Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

The selection of an optimal 5-axis CNC machine represents a critical strategic decision that directly impacts manufacturing precision, operational efficiency, and competitive positioning in today’s advanced production environment. Modern 5-axis machining centers achieve simultaneous movement across five axes—three linear (X, Y, Z) and two rotational (A, B, or B, C)—enabling complex geometry machining that reduces setup time by up to 65% while maintaining tolerances within ±0.003mm. This comprehensive analysis examines leading 5-axis CNC technologies, implementation strategies, and performance optimization frameworks to guide engineering professionals toward informed investment decisions that align with specific production requirements and long-term operational objectives.

5-axis CNC machining centers operate on the fundamental principle of Real-Time Tool Center Point Control (RTCP), enabling continuous tool orientation adjustments while maintaining precise cutting point positioning. This advanced control methodology allows manufacturers to machine complex surfaces, undercuts, and intricate geometries impossible with conventional 3-axis systems. The integration of linear motors in premium systems delivers exceptional dynamic response characteristics, with positioning accuracies reaching 0.005mm and repeatability within 0.003mm.

Simultaneous 5-axis processing eliminates the need for multiple setups, reducing workpiece handling errors by approximately 68% compared to traditional sequential machining approaches. Advanced systems incorporate closed-loop grating scale detection across all axes, compensating for thermal expansion and mechanical backlash to maintain consistent precision throughout extended production cycles.

The convergence of laser processing with traditional CNC machining represents a significant technological advancement, particularly evident in OPMT Laser’s Light 5X series machining centers. These hybrid laser-CNC systems achieve:

Contemporary 5-axis machining centers demonstrate varying performance characteristics based on structural design, drive systems, and control integration. The following technical comparison illustrates critical specification differences:

| Specification Parameter | Entry-Level Systems | Mid-Range Systems | Premium Systems |

|---|---|---|---|

| XYZ Positioning Accuracy | ±0.008mm | ±0.005mm | ±0.003mm |

| Rotary Axis Accuracy | ±10 arcsec | ±5 arcsec | ±3 arcsec |

| Maximum Spindle Speed | 15,000 RPM | 20,000 RPM | 40,000+ RPM |

| Rapid Traverse Rate | 25 m/min | 40 m/min | 60+ m/min |

| Workpiece Capacity | 100kg | 300kg | 800kg+ |

| Thermal Compensation | Basic | Advanced | Real-time Multi-point |

| Tool Change Time | 8-12 seconds | 4-6 seconds | 2-4 seconds |

Modern 5-axis CNC systems utilize sophisticated CNC platforms incorporating adaptive machining algorithms that automatically adjust cutting parameters based on real-time sensor feedback. OPMT Laser’s implementation of NUM universal CNC systems provides up to 32 axes/spindles per NCK (Numerical Control Kernel), enabling complex multi-tasking operations with seamless RTCP compatibility.

GTR software integration facilitates direct EDM-to-laser process migration, reducing programming complexity by 75% while maintaining full 3D simulation capabilities. This user-friendly approach significantly reduces operator training requirements when transitioning from conventional machining processes to advanced 5-axis operations.

