Vereinbaren Sie einen Besuch

Egal ob Sie eine allgemeine Beratung oder spezifische Unterstützung benötigen, wir helfen Ihnen gerne weiter.

Egal ob Sie eine allgemeine Beratung oder spezifische Unterstützung benötigen, wir helfen Ihnen gerne weiter.

Alle News

Aktie

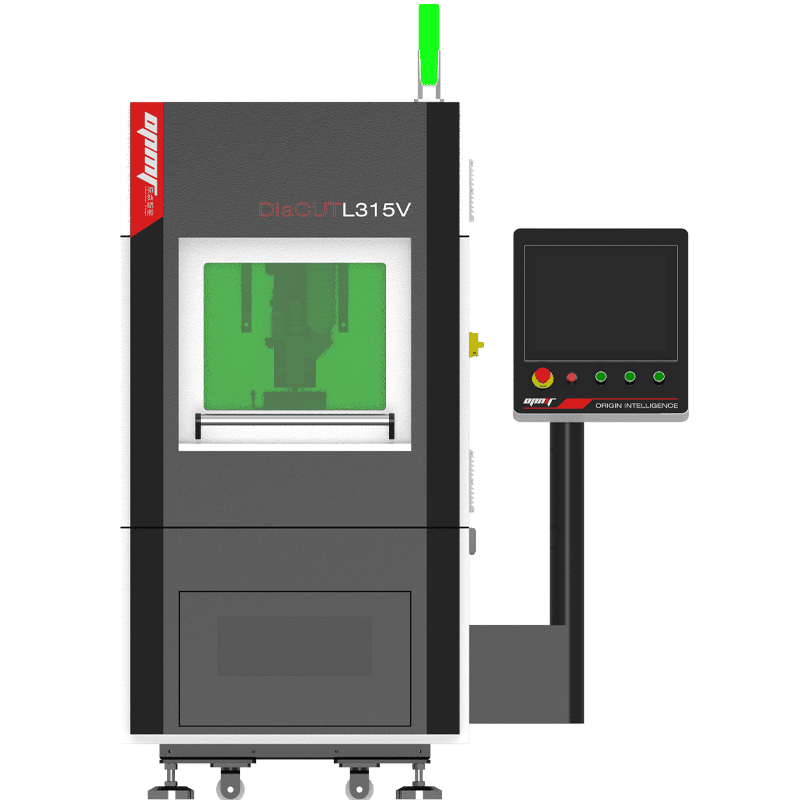

Die Fertigung von Präzisionsbauteilen aus superharten Werkstoffen stellte traditionelle Bearbeitungsverfahren bisher vor große Herausforderungen. Die Entwicklung des 5-Achs-Diamantdrehens in Kombination mit fortschrittlicher Lasertechnologie hat die Ultrapräzisionsfertigung von polykristallinem Diamant (PCD), kubischem Bornitrid (CBN) und mittels chemischer Gasphasenabscheidung (CVD) hergestellten Diamantbauteilen revolutioniert. Dieser Durchbruch kombiniert die simultane 5-Achs-Bewegungssteuerung mit Femtosekunden-Laserablation und erreicht eine Positioniergenauigkeit von 0,003 mm bei gleichzeitiger Oberflächenrauheit unter 0,1 μm Ra – Spezifikationen, die mit konventionellen Verfahren wie Funkenerosion (EDM) oder Schleifen bisher nicht erreichbar waren.

Die Branchen Luft- und Raumfahrt, Medizintechnik, Automobilindustrie und Präzisionswerkzeugbau setzen zunehmend auf 5-Achs-Diamantdrehmaschinen zur Fertigung komplexer Geometrien aus superharten Werkstoffen. Diese Anwendungen erfordern nicht nur höchste Maßgenauigkeit, sondern auch die Möglichkeit, nichtleitende Materialien zu bearbeiten, die bei herkömmlichen EDM-Systemen zu Drahtsprüngen führen. 5-Achs-Laserbearbeitungszentren Ausgestattet mit RTCP-Technologie (Rotation Tool Center Point) und ultraschnellen Lasersystemen ermöglichen sie 200% schnellere Bearbeitungsgeschwindigkeiten bei 50% geringeren Stückkosten im Vergleich zu herkömmlichen Methoden und eliminieren gleichzeitig das Ausbrechen von Kanten und das Reißen des Materials, die bei traditionellen Verfahren häufig auftreten.

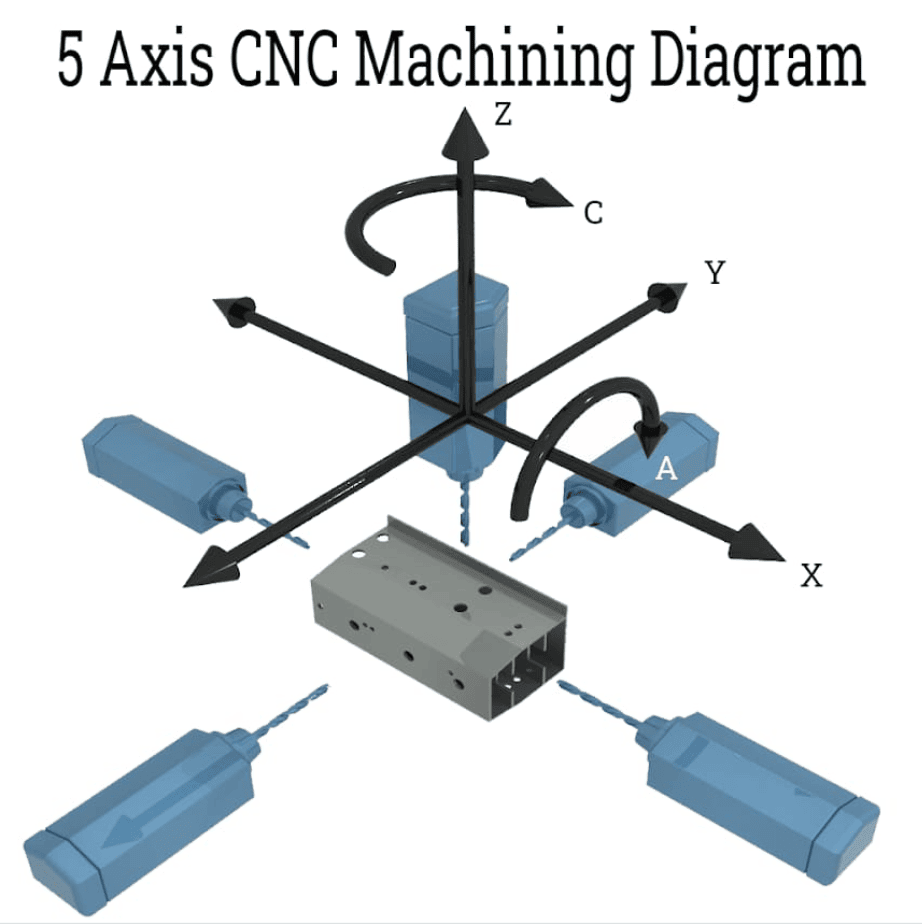

Das 5-Achs-Diamantdrehen ist ein fortschrittliches Fertigungsverfahren, das die simultane 5-Achs-Bewegungssteuerung mit hochpräziser Laserablation kombiniert, um superharte Materialien mit außergewöhnlicher Genauigkeit zu bearbeiten. Im Gegensatz zum herkömmlichen Diamantdrehen, das auf rotationssymmetrische Teile beschränkt ist, ermöglicht diese Technologie die Herstellung komplexer, nicht rotationssymmetrischer Oberflächen durch die Integration von drei linearen Achsen (X, Y, Z) mit zwei Rotationsachsen (typischerweise B- und C-Achse).

Der grundlegende Unterschied zwischen dem traditionellen Einpunkt-Diamantdrehen (SPDT) und der modernen 5-Achs-Laser-Diamantbearbeitung liegt im Bearbeitungsmechanismus und den geometrischen Möglichkeiten. Beim traditionellen SPDT wird ein diamantbestücktes Schneidwerkzeug verwendet, das das Werkstück physisch berührt. Dadurch ist die Anwendung auf weichere Materialien und symmetrische Geometrien beschränkt. Im Gegensatz dazu nutzt das 5-Achs-Laser-Diamantdrehen fokussierte Laserenergie, um Material durch thermische oder photochemische Prozesse abzutragen. Dies vermeidet Werkzeugverschleiß und ermöglicht die Bearbeitung komplexer dreidimensionaler Konturen, die mit kontaktbasierten Verfahren nicht realisierbar sind.

