Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Most workshops discover the hard truth about CO2 lasers and glass through expensive failures—cracked sheets, shattered edges, and wasted material. The physics is unforgiving: CO2 lasers operating at 10.6μm wavelength generate thermal stress that exceeds glass fracture limits, causing catastrophic crack propagation rather than clean separation. This isn’t a matter of adjusting power settings or pulse duration. Glass’s brittle crystalline structure simply cannot accommodate the rapid thermal gradients that CO2 lasers inevitably create.

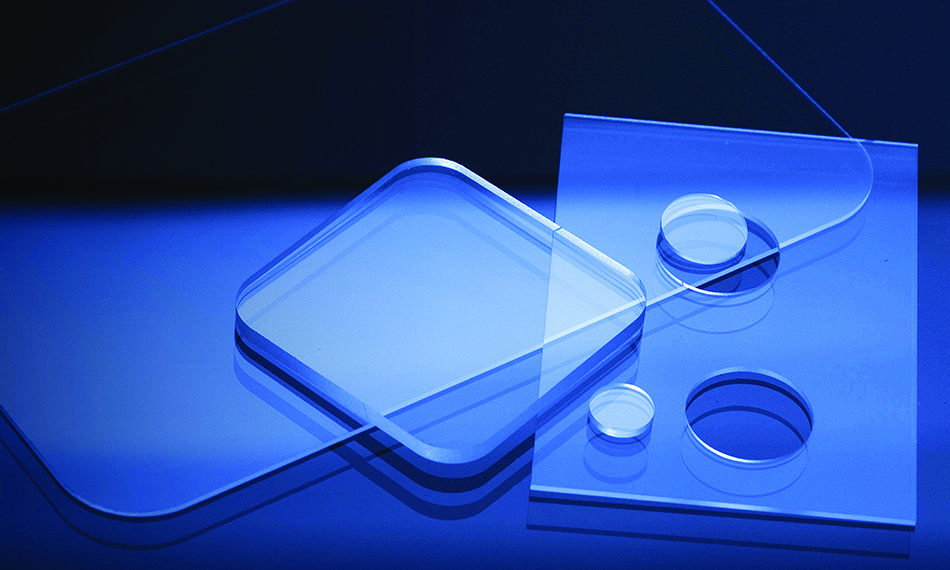

Understanding why this incompatibility exists—and knowing which laser technologies actually work for glass—prevents costly trial-and-error experimentation. UV lasers and femtosecond lasers achieve precision glass processing through fundamentally different mechanisms that eliminate thermal stress entirely. This technical distinction matters for anyone processing glass displays for smartphones, microfluidic medical devices, or precision optical components where edge quality directly affects product performance.

The failure mechanism is rooted in thermomechanics. When a CO2 laser beam strikes glass, the focal point rapidly exceeds 1500°C while surrounding material remains near ambient temperature. This creates a steep thermal gradient—essentially a temperature cliff—across microscopic distances. Glass, with its thermal expansion coefficient of 3-9 × 10⁻⁶ K⁻¹ and extremely low thermal conductivity, experiences massive internal stress as the heated zone expands against cooler regions.

Tensile stress builds perpendicular to the heating direction. Once this stress exceeds approximately 50-100 MPa—well below the levels CO2 laser heating generates—cracks initiate and propagate at near-sonic velocity. These cracks follow crystalline weak planes in the glass structure, creating the characteristic half-plane fractures that extend far beyond the intended cut path.

Material testing reveals another complication: clear glass reflects much of the 10.6μm infrared energy rather than absorbing it efficiently. This necessitates higher power levels that only exacerbate thermal stress problems. Even specialized approaches like thermal stress cleavage—using controlled heating followed by cooling jets—work only for straight cuts and cannot achieve the precision modern manufacturing demands.

CO2 lasers serve one legitimate glass application: decorative surface engraving. Operating at 30-40W power with carefully controlled parameters, the laser induces microscopic surface fracturing that creates frosted visual effects without cutting through the substrate. This technique finds use in awards, bottles, and architectural glass where aesthetic marking matters more than structural modification.

The process deliberately creates controlled surface cracks at microscopic scale. Multiple shallow passes with rapid scanning patterns distribute heat more evenly, preventing the catastrophic failures that occur when attempting to cut through glass. Surface temperatures during engraving reach 500-800°C—sufficient for visible marking but below melting points.

This represents CO2 laser technology’s practical ceiling with glass. The fundamental physics cannot be engineered around. Attempting thickness penetration inevitably triggers the thermal stress cascade that ruins the workpiece.

