Vereinbaren Sie einen Besuch

Egal ob Sie eine allgemeine Beratung oder spezifische Unterstützung benötigen, wir helfen Ihnen gerne weiter.

Egal ob Sie eine allgemeine Beratung oder spezifische Unterstützung benötigen, wir helfen Ihnen gerne weiter.

Alle News

Aktie

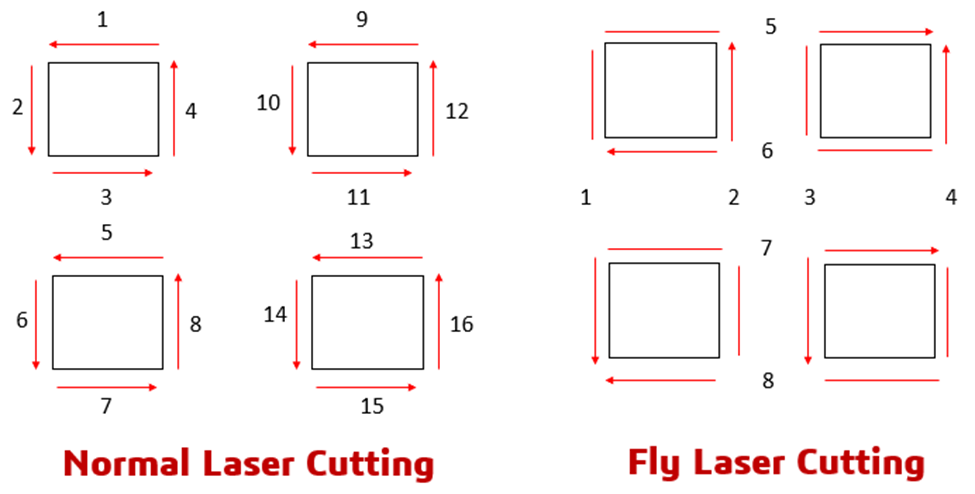

Traditional laser cutting systems waste up to 40% of cycle time repositioning between cuts. The laser head stops, moves to the next feature, stops again, and repeats this pattern hundreds or thousands of times per part. Fly cut laser technology eliminates this inefficiency through continuous motion path optimization.

The difference is straightforward: instead of the laser head stopping at each cut location, it moves continuously while the beam activates and deactivates in sync with the motion. For manufacturers processing sheet metal parts with multiple holes or features, this translates to 30-50% faster throughput and measurably lower operating costs.

OPMT develops 5-axis and multi-axis CNC systems integrated with ultrafast laser processing technology. Our LP550V and LightMut 750V systems apply fly cutting to superhard materials—PCD, CBN, hard alloys—where traditional methods struggle. This guide covers the technical mechanics, real-world limitations, software requirements, and implementation considerations for fly cut laser processing across aerospace, medical device, automotive, and precision tooling applications.

Fly cutting is an on-the-fly processing mode where the laser head moves continuously while the beam activates and deactivates based on the cutting path. Unlike traditional sequential cutting, where the machine stops at each feature, fly cutting treats the entire workpiece as a continuous path problem.

The system analyzes the part geometry and plans an optimized route—typically a grid pattern using horizontal and vertical cutting lines. When processing a sheet with 200 holes, the laser head follows this predetermined path without stopping between features. The beam switches on when the head crosses a feature location and switches off in the spaces between.

Path optimization replaces sharp angular changes with tangential radius transitions. Instead of the head jerking from one direction to another at 90-degree corners, it follows smooth curves that reduce mechanical stress on guide rails and bearings. On systems with linear motors, this extends component life by reducing peak acceleration loads.

The “fly” terminology comes from the continuous motion concept—the cutting head “flies” across the workpiece surface rather than making discrete stop-start movements. Some manufacturers call this grid cutting, continuous cutting, or on-the-fly processing. They mean the same thing: synchronized motion and beam control.

Traditional sequential cutting processes features one at a time: cut hole 1, move, cut hole 2, move, cut hole 3. Fly cutting processes features in bulk: follow optimized path, activate beam at hole locations 1, 2, 3, 4…200. The time saved accumulates rapidly on parts with dozens or hundreds of features.

