Programar una visita

Independientemente de si necesita asesoramiento general o apoyo específico, estaremos encantados de ayudarle.

Independientemente de si necesita asesoramiento general o apoyo específico, estaremos encantados de ayudarle.

Todas las noticias

Compartir

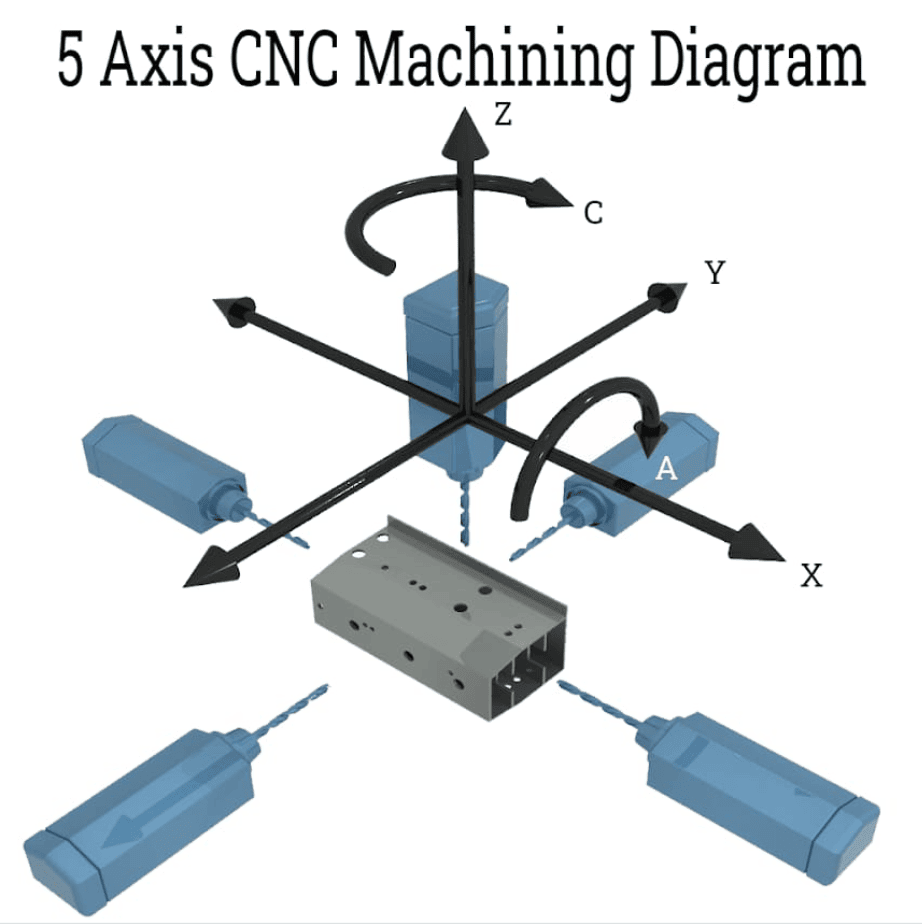

En resumen: Las operaciones de mecanizado de 5 ejes permiten el movimiento simultáneo en tres ejes lineales (X, Y, Z) y dos ejes de rotación (A/B o B/C), lo que proporciona capacidades de corte multidireccionales. Los dos modos de operación principales son el mecanizado simultáneo de 5 ejes, donde todos los ejes se mueven continuamente durante el corte, y el posicionamiento indexado (3+2), donde los ejes de rotación se bloquean en ángulos específicos para el mecanizado de 3 ejes. Estas operaciones reducen el tiempo de configuración en 65%, logran una precisión de posicionamiento de ±0,005 mm y permiten el procesamiento de geometrías complejas en componentes de turbinas aeroespaciales, implantes médicos y aplicaciones de herramientas automotrices.

El corte de 5 ejes representa un avance fundamental en la fabricación de precisión, permitiendo a los fabricantes procesar geometrías complejas imposibles con los sistemas convencionales de 3 ejes. Comprender las diferencias operativas entre el mecanizado simultáneo e indexado, junto con la selección adecuada de la configuración, influye directamente en la eficiencia de la producción, la precisión de las piezas y los costes de fabricación. Esta guía examina los principios técnicos de las operaciones de 5 ejes, las opciones de configuración y las aplicaciones específicas de la industria para ayudar a los ingenieros de fabricación a optimizar sus estrategias de procesamiento multieje.

La clasificación operativa de los sistemas de mecanizado de 5 ejes se divide en dos enfoques fundamentales, cada uno con ventajas diferenciadas para escenarios de fabricación específicos. El mecanizado simultáneo de 5 ejes, también conocido como contorneado continuo, ejecuta un movimiento coordinado en los cinco ejes durante las operaciones de corte activas. Este movimiento continuo permite que la herramienta de corte mantenga ángulos de contacto óptimos en superficies curvas complejas, eliminando así las limitaciones geométricas inherentes al procesamiento de 3 ejes.