Die Technologie des Rotationswerkzeug-Zentrumspunkts (RTCP) stellt einen entscheidenden Fortschritt dar, der die präzise Positionierung des Werkzeugs relativ zum Werkstück während komplexer Mehrachsenbewegungen gewährleistet. Diese Fähigkeit stellt sicher, dass der Laserfokuspunkt unabhängig von den Positionen der Rotationsachsen konstant bleibt, was für die Herstellung der filigranen Facetten und komplexen Freiwinkel, die bei Präzisionsschneidwerkzeugen erforderlich sind, unerlässlich ist. 5-Achs-CNC-Bearbeitungszentren Ausgestattet mit RTCP-Funktionalität können simultane Fünf-Achsen-Bewegungen ausgeführt werden, wobei die Positioniergenauigkeit innerhalb von 5 Mikrometern gehalten wird.

Der Schwenkwinkel der B-Achse, typischerweise zwischen 110° und 120°, ermöglicht die Bearbeitung steiler Wandwinkel und Hinterschnitte, die mit herkömmlichen Drei-Achs-Konfigurationen nicht realisierbar wären. Diese Rotationsfähigkeit, kombiniert mit der Rotation der C-Achse (typischerweise 360° kontinuierlich), erlaubt es Herstellern, komplette Werkzeuggeometrien in einer einzigen Aufspannung zu bearbeiten und so Positionierungsfehler zu vermeiden, die sich über mehrere Bearbeitungsgänge hinweg summieren.

Die Luft- und Raumfahrtindustrie nutzt das 5-Achs-Diamantdrehen zur Herstellung asphärischer Linsen, Freiformspiegel und präziser Infrarotoptiken, bei denen die Oberflächenformfehler unterhalb von λ/10 (Spitze-Tal) liegen müssen. Die Medizintechnikbranche ist auf diese Technologie angewiesen, um chirurgische Schneidwerkzeuge, mikrofluidische Bauteile und Oberflächen implantierbarer Komponenten herzustellen, die biokompatible Oberflächen mit Rauheitsspezifikationen im Nanometerbereich erfordern.

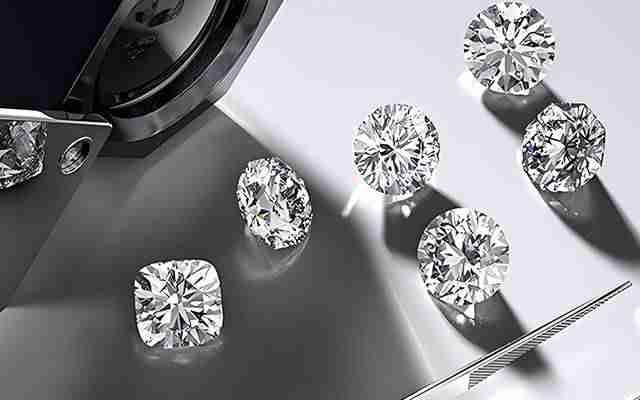

Hersteller von Präzisionsschneidwerkzeugen stellen das größte Anwendungssegment dar und verarbeiten PKD- und CBN-Wendeschneidplatten für die Bearbeitung von Automobilmotoren, die Endbearbeitung von Getriebekomponenten und die Zerspanung von Verbundwerkstoffen. Die Möglichkeit, komplexe Spanbrechergeometrien, negative Fasen und kontrollierte Schneidkantenpräparationen mit einer Präzision von 0,001 mm zu erzeugen, wirkt sich unmittelbar auf die Werkzeugstandzeit und die Bearbeitungsleistung in der Serienfertigung aus. Verarbeitung von im Labor gezüchteten Diamanten Anlagen nutzen diese Technologie, um eine Reduzierung der Bearbeitungszeit um 66% zu erreichen und gleichzeitig Oberflächen in Edelsteinqualität zu erhalten.

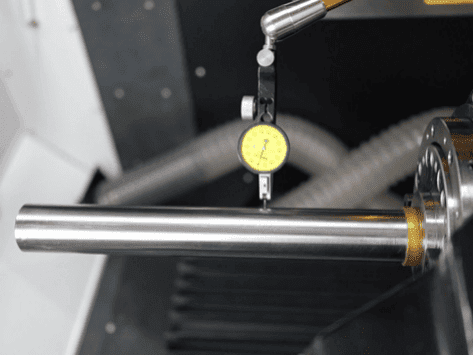

Moderne Fünf-Achs-Bearbeitungssysteme für das Diamantdrehen erreichen eine Positioniergenauigkeit von ≤ 0,005 mm (5 Mikrometer) entlang der linearen Achsen, mit Wiederholgenauigkeiten von bis zu 0,003 mm. Diese Präzisionswerte, die durch Laserinterferometrie und Kugelstabprüfung verifiziert wurden, ermöglichen es Herstellern, enge Toleranzen über lange Produktionsläufe hinweg ohne Abweichungen oder Qualitätsverluste einzuhalten.

Die in die X-, Y- und Z-Achse integrierten Linearmotorantriebe bieten gegenüber herkömmlichen Kugelgewindetrieben oder Zahnstangenantrieben mehrere Vorteile. Linearmotoren eliminieren mechanisches Spiel vollständig und reagieren verzögerungsfrei auf Richtungsänderungen. Dies ist entscheidend für die Bahngenauigkeit bei komplexen Werkzeugbahnen. In Kombination mit hochauflösenden Linear-Encodern, die eine Positionsrückmeldung im Submikrometerbereich ermöglichen, erreichen diese Systeme dynamische Steifigkeitswerte von über 100 N/µm – unerlässlich zur Unterdrückung vibrationsbedingter Oberflächenartefakte.

Der Schwenkwinkel der B-Achse bestimmt direkt den Bereich der Geometrien, die ohne Werkstückneupositionierung bearbeitet werden können. Systeme mit 120° B-Achsen-Rotation ermöglichen die Bearbeitung von Werkzeugen mit steilen Freiwinkeln bis zu 25° und decken damit das gesamte Spektrum der in der Luft- und Raumfahrt sowie der Automobilindustrie verwendeten Schnittgeometrien ab. Die Nenndrehzahl der B-Achse von 100–200 U/min gewährleistet ein ausgewogenes Verhältnis zwischen Durchsatz und dynamischer Positioniergenauigkeit, da höhere Drehzahlen zu Fliehkräften führen können, die die Präzision beeinträchtigen.

Die Spezifikationen der C-Achse umfassen typischerweise eine kontinuierliche 360°-Drehung mit Nenndrehzahlen von 200–300 U/min. Dies ermöglicht die spiralförmige Interpolation zur Herstellung von Spiralnuten und komplexen Spanbrecherstrukturen. Die maximale Tragfähigkeit des C-Achsen-Werkbanksystems – von 10 kg bei kompakten Systemen bis zu 40 kg bei produktionsorientierten Konfigurationen – bestimmt den Größenbereich der bearbeitbaren Werkstücke bei Einhaltung der vorgegebenen Genauigkeitsanforderungen.

Das laserbasierte Diamantdrehen erreicht Bearbeitungsgeschwindigkeiten von 3,0 mm/min bei der Materialabtragung und stellt damit eine Verbesserung um den Faktor 1001 gegenüber herkömmlichen EDM-Verfahren dar, die auf 1,5 mm/min begrenzt sind. Dieser Geschwindigkeitsvorteil verstärkt sich noch dadurch, dass die Laserbearbeitung die beim EDM-Verfahren erforderlichen Ausfallzeiten durch Drahteinfädeln und Elektrodenverschleißkompensationszyklen eliminiert. Bei einem typischen Sägeblatt mit 500 mm Durchmesser ist die Bearbeitung mit Laser in 8 Stunden abgeschlossen, im Vergleich zu 24 Stunden beim EDM-Verfahren – die Produktionskapazität wird somit effektiv verdreifacht.

Die erzielten Ergebnisse hinsichtlich der Oberflächenrauheit zeichnen fortschrittliche Technologien aus Femtosekundenlasersysteme Durch die Verwendung von Lasern mit Nanosekunden-Pulsdauer werden Oberflächenrauheitswerte von ≤ 0,1 μm Ra auf polykristallinen Diamantmaterialien erzielt. Führende Systeme erreichen sogar 0,08 μm Ra auf Präzisionsbauteilen. Diese Oberflächen erreichen eine Qualität, die mit geschliffenen und polierten Oberflächen vergleichbar ist, und eliminieren gleichzeitig die üblicherweise erforderlichen, zeitaufwändigen Nachbearbeitungsschritte.

Die Formgenauigkeitsvorgaben für Diamantdrehbearbeitungen zielen typischerweise auf eine Abweichung von besser als λ/10 (ca. 60 nm im sichtbaren Wellenlängenbereich) ab, um die Herstellung optisch hochwertiger Oberflächen zu ermöglichen. Diese präzise Formkontrolle erfordert neben exakten Bewegungssystemen auch Strategien zum Wärmemanagement, die die Dimensionsstabilität während längerer Bearbeitungszyklen gewährleisten.