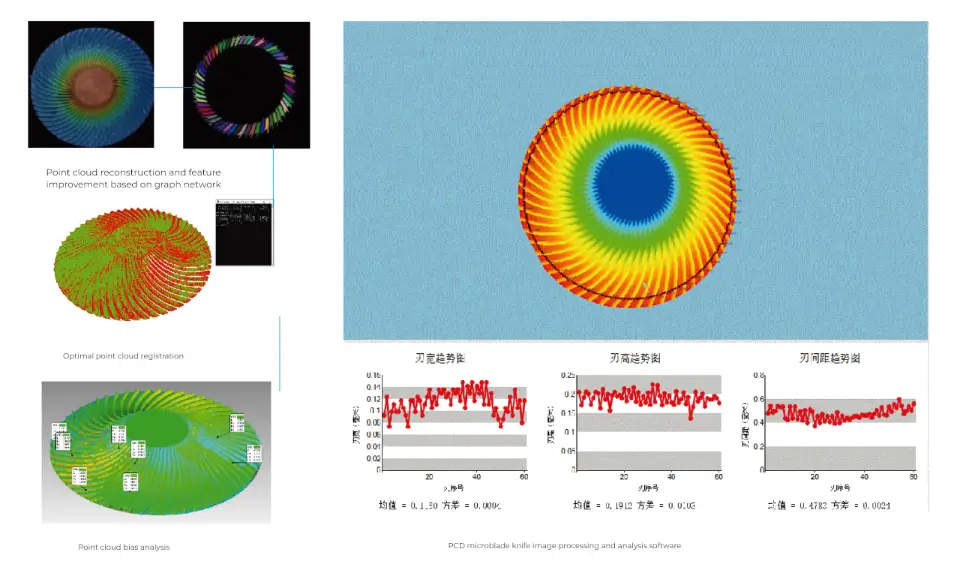

Real-world testing on OPMT systems shows measurable gains. Processing 10,000 0.5mm diameter holes in 1mm stainless steel takes approximately 2.8 hours with sequential cutting versus 1.4 hours with fly cutting—a 50% reduction in cycle time.

Path optimization starts with geometry analysis. The software examines the part file and identifies all cutting features, then determines an efficient sequence that minimizes total travel distance. For sheet metal with distributed holes, this typically produces a grid pattern with alternating horizontal and vertical passes.

The algorithm considers multiple factors: total path length, direction changes, beam activation frequency, and thermal management. Parts with features clustered in one area get different path strategies than parts with evenly distributed features.

Laser activation control requires precise timing. The CNC controller monitors the actual position of the cutting head through closed-loop feedback from grating scales. When the head reaches a feature location, the controller sends a signal to activate the laser. When the feature is complete, it deactivates the beam. This happens hundreds of times per minute during fly cutting operations.

Multi-axis coordination is where fly cutting gets complex. OPMT systems integrate linear motors for X/Y/Z axes with direct-drive rotation axes for A/B/C positioning. Linear motors provide faster acceleration than ball screws—our Light 5X 40V achieves 30 m/min rapid traverse speed with positioning accuracy of ±0.005mm.

The closed-loop system uses grating scales that provide 0.001mm resolution feedback. The controller compares commanded position to actual position thousands of times per second. Any deviation triggers corrective motion. This maintains accuracy even during continuous high-speed movement.