El mecanizado indexado de 5 ejes, comúnmente conocido como posicionamiento 3+2, funciona mediante un enfoque secuencial. Los ejes de rotación (normalmente B y C) posicionan la pieza en ángulos predeterminados y la bloquean, mientras que los tres ejes lineales realizan operaciones estándar de mecanizado de 3 ejes. Este método ofrece las ventajas de acceso geométrico del posicionamiento multieje, a la vez que mantiene la simplicidad de programación y la estabilidad del corte con orientación fija.

La diferencia técnica entre estos enfoques se manifiesta en la calidad del acabado superficial y la capacidad geométrica. Las operaciones simultáneas logran acabados aproximadamente 40% más suaves que el posicionamiento indexado, especialmente en superficies de curvas compuestas, gracias al ajuste continuo de la trayectoria de la herramienta, que elimina las líneas de unión creadas por cambios de ángulo discretos. Sin embargo, el posicionamiento indexado ofrece una precisión superior para características planas, ya que los ejes de rotación bloqueados evitan los errores de posicionamiento dinámico que pueden ocurrir durante la interpolación simultánea multieje.

La selección del modo de operación depende de tres factores principales: la complejidad de la geometría de la pieza, los requisitos de acabado superficial y el volumen de producción. Los componentes que requieren acabados con un Ra de 0,4 μm en superficies esculpidas requieren operaciones simultáneas, mientras que las piezas prismáticas con múltiples caras planas que alcanzan un Ra de 0,8 μm suelen beneficiarse de los tiempos de programación más rápidos y la mayor estabilidad del 60% de posicionamiento indexado durante operaciones de desbaste con alta capacidad de arranque de material.

El mecanizado simultáneo de cinco ejes implementa el Control del Punto Central de la Herramienta en Tiempo Real (RTCP), un sistema computacional que ajusta continuamente la orientación de la herramienta para mantener ángulos de corte óptimos durante el procesamiento de contornos complejos. Los algoritmos RTCP calculan correcciones posicionales instantáneas en los cinco ejes, compensando las interacciones geométricas entre los movimientos lineales y rotacionales que, de otro modo, generarían errores dimensionales en las piezas terminadas.

La capacidad de interpolación continua en todos los ejes elimina las líneas de mezcla visibles que aparecen al cambiar entre orientaciones de corte. Esta transición fluida resulta crucial para aplicaciones aeroespaciales, donde los conductos de refrigeración de los álabes de turbina requieren una continuidad superficial ininterrumpida para evitar la concentración de tensiones. Avanzado. Centros de mecanizado CNC de 5 ejes para taladrado Aproveche las operaciones simultáneas para ejecutar secuencias de perforación de ángulo compuesto, logrando tolerancias angulares de ±0,5° en aleaciones de titanio sin reposicionamiento intermedio.

Las ventajas de aplicación del corte simultáneo se extienden a sectores de fabricación de alto valor:

La implementación del OPMT Light 5X 60V demuestra capacidades avanzadas de corte simultáneo mediante motores de par de accionamiento directo en ejes de CA que logran una precisión de posicionamiento de ±10 arcosegundos. Esta precisión, combinada con motores lineales en los ejes X, Y y Z que proporcionan velocidades de avance rápido de 30 m/min, permite reducciones del tiempo de ciclo superiores a 66% para fresadoras de conformado escalonado para automoción, en comparación con los métodos de procesamiento EDM convencionales. La integración del láser de femtosegundos del sistema amplía las operaciones simultáneas de 5 ejes a... femtosegundo Procesamiento de materiales superduros PCD y CBN, logrando una precisión dimensional de 0,003 mm y eliminando las zonas de daño térmico inherentes al mecanizado por descarga eléctrica.

El posicionamiento indexado de 5 ejes funciona mediante posicionamiento angular discreto con ejes rotatorios bloqueados durante las operaciones de corte, combinando el acceso geométrico multieje con la estabilidad del mecanizado en 3 ejes. El principio operativo divide las secuencias de mecanizado en fases de preparación y fases de corte, donde los ejes rotatorios se mueven entre operaciones, pero permanecen estacionarios durante la retirada de material.