Die Bearbeitung von polykristallinem Diamant (PKD) ist der Haupttreiber für die Anwendung fortschrittlicher 5-Achs-Laserdrehtechnologie. PKD-Werkstoffe, bestehend aus unter hohem Druck und hoher Temperatur gesinterten Diamantpartikeln, weisen Härtewerte von über 8000 HV auf. Dadurch eignen sie sich ideal zum Schneiden von Nichteisenmetallen und abrasiven Verbundwerkstoffen, sind aber mit konventionellen Methoden schwer zu bearbeiten. Das laserbasierte Diamantdrehen erreicht eine Maßstabilität von 0,003 mm bei der Bearbeitung von PKD-Schneidwerkzeugeinsätzen und ermöglicht es Herstellern, die engen Toleranzvorgaben für die Präzisionsbauteilfertigung einzuhalten.

Der entscheidende Vorteil der PKD-Bearbeitung liegt in der berührungslosen Laserablation. Herkömmliche Schleifverfahren erzeugen erhebliche Wärme und mechanische Spannungen, die zu Mikrorissen in der Diamantstruktur führen und die Werkzeugleistung beeinträchtigen können. Die Femtosekundenlaserbearbeitung hingegen entfernt Material durch Kaltablation – die Pulsdauer ist kürzer als die thermische Diffusionszeit – wodurch Wärmestau verhindert und die kristalline Integrität der Diamantmatrix erhalten bleibt.

Die chemische Gasphasenabscheidung (CVD) von Diamant stellt aufgrund seiner säulenförmigen Kornstruktur und hohen Wärmeleitfähigkeit besondere Herausforderungen an die Verarbeitung. Diese Werkstoffe finden Anwendung in Wärmeverteilern, optischen Fenstern für Hochleistungslasersysteme und Beschichtungen für Schneidwerkzeuge, wo die Eigenschaften von Einkristall- oder hochreinem polykristallinem Diamant erforderlich sind. Das 5-Achs-Diamantdrehen mit ultraschnellen Lasersystemen ermöglicht die Mikrostrukturierung von Fotolackmustern auf CVD-Diamantsubstraten bis zu einer Größe von 50 nm mit einer außergewöhnlichen Kantenschärfe, die für photonische und MEMS-Anwendungen unerlässlich ist.

Die CVD-Diamantbearbeitung profitiert erheblich von den Kaltablationseigenschaften der Femtosekundenlaserbearbeitung. Pulsdauern ≤ 400 Femtosekunden liefern Energie schneller, als die phononvermittelte Wärmediffusion erfolgen kann. Dadurch entsteht ein lokalisiertes Plasma, das Material explosionsartig abträgt, ohne eine Wärmeeinflusszone zu erzeugen. Dieser Mechanismus verhindert die Graphitisierung, die bei der konventionellen Bearbeitung von CVD-Diamant über 600 °C auftritt, und erhält die für die mechanischen und thermischen Eigenschaften essentielle sp³-gebundene Kohlenstoffstruktur.

Kubisches Bornitrid (CBN) ist nach Diamant das zweithärteste Material und daher unentbehrlich für die Bearbeitung gehärteter Stähle und Gusseisen, da PKD mit Eisenwerkstoffen chemisch reagieren würde. Die Verarbeitung von CBN-Bauteilen erfolgt mit Lasertechnologie im Vergleich zu herkömmlichen Methoden Dies zeigt deutliche Vorteile hinsichtlich Schnittkantenqualität und Wirtschaftlichkeit der Bearbeitung. Die Kaltablation durch ultraschnelle Lasersysteme erhält die außergewöhnliche Härte von CBN im gesamten Bearbeitungsbereich – ein entscheidender Faktor bei Anwendungen, bei denen die CBN-Schneidkante Temperaturen von über 1000 °C während unterbrochener Schneidvorgänge standhalten muss.

Das herkömmliche Schleifen von CBN-Werkzeugen erzeugt Temperaturen, die eine teilweise Umwandlung in hexagonales Bornitrid (h-BN) bewirken. Dieses weist jedoch nicht die Härte und Verschleißfestigkeit der kubischen Phase auf. Die Femtosekundenlaserbearbeitung hält die Spitzentemperaturen unterhalb der Phasenumwandlungsschwelle und gewährleistet so, dass Werkzeugleistung und Standzeit den Konstruktionsvorgaben entsprechen.

Großkörniger polykristalliner Diamant und bestimmte CVD-Diamantsorten weisen eine geringe elektrische Leitfähigkeit auf, wodurch sie sich nicht mittels Drahterodieren bearbeiten lassen. Bei der Bearbeitung dieser Materialien durch Drahterodieren führt die geringe Leitfähigkeit zu unregelmäßiger Funkenbildung – einem Phänomen, das als „Drahtüberspringen“ bekannt ist – was eine unregelmäßige Schnittgeometrie und häufigen Drahtbruch zur Folge hat. Das laserbasierte Diamantdrehen umgeht diese Einschränkung vollständig, da die optische Energiezufuhr keine elektrische Leitfähigkeit im Werkstückmaterial erfordert.

Das Schleifen als Alternative, das zwar nichtleitende Materialien bearbeiten kann, leidet unter hohem Werkzeugverschleiß und langen Zykluszeiten. Diamantschleifscheiben verschleißen beim Bearbeiten von PKD- oder CVD-Diamanten schnell, sodass die Abrichtintervalle nur noch Minuten statt Stunden betragen. Die Laserbearbeitung eliminiert die Kosten für Verbrauchsmaterialien vollständig und ermöglicht eine 20-mal höhere Materialabtragsrate im Vergleich zu konventionellen Schleifverfahren.

Die Kostenanalyse zeigt, dass das 5-Achs-Schneiden mit Lasertechnologie bei der Bearbeitung von superharten Werkstoffen im Vergleich zur Funkenerosion (EDM) niedrigere Stückkosten (50%) liefert. Dieser wirtschaftliche Vorteil beruht auf mehreren Faktoren: Wegfall von Elektrodenverschleiß und damit verbundenen Austauschkosten, kürzere Zykluszeiten, kein Drahtverbrauch und vereinfachte Spannvorrichtungen, die eine höhere Werkstückdichte pro Aufspannung ermöglichen.

Beim herkömmlichen Drahterodieren wird während des Betriebs kontinuierlich Messing- oder verzinkter Draht verbraucht. Die Drahtkosten machen bei hochpräzisen Bearbeitungen 15 bis 201.000 Tonnen der gesamten Betriebskosten aus. Der Draht muss für die Bearbeitung von Innenstrukturen durch Startlöcher geführt werden, was die Rüstzeiten erhöht und sich bei größeren Produktionsmengen summiert. Die Laserbearbeitung eliminiert diese Verbrauchskosten vollständig und ermöglicht die Bearbeitung von Innenstrukturen ohne vorgebohrte Zugangslöcher, da der Laser die Eintrittspunkte bei Bedarf direkt abtragen kann.

Die um 2001T³T höhere Durchsatzleistung, die mit laserbasiertem Diamantdrehen erzielt wird, wirkt sich direkt auf die Anlagenauslastung und die Rentabilität aus. Ein einzelnes Laserbearbeitungszentrum kann die Leistung von drei Drahterodieranlagen erreichen und reduziert so den Platzbedarf um 661T³T bei gleichzeitig sinkendem Energieverbrauch. Für Hersteller, die täglich Hunderte von Schneidwerkzeugeinsätzen verarbeiten, ermöglicht diese Produktivitätssteigerung die Deckung des Bedarfs mit weniger Maschinen und geringeren Investitionen in die Infrastruktur.

Der Geschwindigkeitsvorteil wird bei komplexen Geometrien, die mehrere Aufspannungen beim EDM-Verfahren erfordern, besonders deutlich. Ein typischer PKD-Fräseinsatz benötigt beispielsweise drei separate EDM-Aufspannungen für die Bearbeitung der Oberseite, der Umfangsgeometrie und der Fasen an der Unterseite. Mit RTCP-fähigem 5-Achs-Laserdrehen wird die gesamte Geometrie in einer einzigen Aufspannung bearbeitet. Dadurch entfallen die Werkstückhandhabungszeiten und die Positionierungsfehler, die sich bei mehreren Aufspannungen summieren.

Kantenausbrüche stellen eine anhaltende Herausforderung für die Qualitätskontrolle bei der Funkenerosion von polykristallinem Diamant dar. Der Funkenentladungsprozess erzeugt lokale thermische Spannungen, die zur Ausbreitung von Mikrorissen entlang der Korngrenzen führen können. Die Spanabmessungen variieren je nach Entladungsenergie zwischen 5 und 20 µm. Diese Kantenfehler reduzieren die Standzeit des Schneidwerkzeugs und können bei Hochgeschwindigkeitsbearbeitungen zu einem Totalausfall führen. Die Laserbearbeitung mit optimierten Pulsparametern erzeugt perfekte Schneidkanten ohne Beeinträchtigung der strukturellen Integrität. Dies wurde durch Rasterelektronenmikroskopie bestätigt, die bei 5000-facher Vergrößerung keine Mikrorisse zeigte.