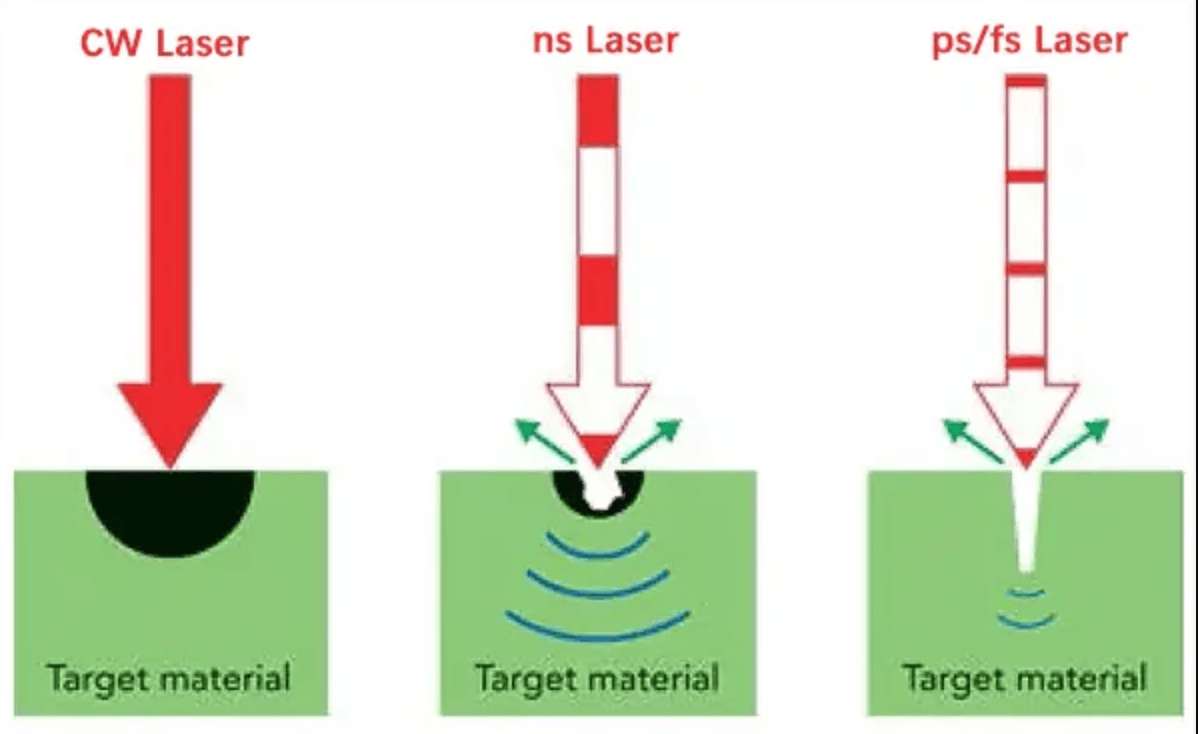

Beam path modularization means the laser delivery system is designed as a plug-and-play unit. OPMT systems use modular beam paths with integrated CCD positioning cameras and high-precision probes. The modular design simplifies maintenance and allows different laser sources (nanosecond, picosecond, femtosecond) to be swapped based on application requirements.

CCD positioning integration adds vision-based verification. Before starting a fly cutting operation, the system captures an image of the workpiece to verify alignment. Some operators use this for automatic offset correction when processing multiple parts with slight positioning variations.

The practical limit is synchronization accuracy. At 20 m/min cutting speed, the head travels 333mm per second. Activating the laser 0.001 seconds late results in a 0.33mm positional error. OPMT controllers achieve sub-millisecond response times, keeping activation errors below 0.05mm.

For complex geometries requiring rotation, the system coordinates up to 5 axes simultaneously. The LP550V processes polycrystalline diamond (PCD) cutting inserts with compound angles by rotating the A-axis while X/Y/Z axes follow the contour path. The controller calculates the inverse kinematics in real-time to maintain the correct beam-to-workpiece relationship.

Cycle time drops by 30-50% for parts with multiple features. The exact reduction depends on feature density and spacing. Parts with 100+ holes see the largest gains because repositioning time dominates traditional processing. Parts with 10-20 large features see smaller improvements because cutting time exceeds repositioning time.

Energy efficiency improves because the laser head isn’t constantly accelerating and decelerating. Acceleration requires peak power draw from the drive motors. Continuous motion at steady velocity consumes less power than repeated stop-start cycles. On a typical production day processing 50 sheets, this reduces electricity consumption by 12-18%.

Material utilization improves through kerf optimization. Fly cutting allows more flexible nesting strategies because the path planning algorithm can handle arbitrary feature sequences. Traditional nesting often leaves unusable remnants between parts. Fly cutting processes these remnants without time penalty, improving material utilization by 15-25% on complex nested layouts.

