability is particularly valuable in automotive manufacturing where production schedules must accommodate varying model mix requirements and customer-specific options.

Supply chain integration through intelligent scheduling systems ensures optimal production flow and delivery performance. Advanced Planning and Scheduling (APS) systems interface directly with customer ERP systems, automatically optimizing production sequences based on order priority and delivery requirements. Actual performance data demonstrates average delivery cycle reduction from industry standard 15 days to 7.5 days, with on-time delivery rates reaching 99.1%. This delivery performance improvement reduces customer inventory costs while strengthening overall supply chain competitiveness.

Return on investment calculations for automotive laser cutting systems require comprehensive analysis of both direct and indirect economic benefits. Initial investment costs typically include equipment acquisition (65-70% of total), installation and commissioning (8-12%), personnel training (3-5%), and first-year maintenance (5-8%). However, the economic benefits extend far beyond simple cost reduction to include productivity improvements, quality enhancements, and strategic competitive advantages.

Direct economic benefits demonstrate compelling investment justification through multiple performance improvements. Production efficiency increases of 50-70% enable higher throughput with existing facility footprints. Labor cost reductions of 60% result from automation capabilities and reduced manual intervention requirements. Material utilization improvements of 30-40% reduce waste costs while quality improvements eliminate 80% of rework and scrap costs.

A comprehensive case study from a mid-sized automotive components manufacturer illustrates typical ROI performance. With an initial investment of $1.2 million for a complete OPMT Laser processing solution, the facility achieved annual cost savings of $720,000 through efficiency improvements, quality enhancements, and labor reduction. The investment payback period was 20 months with a five-year net present value of $2.1 million and internal rate of return of 48.6%. Additionally, the technology advancement enabled securing new high-value contracts, increasing annual revenue by 35%.

Emerging trends in automotive laser processing for 2025 focus on artificial intelligence integration, predictive maintenance capabilities, and advanced material processing techniques. Machine learning algorithms now enable automatic parameter optimization based on historical processing data, creating truly “self-learning” manufacturing systems. OPMT Laser’s latest systems incorporate AI-driven process optimization that continuously improves performance through laser applications technology advancement.

Predictive maintenance technology significantly enhances equipment reliability and production efficiency through sensor integration and big data analytics. The system provides 72-hour advance warning of potential failures, enabling planned maintenance scheduling that minimizes unexpected downtime. Real-world implementation data shows annual downtime reduction from 180 hours to 45 hours, representing a 25% improvement in overall equipment effectiveness.

Advanced material processing capabilities address the growing demand for lightweight automotive materials including carbon fiber reinforced plastics (CFRP) and metal matrix composites. Ultrafast laser processing technology utilizing femtosecond pulse durations enables precision machining of these challenging materials without thermal damage. This capability opens new possibilities for next-generation automotive design while maintaining the precision and quality requirements essential for automotive applications.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Discover laser galvanometer technology: operating principles, closed-loop vs open-loop systems, industrial applications, and integration with 5-axis CNC platforms for precision manufacturing.

Discover how advanced vertical 5-axis CNC systems achieve ±0.001-0.005mm micron-level precision for aerospace, medical, and automotive applications in 2026.

Comprehensive guide to 5-axis laser cutting machines: technology principles, advantages over 3-axis systems, industrial applications, and specifications for precision manufacturing.

Discover how 5-axis laser engraving machines deliver micron-level precision for complex surface marking, mold texturing, and industrial component identification across aerospace, automotive, and medical sectors.

Please fill in your contact information to download the PDF.