Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

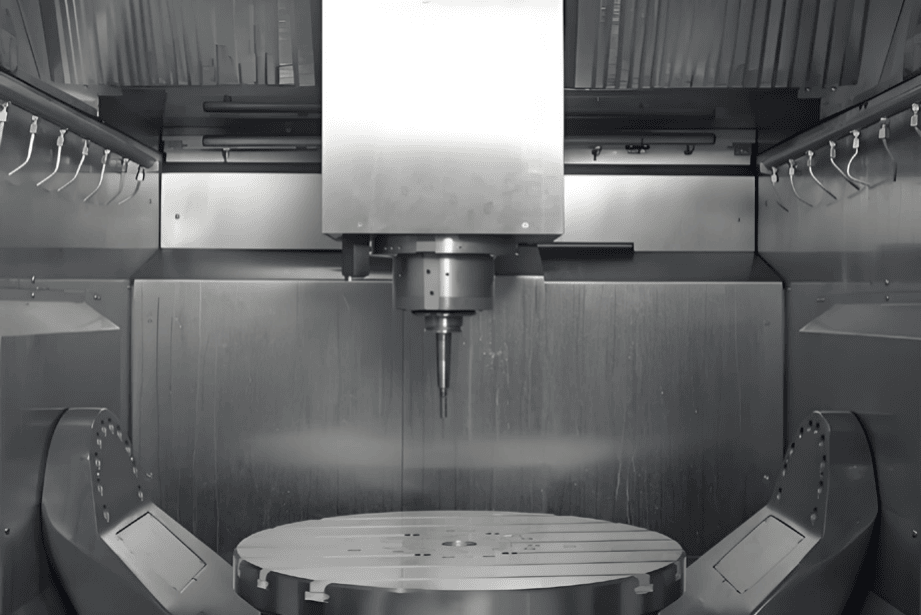

The dental manufacturing industry has undergone a revolutionary transformation through the integration of advanced CNC laser machining technologies. Modern dental CNC laser machining centers enable unprecedented precision in manufacturing titanium implants, ceramic crowns, and orthodontic devices while meeting stringent medical device standards. This comprehensive guide explores the cutting-edge technologies, applications, and operational considerations for dental manufacturers seeking to leverage OPMT Laser’s advanced machining solutions.

Dental CNC laser machining represents the convergence of multi-axis computer numerical control with ultrafast laser processing technologies. This sophisticated approach addresses the unique challenges of manufacturing biocompatible dental components that require sub-micron precision, exceptional surface quality, and strict adherence to medical device regulations.

Modern dental CNC systems utilize femtosecond and picosecond laser sources that operate with pulse durations ranging from 100 femtoseconds to several picoseconds. These ultrashort pulses enable precise material removal through photodisruption rather than thermal ablation, preserving the microstructural integrity of biomaterials.

The key advantages of ultrafast laser processing include:

OPMT Laser’s portfolio of dental CNC machining centers incorporates advanced multi-axis control systems, high-precision positioning mechanisms, and adaptive laser processing capabilities. The following table presents detailed specifications for OPMT’s leading dental machining platforms:

| Model Specification | Light 5X 40V | Light 5X 60V | MT30 Seven-Axis | Micro3D L570V |

|---|---|---|---|---|

| Axis Configuration | 5-axis | 5-axis | 7-axis | 5-axis |

| Maximum Workpiece Diameter | Ø100 mm | Ø200 mm | Ø320 mm | Ø125 mm |

| Maximum Workpiece Length | 200 mm | 350 mm | 250 mm | 200 mm |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.001 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.001 mm | ±0.0005 mm |

| Maximum Spindle Speed | 20,000 RPM | 25,000 RPM | 30,000 RPM | 40,000 RPM |

| Laser Power Output | 100W Fiber | 150W Fiber | 200W Fiber | Variable fs/ps |

| Pulse Duration Range | fs to ns | fs to ns | fs to ps | fs to ps |

| Control System | NUM Flexium+ | NUM Flexium+ 68 | NUM + AI Module | OPMT Intelligent |

| Workholding Capacity | 8 kg | 25 kg | 40 kg | 10 kg |

These systems incorporate linear motor drives for rapid acceleration and precise positioning, granite machine bases for thermal stability, and integrated metrology systems for real-time process control.