Slug generation decreases. In traditional cutting, each feature produces a slug that drops through the table or requires removal. With fly cutting, some features can be processed with micro-tabs (small connecting points) that hold slugs in place until the entire sheet is processed. This reduces the risk of slug interference with the laser head during cutting.

Machine lifespan extends through reduced wear on mechanical components. Linear guide rails and ball screws experience less cyclic stress when motion is continuous rather than repetitive start-stop. OPMT systems using fly cutting show approximately 30% longer bearing life based on accelerated wear testing.

Part quality improves in some applications through more consistent heat distribution. Sequential cutting allows each feature to cool completely before processing the next feature. Fly cutting processes features in quick succession, which can be good or bad depending on material and thickness. For thin stainless steel sheets, the continuous thermal input actually reduces warping by preventing localized stress concentrations.

ROI metrics are straightforward. A shop processing 1000 parts per month with 50 features each sees 700 hours saved annually through 30% cycle time reduction. At $75/hour shop rate, that’s $52,500 in recaptured capacity. The shop can either increase volume or reduce overtime costs.

Throughput increases enable same-day turnaround on orders that previously required next-day completion. For high-volume production environments processing automotive stamping dies or semiconductor component carriers, this matters. Parts that previously took 8 hours now finish in 4-5 hours, allowing two batches per shift instead of one.

Material thickness restrictions are real. Fly cutting works best on materials ≤1.5mm thick. Thicker materials require slower cutting speeds and higher laser power, which limits the speed advantage of continuous motion. On 3mm stainless steel, traditional cutting at 2.5 m/min often produces better results than fly cutting at 3.5 m/min because the beam activation timing becomes harder to control.

Reflective materials complicate fly cutting. Stainless steel and aluminum reflect 80-95% of incident laser energy at 1064nm wavelength. This low absorption rate requires careful control of beam focus and assist gas to initiate and maintain cutting. During fly cutting, the rapid on-off cycles make it harder to establish stable cutting conditions, particularly at thin sections where heat dissipates quickly.

Complex geometry requires decomposition. Fly cutting works best with features that can be described as horizontal and vertical lines—holes, slots, rectangles. Curved features like tight-radius arcs or complex splines don’t decompose cleanly into fly cutting paths. You end up with a hybrid approach: fly cut the simple features, then switch to traditional mode for complex contours.

Heat accumulation risks are specific to certain materials. Titanium alloys and high-nickel superalloys are sensitive to thermal gradients. Fly cutting processes features in rapid succession, which can cause heat buildup at certain locations. This compromises material integrity through phase changes or residual stress. For aerospace parts requiring full material traceability, this is a real concern that requires thermal modeling and validation.

Collision prevention matters more during fly cutting. At 20 m/min, the laser head moves fast enough that collision with a tilted slug can damage optics. Traditional cutting allows time to verify each slug dropped properly before moving to the next feature. Fly cutting assumes everything clears correctly. Most systems use high-pressure assist gas (15-20 bar) to force slugs through the table, but this doesn’t work reliably for all geometries.

Accuracy trade-offs exist. Traditional cutting achieves ±0.05mm positional accuracy because the head is stationary during beam activation. Fly cutting achieves ±0.1-0.15mm because the head is moving when the beam activates. For precision applications requiring tight tolerances, this matters. Medical implant components often can’t accept 0.1mm positional variation.

Edge quality varies by material and thickness. On thin materials (0.5-1mm), fly cutting often produces edges comparable to traditional cutting. On thicker materials (2-3mm), the edge perpendicularity and surface roughness may be inferior because the beam doesn’t dwell long enough to establish full-thickness penetration before moving on.

Software complexity increases. The CAM software must handle path planning, collision detection, thermal simulation, and real-time motion control. Not all laser cutting software supports fly cutting, and those that do require operator expertise to set parameters correctly. Poor parameter choices (too fast, wrong beam switching frequency) produce scrap parts.

CypCut provides comprehensive CAD/CAM functionality with dual-drive position error correction. The software analyzes part geometry and automatically generates fly cutting paths based on user-defined parameters: maximum jump distance, micro-tab size, grid line spacing. Dual-drive correction compensates for mechanical backlash in systems using ball screws rather than linear motors.

