Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

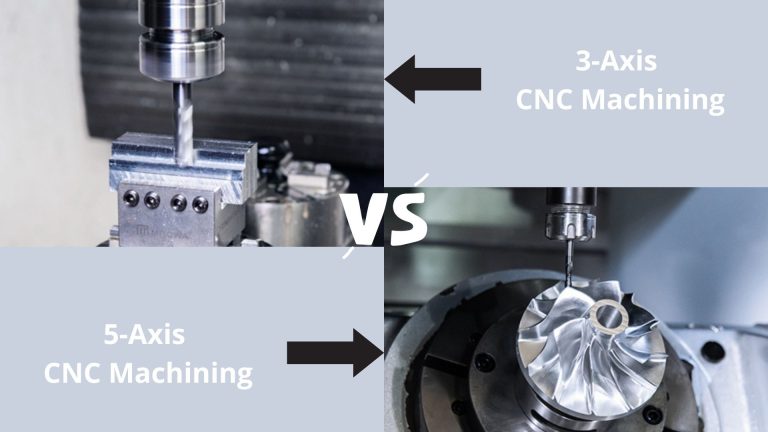

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT's proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Uncover the top 10 laser cutting manufacturers for 2025, featuring trusted brands, competitive pricing, and innovative technology that can transform your production process.

Expert guide to lab diamond machine technology covering HPHT and CVD synthesis equipment, laser processing systems, cost analysis, and supplier selection for 2026.

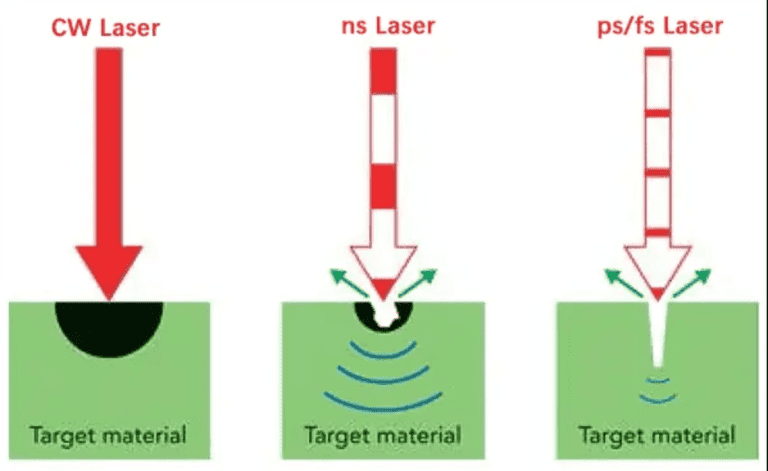

Compare picosecond vs nanosecond laser systems for industrial manufacturing. HAZ data, processing speeds, cost analysis, and application criteria from OPMT's deployed systems.

PCD laser cutting machines deliver 0.003mm accuracy and 3x faster processing than EDM. Complete technical guide to polycrystalline diamond tool manufacturing for aerospace and automotive industries.

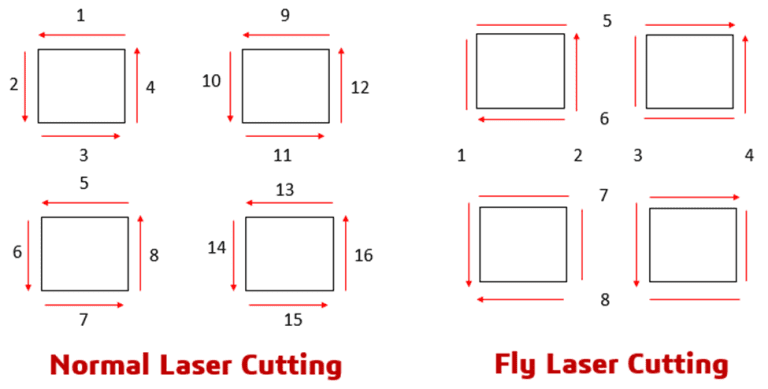

Fly cut laser technology reduces cycle time by 30-50% through continuous motion path optimization. Learn mechanics, applications, and OPMT equipment specifications for precision manufacturing.

Factory evaluation frameworks for laser cutting equipment procurement. Infrastructure assessment, quality systems analysis, and total cost of ownership calculations based on 30+ facility audits.

Compare top 5-axis CNC machine manufacturers including DMG MORI, Mazak, and OPMT Laser. Technical specs, pricing tiers, and application guide for aerospace, automotive, and medical device industries.

Discover laser galvanometer technology: operating principles, closed-loop vs open-loop systems, industrial applications, and integration with 5-axis CNC platforms for precision manufacturing.

Please fill in your contact information to download the PDF.