Bei der Bearbeitung von PKD-Diamanten mit großen Partikeln, deren einzelne Kristallite einen Durchmesser von über 10 µm aufweisen, kommt es häufiger zu Materialrissen während der Funkenerosion. Die bei der Funkenentladung entstehenden thermischen Spannungen konzentrieren sich an den Partikelgrenzen und initiieren Risse, die sich über die gesamte Schneidkante ausbreiten können. Durch die Femtosekundenlaserablation wird dieser Fehlermechanismus vollständig vermieden, da Material abgetragen wird, bevor sich thermische Spannungen aufbauen.

Der Verzicht auf Kühlschmierstoffe stellt einen bedeutenden ökologischen und betrieblichen Vorteil des laserbasierten Diamantdrehens dar. Beim Drahterodieren werden 40–80 Liter deionisiertes Wasser pro Stunde verbraucht, das durch Elektrodenabriebpartikel und abgetragenes Werkstückmaterial verunreinigt wird und daher gefiltert und regelmäßig ausgetauscht werden muss. Die Entsorgungskosten und die Anforderungen an die Einhaltung von Umweltauflagen für die dielektrischen Flüssigkeiten beim Drahterodieren erhöhen die Betriebskosten pro Maschine um 2.000–5.000 € jährlich.

Die Reduzierung der Stellfläche um 40% beim Austausch von EDM-Systemen durch Laserbearbeitungszentren bietet zusätzliche Vorteile in Fertigungsbetrieben, in denen die Kosten pro Quadratmeter jährlich $50–150 betragen. Ein Lasersystem mit einer Stellfläche von 6 m² erzielt den gleichen Durchsatz wie EDM-Anlagen mit einem Platzbedarf von 10 m², wodurch die Betriebskosten um $2.000–6.000 pro Jahr gesenkt und gleichzeitig die Materialflusseffizienz verbessert wird.

5-Achs-CNC-Bearbeitungszentren für die Diamantbearbeitung integrieren hochentwickelte Steuerungssysteme, die mehrere Achsen mit submikron-Präzision koordinieren können. Die in führenden Systemen eingesetzte NUM-CNC-Steuerungsarchitektur zeichnet sich durch ein modulares NCK-Design (Numerischer Steuerungskern) aus, wobei jedes NUM-System aus bis zu 8 NCKs besteht. Diese skalierbare Architektur unterstützt 32 Achsen bzw. Spindeln pro NCK und ermöglicht so Systemkonfigurationen mit über 200 gesteuerten Achsen, wenn dies für komplexe Fertigungszellen oder die Koordination mehrerer Maschinen erforderlich ist.

Die offene Architektur gewährleistet Kompatibilität mit verschiedenen Werkzeugmaschinenanwendungen, darunter Drehen, Fräsen, Hobeln, Schleifen, Laserbearbeitung und Wasserstrahlschneiden. Diese Flexibilität ermöglicht es Herstellern, eine einheitliche Steuerungsplattform für ihre gesamte Fertigung zu etablieren, wodurch der Schulungsaufwand reduziert und die Wartung vereinfacht wird. Die Echtzeit-Bahninterpolation des Steuerungssystems hält die Bahngenauigkeit bei komplexen Fünf-Achs-Bewegungen innerhalb von 0,5 µm – unerlässlich für die Herstellung der geometrischen Komplexität, die in modernen Schneidwerkzeugkonstruktionen gefordert ist.

Linearmotorantriebe in Kombination mit Rollenführungssystemen bieten die für das hochpräzise Diamantdrehen erforderlichen dynamischen Ansprecheigenschaften. Im Gegensatz zu Drehservomotoren mit Kugelgewindetrieben erzeugen Linearmotoren den Schub direkt und ohne mechanische Übertragungskomponenten. Dadurch werden Spiel vermieden und die bewegte Masse reduziert. Diese Konfiguration erreicht Beschleunigungen von über 2,5 g (25 m/s²) bei gleichzeitiger Aufrechterhaltung von Steifigkeitswerten des Positionierregelkreises von 100–150 N/µm.

Die durch Linearmotorsysteme ermöglichte schnelle Reaktionszeit erweist sich insbesondere bei abrupten Richtungsänderungen während der Werkzeugwegausführung als äußerst wertvoll. Bei der Bearbeitung komplexer Spanbrecherstrukturen mit Radiusübergängen unter 0,1 mm haben mechanische Antriebssysteme aufgrund von Servoverzögerungen und mechanischer Nachgiebigkeit Schwierigkeiten, die Bahngenauigkeit zu gewährleisten. Linearmotorsysteme hingegen folgen den vorgegebenen Bahnen selbst bei starken Beschleunigungsprofilen mit einer Genauigkeit von 2 µm und sichern so die geometrische Präzision über den gesamten Bereich der Schneidwerkzeugmerkmale.

Moderne Steuerungssysteme ermöglichen die Echtzeit-Trajektorienberechnung mit einer Aktualisierungsrate von 50 kHz und damit die reibungslose Ausführung komplexer Freiformflächen ohne Geschwindigkeitsschwankungen, die Oberflächenartefakte verursachen. Die hohe Trajektorienpunktdichte – 50.000 Positionssollwerte pro Sekunde – gewährleistet eine adäquate Abtastung gekrümmter Werkzeugwege und verhindert den Facetteneffekt, der bei der linearen Interpolation von Kurven mit unzureichender Punktdichte auftritt.

Vorkalkulierte Stromprofile optimieren die Motorstromzufuhr bei komplexen Bewegungen und reduzieren so Folgefehler, die sich als Oberflächenwelligkeit äußern. Durch die Vorhersage des Drehmomentbedarfs für kommende Bahnsegmente kann das Regelsystem die Motorströme vorausschauend anpassen und so eine präzisere Bahnverfolgung gewährleisten, als dies allein durch Rückkopplungskorrektur möglich wäre. Diese Vorsteuerungsfunktion reduziert Folgefehler um 60–801 TP3T im Vergleich zu reinen Rückkopplungsregelungsstrategien.

Spezielle CAM-Software (Computer-Aided Manufacturing) für Diamantdrehanwendungen vereinfacht die Programmierung für Hersteller, die von der Funkenerosion auf die Laserbearbeitung umsteigen. Diese Systeme importieren Werkzeuggeometrien als DXF-Dateien, generieren automatisch 3D-Werkzeugwege unter Berücksichtigung der RTCP-Kinematik und ermöglichen realistische Simulationen direkt an der Maschinensteuerung. Über die parametrisierte Softwareoberfläche können Bediener Standardwerkzeuggeometrien – Schaftfräser, Planfräser, Formwerkzeuge – definieren und die Bearbeitungsparameter automatisch an Materialvariationen und Qualitätsanforderungen anpassen.

Die automatische 3D-Vermessung der PKD-Oberflächenstruktur mittels integrierter Messsysteme liefert entscheidende Daten für die Werkzeugwegoptimierung. Durch die Messung der Geometrie des gesinterten PKD-Rohlings vor der Bearbeitung kompensiert das CAM-System Materialdickenschwankungen und Oberflächenunebenheiten und gewährleistet so eine gleichmäßige Abtragstiefe an der Schneidkante. Dieser geschlossene Regelkreis reduziert die Ausschussrate von 8–121 TP3T, wie sie bei manuellen Programmierverfahren üblich ist, auf unter 11 TP3T.

Online-Messsysteme mit integrierten KI-gestützten Fehlerkorrekturalgorithmen stellen den neuesten Stand der Qualitätssicherung beim Diamantdrehen dar. Diese Systeme nutzen hochauflösende Bildverarbeitung und Laserprofilometrie, um kritische Abmessungen während der Bearbeitung zu messen und die Ergebnisse in Echtzeit mit den CAD-Vorgaben zu vergleichen. Wird eine Maßabweichung festgestellt, passt das KI-System automatisch die Bearbeitungsparameter – Laserleistung, Vorschubgeschwindigkeit, Fokusposition – an, um die nachfolgenden Bearbeitungsschritte wieder innerhalb der Toleranzgrenzen durchzuführen.

Diese adaptive Regelungsfunktion erweist sich insbesondere bei langen Produktionsläufen als wertvoll, da thermische Drift, Laserleistungsabfall oder Materialeigenschaftenänderungen andernfalls zu Qualitätseinbußen führen könnten. Das KI-System lernt den Zusammenhang zwischen Prozessparametern und Maßergebnissen und erstellt Vorhersagemodelle, die notwendige Anpassungen antizipieren, bevor Toleranzgrenzen überschritten werden. Hersteller, die diese Systeme einsetzen, berichten von einer Erfolgsquote von 951 TP3T im ersten Durchgang und einer Reduzierung des Ausschusses von 3,51 TP3T auf unter 0,51 TP3T.