UV lasers at 355nm wavelength process glass through photochemical rather than photothermal mechanisms. The ultraviolet photons carry 3.5 eV energy—sufficient to directly break silicon-oxygen bonds in glass molecular structure without generating substantial heat. This “cold ablation” process eliminates thermal stress as the cutting mechanism, preventing crack formation entirely.

The physics changes fundamentally at UV wavelengths. Rather than melting and vaporizing material through heat accumulation, UV photons excite electrons to energy states where molecular bonds dissociate. Material removal occurs at the molecular level with heat-affected zones measuring under 20 micrometers. This precision enables intricate pattern cutting in soda lime, borosilicate, and specialty optical glasses while preserving structural integrity at cut edges.

OPMT’s testing with UV laser systems processing glass substrates demonstrates material removal rates of 0.1-0.3mm per pass. Multiple passes achieve through-cutting of sheets up to 2-3mm thickness with edge quality superior to mechanical scoring. Edge chipping typically measures under 5 micrometers with zero micro-crack formation—critical metrics for applications like smartphone cover glass where edge strength under impact determines device durability.

The process proves particularly valuable for soda lime glass, the most common commercial glass type. As detailed in OPMT’s comprehensive glass processing guide, soda lime glass responds well to UV laser processing while retaining the ability to undergo post-processing tempering for enhanced thermal resistance. This combination of precision cutting and subsequent strengthening opens applications in display manufacturing, architectural glass, and consumer electronics.

Femtosecond lasers deliver pulses lasting one quadrillionth of a second (10⁻¹⁵ s)—a duration so brief that thermal diffusion cannot occur during the pulse. This enables material removal through photodisruption: intense electromagnetic fields strip electrons from glass molecules, creating plasma that expands as a shockwave, mechanically removing material at the focal volume. The entire process completes before thermal energy conducts to surrounding material, creating heat-affected zones measuring less than 1 micrometer.

OPMT Laser’s Micro3D L530V five-axis femtosecond laser machining center exemplifies this technology’s industrial implementation. The system achieves positioning accuracy of ±0.003mm with repeatability of ±0.002mm. Linear motor drive on all three axes combined with high-precision torque motors on rotational axes enables processing of complex three-dimensional glass geometries including curved surfaces, beveled edges, and compound angles that mechanical methods cannot achieve.

Real-world performance data from automotive tool manufacturing demonstrates the practical advantages. PCD contour cutters processed on OPMT’s femtosecond systems achieve processing accuracy of 0.005mm with blade widths of 0.2mm and relief angles up to 15 degrees. Surface finish measures below 0.1μm roughness, with absolutely no chipping or cracking at magnifications exceeding 200×. These results persist across production volumes, with documented consistency showing tolerance variations stabilized within 0.001mm.

The technology extends beyond simple cutting. OPMT’s Micro3D L570V mold texturing system uses femtosecond laser technology to create surface microstructures with dimensional precision of 0.01mm. Unlike traditional chemical texturing limited to 3-5 texture layers, the femtosecond system processes 30-50 distinct layers while maintaining perfect control over three-dimensional geometry. This capability proves transformative for applications requiring functional surface modifications—anti-glare treatments, optical diffusion patterns, and tactile surface features in consumer electronics.

Processing parameters demonstrate the technology’s versatility. OPMT’s femtosecond laser systems handle materials from thin glass substrates under 0.5mm—notoriously fragile—up to 25mm thickness depending on composition. The LP550V five-axis ultrafast laser rotary cutting machine drills holes from 0.1-1mm diameter with 2μm precision and aspect ratios reaching 30:1, capabilities impossible with conventional drilling or CO2 laser technology.

| Processing Method | Wavelength | Glass Cutting Capability | Heat-Affected Zone | Typical Edge Quality | Maximum Practical Thickness | Primary Applications | Relative Operating Cost |

|---|---|---|---|---|---|---|---|

| CO2 Laser | 10.6 μm | Surface marking only | >500 μm (causes cracking) | Poor – fractures | N/A for cutting | Decorative engraving, awards | Lowest equipment cost, not suitable for precision |

| UV Laser (355nm) | 355 nm | Clean cuts achievable | <20 μm | Excellent – minimal chipping | 0.1-3 mm | Smartphone displays, optical components, medical devices | Moderate equipment cost, efficient operation |

| Femtosecond Laser | Variable (IR) | Superior precision | <1 μm | Outstanding – zero thermal damage | 0.03-25 mm | Advanced optics, microfluidics, aerospace components | Higher equipment cost, lowest per-part cost at volume |

The data reveals an inverse relationship between wavelength and processing quality for glass. CO2’s 10.6μm infrared wavelength interacts with glass primarily through bulk heating, while UV’s 355nm enables photochemical bond breaking. Femtosecond pulses transcend wavelength limitations entirely by delivering energy faster than thermal diffusion timescales.