The interface allows operators to visualize the cutting path before processing. You can see exactly where the laser will activate and deactivate, and adjust parameters if the automatic path looks wrong. This saves material by catching errors in simulation rather than during production.

Cut Assist v2.0 by ANCA Motion takes a different approach with operator-friendly controls that don’t require CAM expertise. The software presents sliders for laser width (0.05-0.5mm), cutting speed (1-30 m/min), and beam switching frequency (1-10 kHz). Operators adjust these parameters based on material type and thickness without needing to understand the underlying path planning algorithms.

This makes sense for shops with multiple operators who have varying skill levels. The senior programmer sets up the baseline parameters, then operators make minor adjustments for specific materials or part geometries. The software includes a knowledge base of recommended settings for common material/thickness combinations.

HypCut optimizes high-power laser systems (6-15kW) for cutting strategy and material usage efficiency. The software includes a nesting engine that arranges parts on the sheet to minimize total cutting path length while maintaining proper lead-in/lead-out spacing. For fly cutting applications, this is critical because inefficient nesting eliminates the time savings from continuous motion.

HypCut also manages assist gas usage, which matters for high-volume production. Nitrogen assist gas costs $0.50-1.50 per sheet depending on local prices. Optimized cutting paths reduce gas consumption by 10-15% through shorter cutting times and better flow management.

Path planning algorithms use several techniques for fly cutting optimization. Intelligent micro-tab settings create 0.1-0.3mm connection points that hold parts in place during cutting, then the operator removes finished parts by snapping the tabs. This eliminates the need for part-holding fixtures on nested layouts.

Maximum jump distance configuration (1-5mm) tells the software how far the head can travel without cutting before it should re-evaluate the path. Short jump distances produce more efficient paths for closely-spaced features. Long jump distances work better for widely-spaced features where backtracking saves more time than additional path complexity.

Precision control parameters achieve 0.01mm recognition deviation accuracy in determining when features overlap or connect. This matters for parts with tangent features or shared edges. The software must correctly identify these relationships to avoid double-cutting or missing edges.

OPMT systems use the NEWCON IM 8 CNC controller, which interfaces with CypCut, Cut Assist, and HypCut through standard G-code and proprietary extensions. The controller handles real-time motion interpolation—calculating X/Y/Z/A/B positions 1000 times per second to maintain smooth continuous motion while activating/deactivating the laser at precise positions.

Some shops develop custom post-processors to optimize the CAM output for their specific machines. This requires programming expertise but allows fine-tuning of acceleration profiles, corner rounding, and beam switching timing based on actual machine capabilities rather than generic software defaults.

Aerospace manufacturers use fly cut laser processing for PCD cutting tool production. Polycrystalline diamond inserts for aluminum alloy machining require precise edge geometry with 0.02mm tolerances. Traditional EDM takes 45-60 minutes per insert. OPMT’s LP550V processes these parts in 15-20 minutes using femtosecond laser fly cutting with simultaneous 5-axis positioning.

Turbine blade processing benefits from fly cutting’s ability to handle complex curved surfaces. The blade cooling holes (0.3-0.8mm diameter) are positioned at compound angles through the blade thickness. The LP550V rotates the part on A/B axes while the laser head follows the optimized path, processing 40-60 holes per blade in a single setup.

Lightweight alloy component fabrication for aircraft structures requires minimal heat-affected zones. Femtosecond lasers produce nearly zero thermal damage because pulse duration is too short for heat diffusion. Combined with fly cutting’s rapid processing, this allows drilling hundreds of precision holes in aluminum-lithium alloy panels without warping or metallurgical changes.

Medical device manufacturers process surgical instrument blanks from 440C stainless steel and titanium alloys. The parts have multiple features—holes for screws, slots for blade attachment, profiled edges for ergonomics. Fly cutting reduces processing time from 25 minutes to 12 minutes per part, which matters when producing batches of 500-1000 instruments.