Case Study 1: PCD Milling Cutter Production

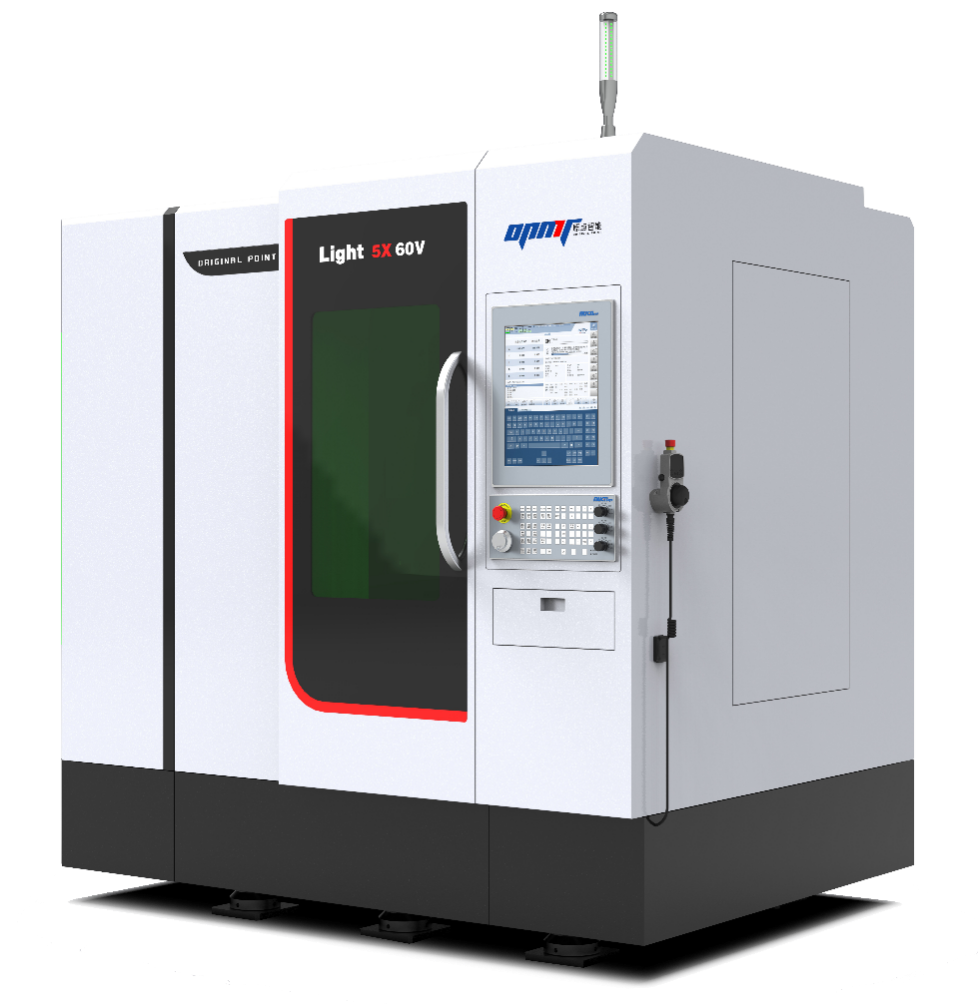

OPMT Laser’s Light 5X 60V system demonstrated exceptional performance in automotive cutting tool manufacturing, processing complex step-forming milling cutters with the following measurable outcomes:

This application showcased the system’s capability to machine PCD (Polycrystalline Diamond), CBN (Cubic Boron Nitride), and CVD (Chemical Vapor Deposition) materials essential for high-performance automotive components including engine blocks, transmission housings, and brake system components.

Implementation Challenge Resolution: Traditional EDM processing of large-particle polycrystalline diamond frequently resulted in wire skipping due to conductivity variations. The laser-based approach eliminated this limitation while achieving superior edge quality without micro-fracturing or thermal damage.

Case Study 2: Monocrystalline Diamond Blade Processing

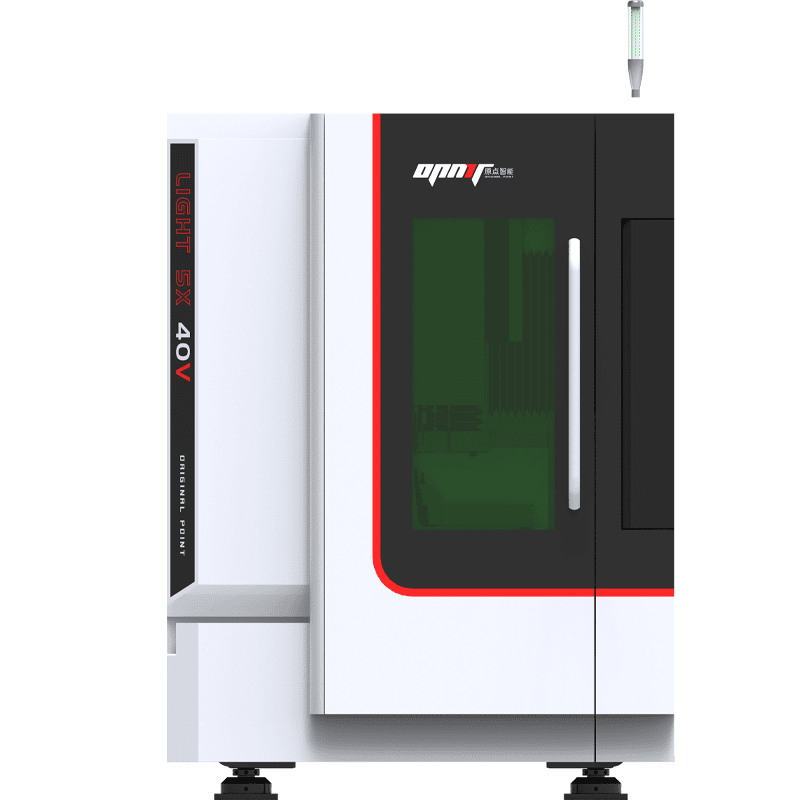

In electronics manufacturing applications, OPMT’s Light 5X 40V system processed precision cutting tools for mobile device component manufacturing:

The system’s 120° B-axis swing capability enabled complete tool geometry machining in a single setup, critical for maintaining tight tolerances on miniaturized electronic components.