OPMT’s dental CNC laser machining centers address diverse manufacturing requirements across multiple dental device categories:

Titanium implant manufacturing demands exceptional precision in thread cutting, surface texturing, and dimensional control. OPMT’s systems achieve:

Ceramic materials including zirconia, alumina, and lithium disilicate require specialized processing parameters to prevent chipping and cracking. Key capabilities include:

Custom orthodontic brackets, wires, and attachments benefit from the flexibility of multi-axis laser machining:

Successful implementation of dental CNC laser machining requires systematic workflow optimization and adherence to established protocols. The following operational framework ensures consistent results and regulatory compliance:

The advantages of laser CNC machining over conventional manufacturing methods become evident through direct comparison:

| Performance Metric | Traditional CNC Milling | Conventional EDM | OPMT Laser Machining |

|---|---|---|---|

| Dimensional Accuracy | ±0.01-0.05 mm | ±0.005-0.02 mm | ±0.001-0.005 mm |

| Surface Finish (Ra) | 0.8-3.2 μm | 0.4-1.6 μm | 0.1-0.8 μm |

| Heat Affected Zone | Significant | Moderate | <10 μm |

| Tool Wear | High | Electrode wear | None |

| Setup Time | 2-4 hours | 1-3 hours | 15-30 minutes |

| Material Removal Rate | Limited by tool | 2-8 mm³/min | 5-15 mm³/min |

| Complex Geometry Capability | Limited | Good | Excellent |

| Thermal Damage Risk | High | Moderate | Negligible |

A leading dental implant manufacturer partnered with OPMT Laser to modernize their production capabilities, implementing the Light 5X 60V machining center for titanium implant processing. The comprehensive evaluation documented significant improvements across multiple performance metrics.

Production Efficiency Improvements:

Quality Enhancement Achievements:

Economic Impact Analysis:

The manufacturing engineer noted: “The transition to OPMT’s laser machining system fundamentally changed our production paradigm. We achieved precision levels previously impossible while dramatically reducing cycle times and eliminating quality variability.”

Learn more about similar implementations in our customer success stories.

Dental device manufacturing operates under stringent regulatory frameworks requiring comprehensive quality management systems and process validation. OPMT’s machining centers support compliance with key regulatory standards:

21 CFR Part 820 Quality System Regulation:

Device Classification and 510(k) Pathways:

OPMT’s integrated traceability solutions provide comprehensive device tracking capabilities:

Unique Device Identification (UDI) Compliance:

Process Documentation and Records:

Modern dental manufacturing environments increasingly leverage Industry 4.0 technologies for enhanced efficiency, quality, and flexibility. OPMT’s systems incorporate advanced digital manufacturing capabilities:

Explore OPMT’s intelligent manufacturing solutions for comprehensive Industry 4.0 integration.

Successful dental CNC laser machining requires detailed understanding of material properties and optimized processing parameters for each biomaterial category:

Ti-6Al-4V (Grade 5) Processing Parameters:

Surface Modification for Osseointegration:

Yttria-Stabilized Zirconia (3Y-TZP) Parameters:

Lithium Disilicate Glass-Ceramics:

316LVM Stainless Steel (Orthodontic Applications):

Learn more about material-specific applications in OPMT’s laser processing guide.

OPMT provides comprehensive training and support programs ensuring successful technology implementation and ongoing operational excellence:

Level 1: Operator Certification (80 hours)

Level 2: Process Engineer Certification (120 hours)

Level 3: Master Technician Certification (160 hours)

Technical Support Services:

Customer Success Metrics:

The dental manufacturing industry continues evolving toward increased personalization, sustainability, and digital integration. OPMT’s technology roadmap addresses these trends through continuous innovation:

Hybrid Manufacturing Systems:

Advanced Laser Technologies:

Personalized Medicine Integration:

Sustainability and Environmental Responsibility:

OPMT Laser’s dental CNC laser machining centers represent the pinnacle of precision manufacturing technology for dental device production. Through the integration of ultrafast laser processing, multi-axis CNC control, and intelligent manufacturing systems, these platforms enable dental manufacturers to achieve unprecedented levels of quality, efficiency, and regulatory compliance.

The comprehensive capabilities spanning titanium implant production, ceramic crown fabrication, and orthodontic appliance manufacturing position OPMT’s systems as essential tools for modern dental device manufacturers. With proven track records of successful implementations, robust technical support, and continuous innovation, OPMT Laser continues to advance the state-of-the-art in dental manufacturing technology.

For detailed technical specifications and application consultations, explore OPMT’s five-axis CNC laser machining centers or contact our applications engineering team for personalized solution development.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Discover laser galvanometer technology: operating principles, closed-loop vs open-loop systems, industrial applications, and integration with 5-axis CNC platforms for precision manufacturing.

Discover how advanced vertical 5-axis CNC systems achieve ±0.001-0.005mm micron-level precision for aerospace, medical, and automotive applications in 2026.

Comprehensive guide to 5-axis laser cutting machines: technology principles, advantages over 3-axis systems, industrial applications, and specifications for precision manufacturing.

Discover how 5-axis laser engraving machines deliver micron-level precision for complex surface marking, mold texturing, and industrial component identification across aerospace, automotive, and medical sectors.

Please fill in your contact information to download the PDF.