Implantable component machining uses biocompatible materials like Ti-6Al-4V and cobalt-chrome alloys. These materials are difficult to machine conventionally due to work hardening. Laser processing avoids mechanical contact, but traditional sequential cutting creates thermal gradients that alter material properties. Fly cutting with optimized beam parameters maintains consistent thermal input across the entire part.

Automotive manufacturers process battery tray components for electric vehicles. Each tray has 200-400 ventilation holes and cable routing slots. Processing time directly impacts production capacity. OPMT’s LightMut 750V processes complete battery trays in 8-10 minutes compared to 18-22 minutes with traditional methods.

Drivetrain component manufacturing includes gears, shafts, and mounting brackets with precision hole patterns for assembly. Parts made from hardened steel require laser processing because conventional drilling damages tooling. Fly cutting handles the batch processing requirements—dozens of parts per shift—without operator intervention.

Mold texturing for automotive trim parts uses laser ablation to create specific surface patterns. The texture might be a leather grain pattern or brushed metal effect. The pattern consists of thousands of small ablated features. Fly cutting processes these patterns 40-50% faster than sequential ablation.

Cutting tool manufacturers produce carbide inserts with complex geometries. An indexable milling insert has multiple cutting edges with precise chip breaker geometries. Processing a batch of 100 inserts takes 6-7 hours with sequential cutting versus 3.5-4 hours with fly cutting on OPMT’s Light 5X 60V system.

Complex geometry end mills with irregular flute spacing and variable helix angles require 5-axis positioning. The LightMut 750V coordinates laser cutting with rotary axis positioning to produce these features in a single operation.

Electronics manufacturers process precision housings for smartphones and tablets. The aluminum housings have holes for buttons, cameras, speakers, and ports. Each housing might have 20-30 features requiring tight positional tolerances (±0.08mm). Fly cutting maintains these tolerances while meeting production volume requirements of 10,000+ units per day.

Connector component processing includes small stampings with multiple holes and slots. Parts are 5-15mm in size with features as small as 0.2mm. Traditional methods struggle with these dimensions. Laser fly cutting handles the small scale and produces edge quality suitable for electrical contact surfaces.

Heat sink fabrication uses copper or aluminum with fin patterns for thermal management. Each heat sink has 30-80 fins with precise spacing and height. Laser cutting produces the fin pattern faster than stamping for low-to-medium volumes (1000-10,000 units), and fly cutting makes the economics work by cutting processing time in half.

The LP550V Five-Axis Ultrafast Laser Rotary Cutting Machine handles femtosecond and picosecond pulses with 520×640×480mm travel on X/Y/Z axes. Positioning accuracy is ±0.005mm with repeat positioning accuracy of ±0.003mm. The A-axis provides 360-degree rotation at 100-200 rpm, while the C-axis rotates at 3500-6000 rpm for high-speed indexing.

The system uses a direct-drive rotary stage with 125mm diameter capacity, suitable for cutting tool inserts, medical implants, and small aerospace components. Maximum load capacity is 10kg including fixturing. The laser source options include femtosecond (pulse duration <500fs) for zero thermal damage applications and picosecond (pulse duration 10-30ps) for higher throughput on less heat-sensitive materials.

The LP550V includes a rotary cutting optical module with entrance pupil diameter of 4.5mm and selectable focal lengths of 50mm or 60mm. This produces drilling diameters from 0.1-1mm with taper angles up to 6 degrees. The system achieves pit-depth to pit-diameter ratios of 15:1, useful for aerospace cooling holes and medical device fluid channels.

LightMut 750V Laser Grinding and Milling Compound Machining Center combines three laser sources in one machine: nanosecond for general cutting, picosecond for precision work, and femtosecond for minimal thermal impact. The system switches between laser sources automatically based on the programmed operation.

Travel is 600×600mm on X1/X2 axes (dual gantries) and 600mm on Y-axis, with 400mm Z-axis travel. The workbench measures 500×500mm with M10 threaded holes on 100mm spacing for flexible fixturing. Load capacity is 200kg for batch processing multiple parts simultaneously.

The LightMut 750V runs at 20-40 m/min feed rates with positioning accuracy of ±0.005mm. The dual-gantry design allows independent processing of two areas simultaneously, effectively doubling throughput for certain part geometries. Each gantry has its own Z-axis and beam delivery system.