El proceso de configuración sigue una secuencia sistemática:

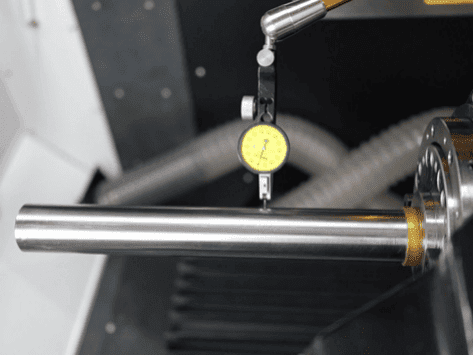

Las ventajas de precisión del posicionamiento indexado se deben a la estabilidad del eje bloqueado, que evita los errores de posicionamiento dinámico inherentes a la interpolación simultánea multieje. Cuando los ejes de rotación permanecen fijos, las fuerzas de corte no pueden inducir desplazamiento angular, lo que garantiza que las características planas mantengan tolerancias de planitud inferiores a 0,01 mm en superficies de hasta 500 mm de diámetro. Esta estabilidad resulta esencial para componentes estructurales aeroespaciales que requieren patrones precisos de orificios para pernos en superficies de ángulo compuesto.

La eficiencia de la programación representa una ventaja operativa significativa, ya que las operaciones indexadas reducen el tiempo de desarrollo del programa en aproximadamente 60% en comparación con las trayectorias de herramientas simultáneas. Las técnicas estándar de programación 2.5D se aplican a cada posición indexada, lo que permite a los fabricantes aprovechar sus conocimientos de CAM de 3 ejes sin invertir en una compleja formación en programación simultánea de 5 ejes. Esta accesibilidad hace que el posicionamiento indexado sea óptimo para la producción en lotes de gran volumen superior a 500 unidades, donde la inversión inicial en programación se amortiza en grandes series de producción.

Las aplicaciones ideales para el mecanizado 3+2 incluyen componentes prismáticos con múltiples caras planas que requieren relaciones de perpendicularidad precisas, como bloques de colectores hidráulicos con pasajes perforados transversalmente, carcasas de transmisión que requieren mecanizado de orificios en ángulos compuestos y bases de moldes con superficies de montaje en ángulo. Torneado de diamante de 5 ejes Las operaciones empleadas en la fabricación de óptica de precisión con frecuencia utilizan posicionamiento indexado para mantener la precisión geométrica en superficies planas torneadas con diamante.

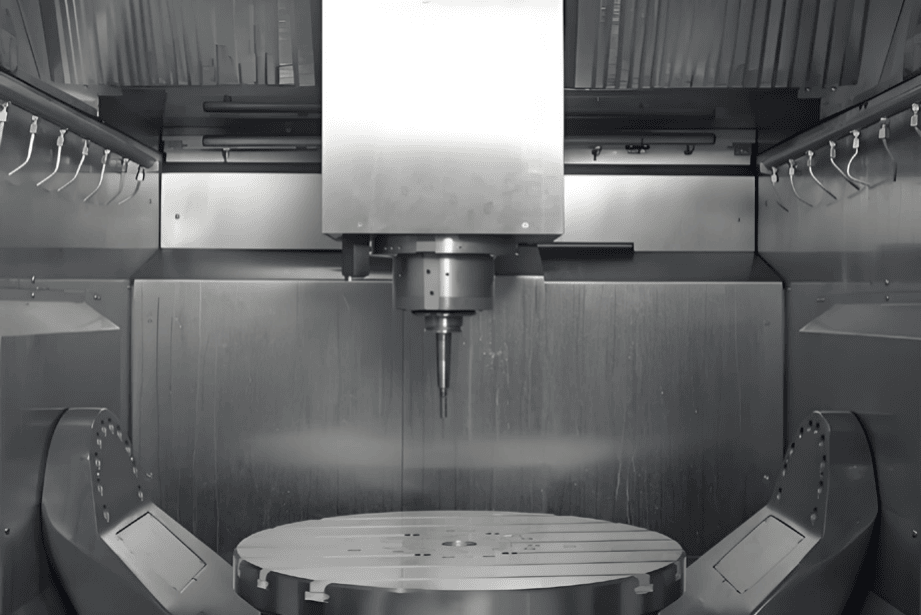

Las configuraciones físicas de la máquina impactan fundamentalmente en las capacidades operativas, la capacidad del espacio de trabajo y los niveles de precisión alcanzables. Los dos enfoques arquitectónicos principales (diseños de mesa giratoria y cabezal giratorio) ofrecen ventajas complementarias para diferentes requisitos de fabricación.