Die Femtosekundenlasertechnologie stellt den Gipfel der Präzision in der Diamantmikrobearbeitung dar und arbeitet mit Pulsdauern von ≤ 400 Femtosekunden (400 × 10⁻¹⁵ Sekunden). In diesem extrem kurzen Zeitraum legt das Licht lediglich 120 Nanometer zurück – eine Strecke, die kleiner ist als die Wellenlänge des sichtbaren Lichts. Diese zeitliche Präzision ermöglicht eine extrem präzise räumliche Energiezufuhr, minimiert die Wärmediffusion in das umgebende Material und eliminiert die für Lasersysteme mit längeren Pulsdauern typischen Wärmeeinflusszonen.

Die Materialwechselwirkungsphysik bei der Femtosekunden-Laserablation unterscheidet sich grundlegend von der Nanosekunden- oder Dauerstrichlaserbearbeitung. Wenn die Laserpulsdauer sich der Elektron-Phonon-Kopplungszeit (typischerweise 1–10 Pikosekunden für Diamant) annähert oder diese unterschreitet, erfolgt die Energiedeposition schneller als der thermische Ausgleich. Die absorbierte Energie erzeugt ein überhitztes Plasma, das explosionsartig expandiert und Material mechanisch abträgt, bevor eine signifikante Wärmeleitung stattfindet – ein Prozess, der trotz der extremen momentanen Temperaturen als „kalte Ablation“ bezeichnet wird.

Die mit 0,08 μm Ra erzielte Oberflächenrauheit stellt eine zehnfache Verbesserung gegenüber herkömmlichen Schleifverfahren für Präzisionsdiamantbauteile dar. Diese Oberflächenqualität macht die meisten Nachbearbeitungsschritte überflüssig, da die bearbeitete Oberfläche die Spezifikationen für die direkte Montage in Präzisionsmechanismen erfüllt. Für optische Anwendungen, bei denen Streulicht minimiert werden muss, erzeugt die Femtosekundenlaserbearbeitung Oberflächen mit einer RMS-Rauheit im Subnanometerbereich über für die optische Streuung relevanten Ortsfrequenzen (0,1–1 mm⁻¹).

Die deterministische Natur der Femtosekundenlaserbearbeitung – bei der jeder Puls ein vorhersagbares Materialvolumen abträgt – ermöglicht ausgefeilte Oberflächenbearbeitungsstrategien. Durch die Variation von Pulsüberlappungsmustern und Energiedichten können Hersteller kontrollierte Oberflächenstrukturen erzeugen, die tribologische Eigenschaften optimieren, die Haftung für nachfolgende Beschichtungsprozesse verbessern oder optische Mikrostrukturen für Anwendungen im Lichtmanagement herstellen.

Die durch kontrollierte Femtosekundenlaserbearbeitung erreichte Kantenpassivierungsgenauigkeit von 5 µm verlängert die Standzeit des Schneidwerkzeugs im Vergleich zu Werkzeugen, die mit Nanosekundenlasersystemen hergestellt werden, um das Dreifache. Die Spezifikation des Schneidkantenradius beeinflusst die Schneidleistung direkt: Zu scharfe Kanten (Radius < 3 µm) führen unter Stoßbelastung zu vorzeitigem Ausbrechen, während zu große Radien (> 8 µm) die Schnittkräfte und die Oberflächenrauheit des Werkstücks erhöhen.

Für eine gleichmäßige Kantenbearbeitung ist eine präzise Steuerung der Laserfokusposition relativ zur Schneide erforderlich – durch aktive Fokusnachführungssysteme wird diese auf ±2 μm genau eingehalten. Der Laserstrahl durchläuft den Kantenbereich in mehreren Durchgängen, wobei jeweils 1–2 μm Material abgetragen werden. So wird die gewünschte Radiusgeometrie aufgebaut, ohne die Spannungsspitzen zu erzeugen, die bei einem starken Abtrag in einem einzigen Durchgang auftreten würden.

Spanbrechernuten und spiralförmige Schlitze stellen Geometrien dar, deren Herstellung bei ultraharten Werkstoffen mit konventionellen Verfahren besonders schwierig ist. Spanbrecherstrukturen mit einer Teilung von 0,1 mm und einer Tiefe von 0,05 mm kontrollieren die Spanbildung beim Zerspanen und verhindern so lange, fadenförmige Späne, die Werkstückoberflächen beschädigen und Sicherheitsrisiken bergen. Die Femtosekundenlaserbearbeitung ermöglicht die Herstellung dieser dreidimensionalen Strukturen mit einer Positionsgenauigkeit von ±3 μm und gewährleistet die Einhaltung der geometrischen Spezifikationen über die gesamte Produktionsmenge hinweg.

Spiralnuten in PKD- und CBN-Schneidwerkzeugen ermöglichen eine effiziente Spanabfuhr beim Bohren und Stirnfräsen. Die Spiralgeometrie – typischerweise ein Spiralwinkel von 30–45° – erfordert die koordinierte Bewegung aller fünf Achsen, während der Fokus des Lasers auf der gekrümmten Oberfläche beibehalten wird. Die RTCP-Funktionalität gewährleistet, dass der Laserpunkt während des gesamten Spiralwegs senkrecht zur momentanen Oberflächennormalen bleibt, wodurch ein gleichmäßiger Materialabtrag und eine konsistente Oberflächengüte erzielt werden.

Die Erhaltung der kristallinen Materialstruktur ohne Phasenübergänge ist ein entscheidender Vorteil der Femtosekundenlaserbearbeitung gegenüber thermischen Bearbeitungsverfahren. Vergleichende Analysen mittels Raman-Spektroskopie zeigen, dass Werkzeuge, die mit Femtosekundentechnologie bearbeitet wurden, ihre ursprüngliche sp³-gebundene Diamantstruktur über die gesamte bearbeitete Fläche beibehalten, während die Nanosekundenlaserbearbeitung nachweisbaren graphitischen Kohlenstoff (sp²-Bindung) erzeugt, der sich 5–10 µm von den Schnittflächen erstreckt.

Das Ausbleiben einer Phasenumwandlung gewährleistet, dass Härte, Verschleißfestigkeit und Wärmeleitfähigkeit bis zur Schneidkante den vorgegebenen Werten entsprechen. Diese Materialintegrität ist besonders wichtig für Schneidwerkzeuganwendungen, bei denen die Schneidentemperaturen während Hochgeschwindigkeitsbearbeitungen 800 °C übersteigen – Bedingungen, unter denen sich jede bereits vorhandene Graphitumwandlung rasch ausbreiten und zu einem katastrophalen Werkzeugversagen führen würde.

Die Luft- und Raumfahrtindustrie ist auf 5-Achs-Bearbeitung angewiesen, um asphärische Linsen und Freiformspiegel für Satellitenbildsysteme, Head-up-Displays in Flugzeugen und Infrarot-Zielsensoren herzustellen. Diese optischen Komponenten erfordern eine Oberflächengenauigkeit von besser als λ/10 Spitze-Tal (ca. 60 nm) in Kombination mit einer Oberflächenrauheit von unter 2 nm RMS. Das Diamantdrehen von Aluminium- oder Kupfersubstraten – gefolgt von einer stromlosen Vernickelung für bestimmte Anwendungen – ist das einzig wirtschaftlich sinnvolle Fertigungsverfahren für Prototypen oder mittlere Serien, bei denen die Kosten für Spritzgusswerkzeuge nicht gerechtfertigt sind.

Die Fertigung von Freiformoptiken nutzt die Fünf-Achsen-Fähigkeit, um nicht-rotationssymmetrische optische Oberflächen zu erzeugen, die Aberrationen effizienter korrigieren als herkömmliche sphärische oder asphärische Designs. Diese fortschrittlichen optischen Designs ermöglichen leichtere und kompaktere Systeme – entscheidende Vorteile für Anwendungen in der Luft- und Raumfahrt, wo jedes Gramm Gewichtsersparnis zu Treibstoffeinsparungen oder einer höheren Nutzlastkapazität führt. Industrielasermaschinen hergestellt Für diese Anwendungen müssen Formgenauigkeitsvorgaben von 100 nm PV über 100 mm Durchmesser Optiken erreicht werden.

Präzisionschirurgische Schneidinstrumente aus PCD weisen im Vergleich zu Edelstahlalternativen eine deutlich höhere Schnitthaltigkeit auf und können daher über mehrere Sterilisationszyklen hinweg wiederverwendet werden, bevor ein Nachschärfen erforderlich ist. Ophthalmologische Skalpellklingen, Arthroskopie-Shaver und orthopädische Schneidinstrumente profitieren von der durch Femtosekundenlaser-Diamantdrehen erzielbaren Schneidschärfe von 0,001 mm. Die biokompatiblen Oberflächen – frei von Mikrorissen und Eigenspannungen – verhindern die Anhaftung von Bakterien und erleichtern die für wiederverwendbare Medizinprodukte erforderlichen Reinigungsprotokolle.