Light 5X 40V is a vertical 5-axis laser machining center with 400mm X-axis travel, 250mm Y-axis, and 300mm Z-axis. The system uses linear motors on all three linear axes for fast response and high positioning accuracy. Linear rolling guide rails have low friction and fast acceleration—the machine achieves 30 m/min rapid traverse speed.

The bed is natural marble for thermal stability and vibration damping. Marble has thermal expansion coefficient of 8×10⁻⁶ per °C compared to 12×10⁻⁶ for cast iron, which means better dimensional stability during long production runs.

The machine integrates a 100W fiber laser with HSK-E40 or HSKA63 spindle interface. The B-axis provides 120-degree swing angle at 100-150 rpm rated speed. The C-axis rotates at 200-300 rpm rated speed with maximum load capacity of 10kg. This configuration handles PCD tool blanks, carbide inserts, and ceramic cutting tools.

Light 5X 60V extends the X-axis to 600mm while maintaining the same Y and Z travel. The larger work envelope accommodates automotive tooling and larger aerospace components. The system accepts a BT50 or HSKA63 tool holder interface with 40kg maximum C-axis load capacity including fixturing.

All OPMT systems use closed-loop grating scale feedback with 0.001mm resolution. The NEWCON IM 8 CNC controller processes this feedback data at 1kHz update rate, allowing real-time position correction during fly cutting operations.

Technical specifications include:

Modular design allows scaling for different production requirements. The beam path module, CCD positioning camera, and probe measurement system are separate assemblies that mount to the Z-axis. Operators can swap different laser sources or add specialized optical configurations without modifying the mechanical structure.

Cutting parameter optimization starts with material testing. Don’t trust generic parameter databases—verify settings on your actual material batches. Stainless steel from different suppliers can have significantly different carbon content, which affects laser absorption and cutting behavior.

Speed adjustments for material thickness follow a general rule: cutting speed decreases roughly proportionally to thickness squared. If you cut 1mm material at 20 m/min, expect to cut 2mm material at 5 m/min, not 10 m/min. The laser must penetrate deeper and remove more material volume, which requires exponentially more energy per unit length.

For fly cutting specifically, test the beam switching frequency. Faster switching (5-10 kHz) works well for small features and thin materials. Slower switching (1-3 kHz) is better for larger features and thicker materials because it allows the beam to stabilize between activations.

Fixture design for batch processing requires careful planning. The fixture must hold parts securely without interfering with the laser beam path. For fly cutting, you can’t use tall clamps or fixtures that extend above the workpiece surface because the continuously moving head will collide with them.

Vacuum fixtures work well for flat sheets. The workpiece sits on a perforated table with vacuum zones that hold it flat during processing. This allows fly cutting with minimal setup time between parts.

Customized work holding for 3D parts requires coordination with the part geometry. The LP550V processes PCD inserts using a multi-part fixture that holds up to 22 pieces simultaneously. Each piece is positioned and oriented so the beam can access all required features during the fly cutting sequence.

Assist gas pressure configuration prevents slug collision and ensures clean cuts. For fly cutting on thin materials (<1.5mm), use 15-20 bar nitrogen pressure. This is higher than the 10-12 bar typically used for sequential cutting because the slugs need to clear faster.

The gas nozzle position matters. Set the nozzle height to 0.5-1mm above the workpiece surface. Too close and the nozzle hits slugs. Too far and the gas pressure dissipates before reaching the cut zone, reducing cutting quality.

Cutting sequence definition typically uses left-to-right, top-to-bottom patterns for optimal thermal management. Processing all features on the left side before moving to the right side creates better heat dissipation than zig-zagging across the part.

Some materials benefit from different sequence strategies. When processing titanium alloys, a spiral pattern from outside to center often produces better results than a grid pattern because it avoids creating isolated hot zones.

Maintenance protocols extend machine life and maintain accuracy. Linear guide rails need lubrication every 500 operating hours using ISO VG 68 oil. Apply 2-3 drops per rail and cycle the axes through full travel to distribute the lubricant.