Facility Requirements Analysis

Successful 5-axis CNC implementation requires comprehensive infrastructure evaluation:

Workflow Integration Planning

Optimal 5-axis implementation requires systematic approach to existing production integration:

Operator Skill Development

OPMT Laser provides comprehensive training programs covering:

Thermal Management Systems

Premium 5-axis CNC machines incorporate sophisticated thermal compensation algorithms that continuously monitor and adjust for dimensional changes. Key optimization parameters include:

Toolpath Optimization

Advanced CAM programming strategies maximize 5-axis capabilities:

ISO Compliance Framework

OPMT Laser maintains comprehensive quality management systems including:

FDA Compliance Capabilities

For medical device manufacturing applications, OPMT systems meet stringent regulatory requirements:

Direct Cost Savings Quantification

5-axis CNC implementation typically generates measurable returns through:

| Benefit Category | Quantified Impact | Measurement Period |

|---|---|---|

| Setup Time Reduction | 65% average decrease | Per production batch |

| Tool Life Extension | 40-50% improvement | Monthly tool consumption |

| Scrap Rate Reduction | 30% quality improvement | Quarterly quality metrics |

| Labor Efficiency | 25% productivity gain | Annual labor cost analysis |

| Energy Consumption | 20% reduction vs. multi-setup | Monthly utility costs |

Operational Efficiency Metrics

Advanced 5-axis systems demonstrate superior performance across multiple operational parameters:

Technology Integration Benefits

Modern 5-axis systems provide strategic advantages through:

OPMT Laser Technology Excellence

As a premier manufacturer of advanced 5-axis laser machining centers, OPMT Laser demonstrates consistent innovation leadership through:

Manufacturing Excellence Standards

OPMT’s 50,000m² manufacturing facility employs 210 skilled professionals, including 7 Ph.D.s and 47 Masters-level engineers, ensuring continuous technological advancement and application development.

Market Position Comparison

Leading manufacturers demonstrate distinct technological advantages:

| Manufacturer | Key Strengths | Target Markets | Price Range |

|---|---|---|---|

| OPMT Laser | Hybrid laser-CNC integration | Medical, Electronics, Automotive | $150K-$600K |

| DMG MORI | High-speed operations | Aerospace, Automotive | $200K-$1M |

| Mazak Corporation | Multi-tasking capabilities | General Manufacturing | $150K-$800K |

| Haas Automation | Cost-effective solutions | Job Shops, Education | $80K-$400K |

| Okuma Corporation | Thermal stability | Heavy Industry, Aerospace | $120K-$700K |

High-Volume Production Environments

For automotive and consumer electronics manufacturers processing 10,000+ components annually:

Precision Medical Device Manufacturing

Medical component production demands exceptional accuracy and regulatory compliance:

Artificial Intelligence Integration

Next-generation 5-axis systems incorporate machine learning algorithms for:

Additive-Subtractive Hybrid Systems

Revolutionary manufacturing approaches combining:

Digital Twin Technology

Virtual manufacturing environments enabling:

Project Planning Excellence

Successful implementations require:

Risk Mitigation Strategies

Common implementation challenges and solutions:

The evolution of 5-axis CNC technology continues advancing manufacturing capabilities across critical industries. OPMT Laser’s comprehensive approach to precision machining solutions combines cutting-edge laser technology with proven mechanical engineering to deliver systems capable of meeting tomorrow’s manufacturing challenges while providing measurable returns on investment today.

Through systematic evaluation of technical requirements, operational objectives, and long-term strategic goals, engineering professionals can identify 5-axis CNC solutions that enhance manufacturing capabilities while delivering sustainable competitive advantages in an increasingly demanding global marketplace.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Practical guide for electronics manufacturing: sapphire cutting, stealth dicing, water‑guided laser, and micro‑drilling. Includes 5‑axis specs, process windows, and QC targets.

Expert evaluation of industrial laser marking systems covering TRUMPF, Han’s Laser, KEYENCE, IPG, and OPMT platforms. Includes technical specs, pricing, and real ROI case studies.

Discover OPMT Laser’s ISO 9001-certified femtosecond-pulse CNC systems with sub-300 fs precision, ±0.003 mm tolerance, and AI-driven process control. Learn how top ultrafast-laser partnerships deliver 95% first-pass yields and < 12-month ROI in medical and microfabrication.

Guangdong Original Point Intelligent Technology Co., Ltd. (Original Point Intelligent), established in 2015, is a National Specialized and Innovative “Little Giant” Enterprise and National Intellectual Property Advantage Enterprise. The company

Please fill in your contact information to download the PDF.