Power requirements follow counterintuitive patterns. CO2 systems require 50-100W but cannot achieve clean cutting. UV lasers operate at 5-20W while delivering precision cuts. OPMT’s femtosecond systems at 20W provide ultimate precision. This demonstrates that pulse duration and wavelength matter far more than raw power for glass processing applications.

Cost analysis must account for total ownership rather than just equipment acquisition. CO2 lasers represent the lowest capital investment ($ 3,000-15,000) but cannot perform precision glass work. UV laser systems cost $ 25,000-80,000 with moderate operational expenses. Femtosecond platforms like OPMT’s Micro3D series range from $150,000-500,000, yet documented case studies show 53% lower operating costs compared to conventional EDM processing for certain applications due to elimination of secondary operations.

Material composition dictates processing viability. Soda lime glass—used in approximately 90% of commercial glass applications—processes more readily than borosilicate due to lower thermal resistance. Chemically strengthened glass used in premium smartphone displays requires UV or femtosecond laser processing with precisely controlled parameters to avoid disrupting the ion-exchange layer. Optical glasses with specific refractive indices demand femtosecond precision to maintain optical properties across cut edges.

Thickness constraints become critical selection factors. Glass sheets under 0.5mm present extreme fragility that eliminates mechanical cutting options entirely. UV lasers handle this thickness range effectively for simpler geometries. Complex three-dimensional shapes in thin glass—think curved smartphone cover glass or miniature optical lenses—require femtosecond technology’s combination of precision and minimal mechanical stress.

Edge strength requirements establish minimum technology thresholds. Applications demanding edge strengths exceeding 100 MPa—such as structural glass in electronics housings or medical device windows—require UV or femtosecond processing. The microscopic surface quality these technologies produce translates directly to mechanical performance. Traditional scoring or CO2 engraving creates microscopic flaws that become crack initiation points under stress.

Production volume calculations affect economic optimization. Low-volume prototyping or custom architectural glass may justify UV laser processing despite longer cycle times. High-volume manufacturing—processing thousands of smartphone displays daily—benefits from femtosecond laser speed and reliability. OPMT’s Micro3D systems achieve processing speeds 3-5 times faster than conventional methods while maintaining superior quality, creating compelling return-on-investment at production scale.

Industry-specific considerations further refine technology selection. Medical device manufacturers face stringent regulatory requirements for biocompatibility and sterility. The pristine surface quality femtosecond lasers produce eliminates concerns about surface contamination or altered material properties. Electronics manufacturers prioritize throughput and dimensional consistency; OPMT’s systems demonstrate repeatability within ±0.002mm across millions of cycles. Optical component producers require surface finishes approaching polish quality; femtosecond processing delivers roughness below 0.1μm without secondary operations.

OPMT Laser has developed comprehensive femtosecond laser machining centers that address the complete manufacturing workflow. The Micro3D L530V integrates a 20W femtosecond laser with OPMT’s proprietary iMTOS CNC control system featuring 13-axis sub-nanometer linkage interpolation. This sophisticated control architecture enables complex three-dimensional path planning while maintaining micron-level accuracy throughout extended production runs.

The system architecture reflects real manufacturing requirements. Natural marble machine beds provide thermal stability and vibration damping impossible with welded steel structures. Linear motor drives on all axes eliminate mechanical transmission errors while achieving rapid traverse speeds of 20-30 m/min. Full closed-loop grating scale feedback ensures positioning accuracy remains stable regardless of thermal variations or mechanical wear.

Process monitoring capabilities distinguish industrial systems from laboratory equipment. High-definition CCD cameras provide real-time workpiece alignment with automatic edge detection. High-precision probes enable in-process dimensional verification, catching quality deviations before completing expensive multi-hour processing runs. The integrated dust collection system maintains optical component cleanliness—critical for consistent laser performance—while meeting environmental regulations.

OPMT’s mold texturing applications demonstrate femtosecond technology’s expanded capabilities. The Micro3D L570V processes complex curved surfaces including spherical and aspherical geometries with texture precision of 0.01mm. Automotive manufacturers use this technology to create functional surface patterns on injection molds—honeycomb structures, geometric patterns, and micro-dimensional features—that traditional chemical etching cannot achieve. The environmental benefits prove substantial: elimination of strong acid baths, zero chemical waste generation, and significant reductions in processing time from days to hours for complex textures.