Mikrofluidische Gerätekomponenten für die patientennahe Diagnostik erfordern komplexe dreidimensionale Kanalgeometrien mit Positionstoleranzen von ±5 µm, um eine zuverlässige Flüssigkeitsführung zu gewährleisten. Das Diamantdrehen von Spritzgusswerkzeugeinsätzen ermöglicht die wirtschaftliche Fertigung dieser Geräte, sobald die Designs stabilisiert sind. Die optisch hochwertige Oberflächengüte diamantgedrehter Formen macht die üblicherweise erforderlichen Polierarbeiten überflüssig. Die Oberflächenrauheit der Form überträgt sich direkt auf das Formteil und ermöglicht so mikrofluidische Kanäle mit einer Oberflächenrauheit von unter 100 nm. Dies minimiert den Strömungswiderstand und verhindert die Anhaftung von Partikeln.

PKD-Schneidwerkzeuge für die Bearbeitung von Automobilmotoren erzielen eine 5- bis 10-fach höhere Produktivität als Hartmetallwerkzeuge bei der Bearbeitung von Aluminium-Zylinderköpfen, Motorblöcken und Getriebegehäusen. Die extreme Härte und der niedrige Reibungskoeffizient von PKD ermöglichen Schnittgeschwindigkeiten von über 2000 m/min – weit jenseits der thermischen Grenzen von beschichtetem Hartmetall – und gewährleisten gleichzeitig die Maßgenauigkeit über lange Produktionsläufe hinweg. Ein typischer PKD-Planfräseinsatz bearbeitet 50.000 Aluminium-Zylinderköpfe, bevor er ausgetauscht werden muss, im Vergleich zu 5.000 Teilen bei hochwertigen Hartmetalleinsätzen.

Die Oberflächenbearbeitung von Getriebekomponenten profitiert besonders von CBN-Werkzeugen, die mittels 5-Achs-Laser-Diamantdrehen hergestellt werden. Gehärtete Stahlzahnräder (58–62 HRC) und Lagerringe erfordern Schneidwerkzeugmaterialien, die ihre Härte bei hohen Temperaturen beibehalten und gleichzeitig abrasivem Verschleiß widerstehen. CBN-Werkzeuge mit präzise kontrollierter Schneidkantenpräparation – mit einem Radius von 8–12 µm für ein optimales Verhältnis zwischen Schneidkantenfestigkeit und Schnittkraft – ermöglichen Oberflächenbearbeitungen, die eine Oberflächenrauheit von 0,4 µm Ra direkt im Schneidprozess erreichen und somit nachfolgende Schleifvorgänge überflüssig machen.

Die 3C-Elektronikindustrie (Computer, Kommunikationstechnik, Unterhaltungselektronik) treibt die Nachfrage nach Mikroschneidwerkzeugen an, die Aluminium, Magnesium und Verbundwerkstoffe bearbeiten können, welche in Smartphone-Gehäusen, Tablet-Computer-Gehäusen und Gehäusen für tragbare Geräte verwendet werden. Diese Werkzeuge weisen typischerweise Schneidkantenabmessungen unter 0,1 mm und eine Schneidkantenradius von 2–3 µm auf, um die Gratbildung bei der Bearbeitung dünnwandiger Strukturen zu minimieren.

Die Bearbeitung dieser Mikrostrukturen in PCD-Material erweitert die Grenzen der Präzisionsfertigung. Die Werkstückabmessungen nähern sich der Korngröße des polykristallinen Diamantmaterials an, wodurch eine Femtosekundenlaserbearbeitung erforderlich ist, um saubere Kanten ohne Partikelausriss zu erzielen. Die Produktionserfahrung zeigt, dass Werkzeuge, die mit diesen fortschrittlichen Verfahren hergestellt werden, die Maßvorgaben innerhalb von ±2 µm über Produktionsläufe von mehr als 10.000 Einheiten einhalten – eine Wiederholgenauigkeit, die für die automatisierte Montage von Unterhaltungselektronik unerlässlich ist, da die Maßgenauigkeit die Qualität der Endmontage bestimmt.

Verarbeitung von im Labor gezüchteten Diamanten Anlagenbetreiber berichten von einer Reduzierung der Bearbeitungszeit um 661 TP3T durch den Einsatz des 5-Achs-Laser-Diamantdrehens für die Bearbeitung von Edelsteinen in Edelsteinqualität. Traditionelle Facettierverfahren basieren auf dem mechanischen Polieren mit diamantbesetzten Schleifscheiben – ein arbeitsintensiver Prozess, der Fachkräfte erfordert und bei komplexen Brillantschliffen 8–12 Stunden pro Karat in Anspruch nimmt. Das laserbasierte Diamantdrehen automatisiert den Facettierprozess und erzielt eine Erfolgsquote von 951 TP3T beim ersten Durchgang bei gleichzeitiger Reduzierung der Bearbeitungszeit auf 3–4 Stunden pro Karat.

Die wirtschaftliche Transformation erweist sich insbesondere für Diamanten mit komplexen Schliffen, die aufgrund ihrer anspruchsvollen Geometrie hohe Preise erzielen, als äußerst bedeutsam. Lasersysteme ermöglichen die präzise Ausführung firmeneigener Schliffmuster – geschützt durch Geschäftsgeheimnisse oder Designpatente – und gewährleisten so, dass jeder Stein die photometrischen Spezifikationen für Brillanz und Feuer erfüllt. Dank dieser Technologie können Hersteller von im Labor gezüchteten Diamanten ihre Produkte durch einzigartige Schliffmuster differenzieren, die mit manuellen Poliermethoden wirtschaftlich nicht reproduzierbar sind.

Vertikale 5-Achs-Bearbeitungszentren sind die gängigste Konfiguration für Diamantdrehanwendungen und bieten im Vergleich zu horizontalen Anordnungen eine überlegene Späneabfuhr und bessere Bedienbarkeit. Bei dieser vertikalen Konfiguration ist die B-Achse (typischerweise ein Schwenk-Rundtisch) horizontal und die C-Achsen-Spindel vertikal ausgerichtet. Durch diese Anordnung unterstützt die Schwerkraft die Späneabfuhr aus der Bearbeitungszone, wodurch das Risiko von Spänen, die sich wieder ablagern und die Oberflächenqualität beeinträchtigen könnten, reduziert wird.

Vertikale Konfigurationen bieten ergonomische Vorteile beim Einrichten von Werkzeugen und beim Beladen von Werkstücken. Die Bediener erreichen die Werkbank in einer komfortablen Arbeitshöhe (800–1000 mm über dem Boden), was die Ermüdung bei längeren Produktionsschichten reduziert. Der offene Maschinenraum ermöglicht das Beladen mit größeren Werkstücken im Vergleich zu horizontalen Konfigurationen, bei denen die maximale Werkstückgröße durch die Raumhöhe begrenzt ist.

Die Tragfähigkeit von Werkbänken, die von 100 kg für Kompaktsysteme bis zu 300 kg für produktionsorientierte Maschinen reicht, bestimmt die maximale Werkstückgröße und die Komplexität der Spannvorrichtung, die bei Einhaltung der geforderten Genauigkeit möglich sind. Der C-Achsen-Drehtisch muss neben der Werkstückmasse auch die Spannvorrichtung sowie die dynamischen Belastungen durch die Beschleunigungen während der Drehbewegung tragen. Systeme für schwere Werkstücke verfügen über Lager mit größerem Durchmesser und leistungsstärkere Antriebsmotoren, allerdings auf Kosten einer reduzierten maximalen Drehzahl.

Die Lastverteilung auf der Werkbank hat einen erheblichen Einfluss auf die Positioniergenauigkeit, da Momentenbelastungen durch außermittige Werkstücke Lagerverformungen verursachen, die sich als Positionierfehler bemerkbar machen. Moderne Systeme kompensieren die positionsabhängige Lagersteifigkeit in Echtzeit, indem sie mathematische Modelle der Lagerverformung verwenden, um die Sollpositionen anhand der tatsächlichen Werkstückposition und Massenverteilung anzupassen.

Die Werkzeughalterschnittstellen HSK-A63 und BT50 sind Industriestandards für die Präzisionsbearbeitung. Die HSK-Bauweise (Hohlschaft-Kegel) bietet Vorteile bei der Hochgeschwindigkeitsbearbeitung durch die Kontaktfläche und den Kegel, die die Haltekraft auch bei hohen Drehzahlen durch Zentrifugalkräfte aufrechterhält. Der Hohlschaft reduziert das Gewicht im Vergleich zu Vollschaftalternativen, ermöglicht höhere Beschleunigungswerte und verringert Vibrationen bei schnellen Werkzeugwechseln.