Optical component cleaning is critical for laser systems. Inspect the focusing lens weekly and clean it if you see any contamination. Use lens cleaning solution and optical-grade tissue—never touch the lens surface with fingers or shop rags.

Calibration schedules depend on production volume. High-volume shops (16+ hours daily operation) should verify positioning accuracy monthly using a laser interferometer or ballbar system. Low-volume shops can extend this to quarterly verification.

Integration with existing production workflows requires attention to file formats and data transfer. Most CAD systems export DXF or STEP files. Your CAM software must import these correctly and preserve feature relationships. Test the entire workflow before committing to production.

Upstream CAD preparation includes verifying that all features are closed contours with no gaps or overlapping lines. The CAM software can’t generate correct fly cutting paths if the geometry is ambiguous or incorrectly defined.

Downstream quality inspection uses coordinate measuring machines (CMM) or optical comparators to verify feature positions. Document the results and feed them back to the CAM programmer to refine cutting parameters.

Operator training takes 40-80 hours for basic competency on fly cutting systems. Operators need to understand the relationship between path planning parameters and actual cutting results. OPMT provides one-week on-site training after installation, covering inspection, operation, programming, and troubleshooting.

Safety protocols for Class IV laser systems are non-negotiable. The processing area must be fully enclosed with interlocked doors that stop the laser when opened. All operators wear laser safety glasses rated for the specific wavelength (typically OD 7+ for 1064nm). Establish clear procedures for lockout/tagout during maintenance.

Fly cut laser technology delivers measurable improvements in cycle time, energy consumption, and material utilization for precision manufacturing applications. The 30-50% reduction in processing time is achievable on parts with multiple features when the system is properly configured and operators understand the parameter relationships.

The technology isn’t suitable for all applications. Thick materials, complex curved geometries, and parts requiring ±0.05mm accuracy are better processed with traditional sequential cutting. Reflective materials need careful parameter development to achieve reliable results.

OPMT’s LP550V, LightMut 750V, and Light 5X series machines integrate fly cutting capabilities with 5-axis positioning and ultrafast laser sources. These systems handle applications from aerospace PCD tooling to medical device implants to automotive battery components.

Implementation requires attention to software selection, fixture design, parameter optimization, and operator training. The upfront investment in proper setup pays back through increased throughput and reduced operating costs.

For manufacturers processing 1000+ parts monthly with 20+ features per part, fly cutting typically achieves ROI within 12-18 months through increased capacity and reduced labor costs. Contact OPMT’s technical team to discuss your specific application requirements and arrange material testing on our systems.

Haftungsausschluss

Dieser Inhalt wurde von OPMT Laser auf Grundlage öffentlich verfügbarer Informationen zusammengestellt und dient ausschließlich zu Referenzzwecken. Die Erwähnung von Marken und Produkten Dritter dient dem objektiven Vergleich und stellt keine kommerzielle Verbindung oder Billigung dar.

Vergleich von Pikosekunden- und Nanosekunden-Lasersystemen für die industrielle Fertigung. Daten zur Wärmeeinflusszone, Verarbeitungsgeschwindigkeiten, Kostenanalyse und Anwendungskriterien der von OPMT eingesetzten Systeme.

PCD-Laserschneidmaschinen bieten eine Genauigkeit von 0,003 mm und eine dreimal schnellere Bearbeitung als EDM. Umfassender technischer Leitfaden zur Herstellung von Werkzeugen aus polykristallinem Diamant für die Luft- und Raumfahrt- sowie die Automobilindustrie.

Bewertungsrahmen für Fabriken zur Beschaffung von Laserschneidanlagen. Infrastrukturbewertung, Qualitätsmanagementsystemanalyse und Berechnung der Gesamtbetriebskosten auf Basis von über 30 Anlagenprüfungen.

Compare top 5-axis CNC machine manufacturers including DMG MORI, Mazak, and OPMT Laser. Technical specs, pricing tiers, and application guide for aerospace, automotive, and medical device industries.

Bitte geben Sie Ihre Kontaktinformationen ein, um das PDF herunterzuladen.