Software integration reduces the traditional complexity barrier for femtosecond laser operation. OPMT’s self-developed CAM software imports 3D models directly, automatically generating optimized five-axis toolpaths. The system includes collision detection and motion simulation, preventing expensive crashes during initial program development. This automation makes advanced femtosecond technology accessible to conventional manufacturing teams without requiring PhD-level laser physics expertise.

The convergence of laser technology and artificial intelligence is creating new possibilities. OPMT’s systems already incorporate algorithm-driven path optimization that adapts to material variations in real-time. Future developments will likely include predictive maintenance systems that use vibration analysis and thermal imaging to schedule component replacement before failures occur, further improving production uptime beyond current 95% availability levels.

Material science advances expand processing possibilities. New glass compositions engineered for laser processability—incorporating specific dopants that enhance photochemical absorption at UV wavelengths or optimize thermal properties for femtosecond interaction—will emerge from research collaborations between glass manufacturers and laser technology companies like OPMT. These engineered materials could enable even thinner substrates and more complex geometries than current technology allows.

The broader laser processing landscape continues evolving. Comparing nanosecond, picosecond, and femtosecond laser technologies reveals ongoing refinement across the spectrum of pulse durations and wavelengths. Each advance in laser physics, control systems, and beam delivery optics expands manufacturing capabilities, enabling products that weren’t economically viable just years earlier.

Can a CO2 laser cut through glass without cracking?

No. CO2 lasers cannot cut through glass without inducing catastrophic thermal stress cracking. The 10.6μm wavelength generates localized heating that exceeds glass fracture thresholds regardless of power settings or pulse parameters. The fundamental physics of thermal expansion in brittle materials makes clean CO2 laser glass cutting impossible.

What causes glass to crack when exposed to CO2 laser energy?

Rapid localized heating creates steep thermal gradients across microscopic distances. Glass with high thermal expansion coefficients (3-9 × 10⁻⁶ K⁻¹) and extremely low thermal conductivity experiences tensile stress exceeding 200-400 MPa—far beyond the 50-100 MPa fracture threshold. Cracks propagate at near-sonic velocity following crystalline weak planes in the glass structure.

Are there any glass processing applications where CO2 lasers work effectively?

Yes—surface engraving for decorative purposes. Operating at 30-40W with controlled parameters, CO2 lasers create frosted visual effects through microscopic surface fracturing without cutting through the substrate. This technique suits awards, bottles, and architectural glass where aesthetic marking matters more than structural modification.

How do UV lasers differ from CO2 lasers for glass processing?

UV lasers at 355nm wavelength use photochemical ablation—direct bond breaking at the molecular level—rather than thermal melting. Each 3.5 eV photon has sufficient energy to dissociate silicon-oxygen bonds without generating substantial heat. This creates heat-affected zones under 20 micrometers versus 500+ micrometers with CO2 lasers, preventing crack formation entirely.

What makes femtosecond lasers superior for precision glass applications?

Femtosecond pulses (10⁻¹⁵ seconds duration) complete material removal before thermal diffusion occurs. Material is removed through photodisruption—plasma formation and shockwave expansion—with heat-affected zones below 1 micrometer. OPMT’s Micro3D systems demonstrate positioning accuracy of ±0.003mm with repeatability of ±0.002mm, achieving surface finishes below 0.1μm roughness without secondary operations.

Can borosilicate glass be laser cut effectively?

Yes, but only with UV or femtosecond lasers. Borosilicate’s high thermal resistance and low thermal expansion coefficient (3.3 × 10⁻⁶ K⁻¹) make it more suitable than soda lime glass for laser processing despite requiring higher energy densities. CO2 lasers fail on borosilicate even more catastrophically than on soda lime due to poor infrared absorption.

What thickness range can femtosecond lasers process in glass?

OPMT’s femtosecond laser systems handle glass from ultra-thin substrates under 0.5mm up to 25mm depending on composition and application requirements. The LP550V processes fragile thin glass with zero mechanical stress while maintaining dimensional accuracy, and can drill through thicker glass with aspect ratios reaching 30:1.

Which industries require precision laser glass cutting technology?

Medical device manufacturing for biocompatible components, consumer electronics (3C industry) for display glass and housings, optical component production for lenses and sensors, automotive displays requiring curved glass, and luxury goods with functional surface texturing all depend on precision laser glass processing. Each industry prioritizes different aspects—medical requires pristine surface quality, electronics demands throughput and consistency, optics needs sub-micron precision.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.