BT50 (in Nordamerika auch als CAT50 bekannt) bietet eine bewährte Alternative mit breiter Werkzeugverfügbarkeit und geringeren Halterkosten. Die 7/24-Kegelgeometrie gewährleistet zuverlässige Zentrierung und Wiederholgenauigkeit, wobei die Zugbolzen-Halterung Haltekräfte von über 15 kN erzeugt. Für Diamantdrehanwendungen, bei denen die Spindeldrehzahlen selten 5000 U/min überschreiten, bietet das BT50-System eine ausreichende Leistung zu geringeren Implementierungskosten als HSK-Alternativen.

Das Lasersystem nutzt ein modulares Strahlführungssystem, das schnelle Konfigurationsänderungen für unterschiedliche Wellenlängen oder Leistungsstufen ermöglicht. Das Strahlführungssystem beinhaltet hochpräzise Galvanometerscanner mit einer Positioniergenauigkeit von 2 Mikroradian, was eine Punktpositioniergenauigkeit von ±5 μm über ein Sichtfeld von 100 mm ermöglicht. Das Galvanometersystem arbeitet mit Scanfrequenzen von über 1 kHz und ermöglicht so eine schnelle Flächenstrukturierung für Oberflächentexturierungsanwendungen.

Integrierte CCD-Kameras unterstützen die Werkstückpositionierung und ermöglichen die Prozessüberwachung. Die koaxiale Anordnung – bei der die Kamera durch denselben optischen Pfad wie der Bearbeitungslaser arbeitet – erlaubt die Echtzeitüberwachung der Laser-Interaktionszone. Fortschrittliche Bildverarbeitungsalgorithmen erkennen Kantenpositionen für die automatische Werkstückausrichtung und reduzieren die Rüstzeit von 15–20 Minuten bei manueller Messung auf 2–3 Minuten mit Bildverarbeitungsunterstützung.

Maschinenbetten aus Naturmarmor bieten außergewöhnliche thermische Stabilität und Schwingungsdämpfungseigenschaften, die für eine Positioniergenauigkeit im Sub-5-Mikrometer-Bereich unerlässlich sind. Der niedrige Wärmeausdehnungskoeffizient von Granit (5–8 × 10⁻⁶ pro °C) in Kombination mit seiner hohen spezifischen Wärmekapazität (750 J/kg·K) minimiert Dimensionsänderungen durch Umgebungstemperaturschwankungen. Die Dämpfungskapazität des Materials – etwa 10-mal höher als die von Gusseisen – leitet Schwingungsenergie von externen Quellen schnell ab und gewährleistet so die Positioniergenauigkeit selbst in Anlagen mit in der Nähe befindlichen schweren Förderanlagen.

Die Maschinenbasis ist mit pneumatischen Schwingungsisolationssystemen ausgestattet, die die Präzisionsmaschinenstruktur von den vom Boden übertragenen Schwingungen entkoppeln. Diese Systeme gewährleisten eine konstante Maschinenhöhe und Resonanzfrequenzen unter 2 Hz – deutlich unterhalb der Eigenfrequenzen der Maschinenstruktur (typischerweise 60–150 Hz). Das Isolationssystem reduziert die Übertragung von Bodenschwingungen um 90–951 µT, was insbesondere für Anlagen in der Nähe von Straßen oder Bahnstrecken, wo Fahrzeugverkehr periodische Störungen verursacht, von entscheidender Bedeutung ist.

Die Entwicklung der 5-Achs-Diamantdrehtechnologie in Kombination mit Femtosekundenlaserbearbeitung stellt einen bahnbrechenden Fortschritt in der Ultrapräzisionsfertigung von superharten Werkstoffen dar. Die Möglichkeit, bei der Bearbeitung von PCD-, CBN- und CVD-Diamantwerkstoffen eine Maßgenauigkeit von 0,003 mm mit 2001T3T-fach höheren Geschwindigkeiten als bei herkömmlichen EDM-Verfahren zu erreichen, verändert die Wirtschaftlichkeit der Präzisionswerkzeugproduktion grundlegend. Hersteller, die diese Systeme einsetzen, berichten von einer Reduzierung der Stückkosten um 501T3T bei gleichzeitiger Beseitigung der Qualitätsprobleme – wie Ausbrüche an der Schneidkante, Materialrisse und thermische Schäden –, die herkömmliche Bearbeitungsverfahren beeinträchtigen.

Die Kombination aus fortschrittlicher Bewegungssteuerung, RTCP-Kinematik und ultraschneller Laserphysik ermöglicht geometrische Komplexität, die bei superharten Materialien bisher unmöglich war. Von der Luft- und Raumfahrtoptik mit Oberflächengenauigkeit im Nanometerbereich bis hin zu Medizinkomponenten mit biokompatiblen Oberflächen – das 5-Achs-Laser-Diamantdrehen liefert Spezifikationen, die mit mechanischen Bearbeitungsverfahren nicht erreichbar sind. Die ökologischen Vorteile der Technologie – kein Kühlschmierstoffverbrauch, 40% weniger Platzbedarf – unterstützen die Nachhaltigkeitsinitiativen der Fertigungsindustrie und verbessern gleichzeitig die Wirtschaftlichkeit.

Für Hersteller, die sich durch präzise Fertigungsmöglichkeiten Wettbewerbsvorteile sichern wollen, bietet die Investition in moderne 5-Achs-Laser-Diamantdrehmaschinen messbare Vorteile durch kürzere Zykluszeiten, höhere Qualität und erweiterte Anwendungsmöglichkeiten. Die Technologie beseitigt herkömmliche Hürden bei der Bearbeitung nichtleitender, superharter Werkstoffe und eröffnet gleichzeitig neue Gestaltungsmöglichkeiten für komplexe dreidimensionale Geometrien, die die Leistung der Schneidwerkzeuge optimieren.

Sind Sie bereit, Ihre Präzisionsfertigungskapazitäten zu transformieren? Erfahren Sie, wie. Die fortschrittlichen 5-Achs-Laserbearbeitungszentren von OPMT Wir liefern die für die moderne Bearbeitung von superharten Materialien erforderliche Genauigkeit, Geschwindigkeit und Zuverlässigkeit. Kontaktieren Sie unser technisches Team, um anwendungsspezifische Lösungen für Ihre Anforderungen in der Luft- und Raumfahrt, Medizintechnik, Automobilindustrie oder im Präzisionswerkzeugbau zu besprechen.

Das traditionelle Diamantdrehen nutzt zwei bis drei lineare Achsen (X, Z und gegebenenfalls Y) mit einer rotierenden Spindel zur Herstellung rotationssymmetrischer Teile wie sphärischer oder asphärischer Linsen. Diese Konfiguration beschränkt die Fertigung auf Rotationsflächen, bei denen jeder Querschnitt senkrecht zur Rotationsachse die gleiche Geometrie aufweist. Das 5-Achs-Diamantdrehen ergänzt die Bearbeitung um zwei Rotationsachsen (typischerweise die B-Achse für die Neigung und die C-Achse für die Rotation), die die gleichzeitige Positionierung des Werkzeugs relativ zum Werkstück in beliebiger Ausrichtung ermöglichen.

Diese erweiterte kinematische Fähigkeit ermöglicht die Fertigung von nicht rotationssymmetrischen Freiformflächen, die für moderne optische Konstruktionen unerlässlich sind, sowie von Schneidwerkzeugen mit komplexen Spanbrechergeometrien und Bauteilen mit Hinterschnitten oder negativen Entformungsschrägen, die mit herkömmlichen Methoden nicht realisierbar sind. Die RTCP-Funktion (Rotation Tool Center Point) hält die Laserfokusposition während komplexer Mehrachsenbewegungen konstant und gewährleistet so eine gleichmäßige Bearbeitung der gesamten Werkstückgeometrie unabhängig von der Achsenorientierung.

Moderne 5-Achs-CNC-Bearbeitungszentren für die Diamantbearbeitung erreichen eine Positioniergenauigkeit von 0,005 mm (5 Mikrometer) mit einer Wiederholgenauigkeit von 0,003 mm über den gesamten Arbeitsbereich. Diese durch Laserinterferometrie verifizierten Spezifikationen belegen die Fähigkeit der Maschine, den Laserfokuspunkt auch bei längeren Produktionsläufen zuverlässig an den vorgegebenen Koordinaten zu positionieren.

Die erzielbare Oberflächenrauheit hängt von den Materialeigenschaften und Prozessparametern ab. Femtosekundenlasersysteme liefern konstant Ra-Werte unter 0,1 µm auf polykristallinen Diamantmaterialien – führende Systeme erreichen sogar 0,08 µm Ra auf Präzisionsbauteilen. Die Formgenauigkeit für optische Anwendungen liegt typischerweise unter λ/10 (ca. 60 nm im sichtbaren Wellenlängenbereich), wodurch die direkte Herstellung optisch hochwertiger Oberflächen ohne nachfolgende Polierprozesse möglich ist.

Die Rotationsachsen B und C gewährleisten eine Positioniergenauigkeit von 10 Bogensekunden bei einer Wiederholgenauigkeit von 5 Bogensekunden, was einer Positionsunsicherheit von unter 5 µm bei typischen Arbeitsradien entspricht. Diese Rotationsgenauigkeit ist für Anwendungen mit Schneidwerkzeugen unerlässlich, da bereits Abweichungen des Freiwinkels von 0,1° die Werkzeugleistung und -standzeit erheblich beeinträchtigen.

Ja – dies ist einer der größten Vorteile des laserbasierten Diamantdrehens gegenüber der Funkenerosion (EDM). EDM erfordert die elektrische Leitfähigkeit des Werkstücks, um die für den Materialabtrag notwendige Funkenentladung zu erzeugen. Großkörniger polykristalliner Diamant, bestimmte CVD-Diamantsorten und Verbundwerkstoffe mit Diamant in nichtleitenden Matrixen weisen eine unzureichende Leitfähigkeit für eine zuverlässige EDM-Bearbeitung auf.

Bei der Bearbeitung dieser Werkstoffe mittels Drahterodieren führt die geringe Leitfähigkeit zu unregelmäßiger Funkenbildung – einem Phänomen, das als „Drahtüberspringen“ bezeichnet wird. Dies verursacht eine unregelmäßige Schnittgeometrie, Maßungenauigkeiten und häufigen Drahtbruch, was eine Unterbrechung des Bearbeitungsprozesses erforderlich macht. Die Laserbearbeitung beseitigt diese grundlegende Einschränkung vollständig, da die photonenbasierte Energieübertragung unabhängig von den elektrischen Eigenschaften des Werkstücks funktioniert.

Diese Fähigkeit erweist sich als besonders wertvoll für Hersteller, die im Labor gezüchtete Diamantmaterialien verarbeiten, bei denen Spezifikationen für Kristallreinheit und Wärmeleitfähigkeit CVD-Wachstumsprozesse erfordern, die elektrisch isolierendes Material erzeugen. Femtosekundenlaser-Diamantbearbeitung Die Systeme verarbeiten diese Materialien mit der gleichen Zuverlässigkeit und Präzision wie elektrisch leitfähige Alternativen und erweitern so die Anwendungsmöglichkeiten für fortschrittliche Materialqualitäten.

Die Wirtschaftlichkeitsanalyse zeigt, dass die laserbasierte Diamantbearbeitung mit 50% im Vergleich zu konventionellen EDM-Verfahren bei der Bearbeitung superharter Werkstoffe geringere Bearbeitungskosten pro Einheit aufweist. Dieser Kostenvorteil beruht auf mehreren Faktoren: dem Wegfall der Kosten für Drahtverbrauchsmaterialien (typischerweise $ 0,10–0,25 pro Meter bei einem Verbrauch von 2–5 Metern/Minute), kürzeren Zykluszeiten, die 200% einen höheren Durchsatz bei gleicher Investition in die Anlagen ermöglichen, und dem Wegfall des Elektrodenverschleißes, der einen regelmäßigen Austausch erforderlich machen würde.

Der Geschwindigkeitsvorteil – 3,0 mm/min Materialabtrag beim Laser gegenüber 1,5 mm/min beim EDM – führt direkt zu geringeren Lohnkosten pro Teil und einer verbesserten Anlagenauslastung. Ein einzelnes Laserbearbeitungszentrum erreicht die Produktionskapazität von 2–3 EDM-Anlagen und reduziert den Kapitalbedarf an Anlagen bei gleichem Produktionsvolumen um 661 TP³T. Die damit verbundenen Einsparungen bei Stellfläche (401 TP³T weniger benötigte Fläche), Energieverbrauch (kein System zur Erzeugung von deionisiertem Wasser erforderlich) und Wartungsaufwand tragen zusätzlich zu den Gesamtbetriebskostenvorteilen bei.

Die Reduzierung der Ausschussrate ist ein weiterer wichtiger wirtschaftlicher Faktor. Bei der herkömmlichen EDM-Bearbeitung von PKD-Schneidwerkzeugen treten Ausschussraten von 8–121 TP3T aufgrund von Kantenausbrüchen, Materialrissen und Maßtoleranzüberschreitungen auf. Moderne Lasersysteme mit KI-gestützter Fehlerkorrektur senken die Ausschussraten auf unter 11 TP3T, verbessern die Materialausnutzung und eliminieren Nachbearbeitungskosten. Für Hersteller, die teure PKD-Rohlinge verarbeiten (1 TP4T50–200 pro Rohling, abhängig von Größe und Güte), führt diese Qualitätsverbesserung zu erheblichen Materialkosteneinsparungen.

Die Luft- und Raumfahrtindustrie** stellt das größte Anwendungssegment dar und nutzt das Diamantdrehen für die Fertigung von Präzisionsoptiken, darunter asphärische Linsen, Freiformspiegel, Infrarotfenster und Komponenten zur Laserstrahlformung. Die Technologie ermöglicht Oberflächengüten in optischer Qualität (Ra < 10 nm) bei gleichzeitiger Einhaltung von Formgenauigkeitsvorgaben besser als λ/10 (Spitze-Tal). Dadurch lassen sich komplexe optische Geometrien wirtschaftlich und ohne aufwendige Polierprozesse fertigen.

Medizintechnikunternehmen setzen auf das 5-Achs-Laser-Diamantdrehen zur Herstellung chirurgischer Schneidinstrumente aus PKD-Material. Die damit erzielbaren Kantenschärfen unter 3 µm Radius sind essenziell für die Minimierung von Gewebetrauma. Die biokompatiblen Oberflächen – frei von Mikrorissen und Eigenspannungen – erfüllen die strengen regulatorischen Anforderungen für wiederverwendbare chirurgische Instrumente. Auch die Herstellung mikrofluidischer Geräte für diagnostische Anwendungen profitiert von der Möglichkeit, komplexe dreidimensionale Kanalgeometrien mit einer Positioniergenauigkeit von unter 5 µm in Formwerkzeugen zu realisieren.

Hersteller von Schneidwerkzeugen für die Automobilindustrie nutzen die Technologie zur Produktion von PCD- und CBN-Wendeschneidplatten, die bei der Serienbearbeitung von Aluminium-Motorkomponenten, Getriebegehäusen und Bremsanlagenteilen eingesetzt werden. Herstellung von Präzisionsschneidwerkzeugen Durch den Einsatz von 5-Achs-Lasersystemen wird eine 5- bis 10-fach höhere Werkzeugstandzeit im Vergleich zu Hartmetallalternativen erreicht, wodurch die Werkzeugkosten pro gefertigtem Fahrzeugbauteil sinken. Hersteller von im Labor gezüchteten Diamanten nutzen diese Technologie, um die Bearbeitungszeit für Edelsteine um 661 TP3T zu reduzieren und gleichzeitig eine Erfolgsquote von 951 TP3T beim ersten Schliff zu erzielen. Dies revolutioniert die Wirtschaftlichkeit der Produktion von Diamanten mit besonderen Schliffen.

Haftungsausschluss

Dieser Inhalt wurde von OPMT Laser auf Grundlage öffentlich verfügbarer Informationen zusammengestellt und dient ausschließlich zu Referenzzwecken. Die Erwähnung von Marken und Produkten Dritter dient dem objektiven Vergleich und stellt keine kommerzielle Verbindung oder Billigung dar.

Entdecken Sie die Welt der CNC-Bearbeitung, indem wir 3-Achsen- und 5-Achsen-Technologien vergleichen. Von einfachen Vorgängen bis hin zu komplexen Geometrien – finden Sie heraus, welche Maschine Ihren Fertigungsanforderungen im Jahr 2025 entspricht.

Entdecken Sie OPMTs bewährten 5-Phasen-ODM-Prozess für kundenspezifische Lasersysteme. ISO-zertifizierte Fertigung, Präzision ±0,003 mm, IP-Schutz. Senden Sie uns noch heute Ihre Projektanforderungen.

Suchen Sie nach den besten Anbietern für 5-Achsen-CNC-Bearbeitungszentren? In unserer Top-10-Liste finden Sie Expertenwissen und die perfekte Lösung für Ihre Anforderungen!

Entdecken Sie die 10 besten Laser-Metallschneidmaschinen des Jahres 2025, darunter Branchenführer wie Trumpf, Bystronic und OPMT Laser. Vergleichen Sie Spitzentechnologie, Präzision und Effizienz, um die perfekte Lösung für Ihre Fertigungsanforderungen zu finden.

Bitte geben Sie Ihre Kontaktinformationen ein, um das PDF herunterzuladen.