| Tipo de configuración | Ejes rotacionales | Ventajas principales | Aplicaciones óptimas | Precisión típica |

|---|---|---|---|---|

| Mesa de muñones | Eje A (inclinación de la mesa) + Eje C (rotación) | Rigidez de husillo fija, capacidad para piezas de trabajo pesadas (300 kg+), estabilidad térmica | Grandes componentes aeroespaciales, carcasas de transmisión de automóviles, moldes pesados | ±0,005 mm lineal, ±10″ rotacional |

| Cabezal giratorio | Eje A (inclinación de la cabeza) + Eje B (rotación de la cabeza) | Fijación simplificada, alcance extendido del eje Z, tamaño compacto | Implantes médicos, fabricación de herramientas de corte, moldes de precisión | ±0,003 mm lineal, ±5″ rotacional |

| Orientación vertical | Varios (B+C común) | Evacuación de viruta asistida por gravedad, accesibilidad del operador, especialización en piezas pequeñas | Componentes electrónicos, insertos de herramientas de corte, herramientas de joyería | ±0,003 mm lineal, ±5″ rotacional |

| Orientación horizontal | Varios (A+C común) | Mayor volumen de trabajo, compatibilidad con automatización de paletas dobles, estabilidad de corte pesado | Bloques de motor de automoción, componentes estructurales de gran tamaño, mecanizado de producción | ±0,005 mm lineal, ±10″ rotacional |

Los diseños de mesa Trunnion posicionan la capacidad de rotación dentro del conjunto de la mesa de trabajo, con un eje A que proporciona movimiento de inclinación y un eje C que permite la rotación completa. La configuración de husillo vertical fijo proporciona una rigidez excepcional, ya que las fuerzas de corte se transmiten directamente a través de la estructura estática del husillo sin deflexión angular. Esta arquitectura destaca en aplicaciones que requieren altas tasas de extracción de material o el procesamiento de componentes grandes donde la masa de la pieza (hasta 300 kg) supera los límites prácticos de las configuraciones de cabezal móvil.

Las configuraciones de cabezal giratorio permiten montar el cabezal del husillo articulado en los ejes de rotación A y B, manteniendo la mesa de trabajo fija durante toda la operación. Esta disposición simplifica el diseño de utillajes, ya que los sistemas de sujeción no requieren compatibilidad rotacional. El tamaño compacto de la máquina —ejemplificado por los sistemas verticales de 5 ejes de OPMT, que ocupan una superficie de 2,3 m × 1,8 m— hace que los diseños de cabezal giratorio sean ideales para instalaciones con una superficie de producción limitada.

La selección de la orientación vertical u horizontal depende principalmente de las características de la pieza y los requisitos de producción. Los sistemas verticales de 5 ejes, como la configuración OPMT 563V, optimizan la evacuación de virutas mediante la asistencia por gravedad, evitando su acumulación en las zonas de corte durante el procesamiento de piezas pequeñas (diámetro máximo de 200 mm). Las orientaciones horizontales aumentan el volumen de trabajo accesible, permitiendo piezas de hasta 800 mm de longitud, a la vez que mantienen la compatibilidad con sistemas de automatización de doble palé para la fabricación sin intervención del operador.

Los factores de selección de configuración van más allá de la capacidad geométrica e incluyen los requisitos de par, la gestión térmica y la integración con sistemas auxiliares. Las operaciones de fabricación de herramientas de corte que procesan materiales de carburo y PCD se benefician de configuraciones verticales compactas con husillos de alta velocidad (más de 15 000 rpm), mientras que el mecanizado de componentes estructurales aeroespaciales requiere sistemas horizontales que proporcionen un par de husillo superior a 200 N⋅m a bajas rpm para el procesamiento de titanio.

Las operaciones de cinco ejes específicas de la industria demuestran el impacto de la tecnología en los sectores de fabricación de alta precisión, cada uno de los cuales presenta requisitos técnicos y estándares de rendimiento únicos.

Las operaciones de perforación aeroespacial aprovechan las capacidades simultáneas de 5 ejes para ejecutar conductos de refrigeración de ángulo compuesto en álabes de turbina de titanio. Estos canales internos siguen trayectorias tridimensionales complejas diseñadas para maximizar la eficiencia de la transferencia térmica, lo que requiere operaciones de perforación que mantengan una tolerancia angular de ±0,5° y alcancen una precisión posicional de 0,05 mm a profundidades superiores a 100 mm. La interpolación continua de ejes evita las discontinuidades geométricas que comprometerían la eficiencia de la refrigeración y crearían puntos de concentración de tensiones que provocarían fallos prematuros en los componentes. Los sistemas avanzados integran la monitorización del proceso en tiempo real para detectar la deflexión de la herramienta, compensando automáticamente la recuperación elástica característica de las aleaciones de titanio aeroespaciales.

La fabricación de dispositivos médicos emplea operaciones de 5 ejes para el microperforado de implantes cerámicos con relaciones profundidad-anchura extremas que alcanzan 100:1. Los vástagos femorales de los implantes de cadera requieren canales de drenaje de 0,5 mm de diámetro que se extienden 50 mm a través de cerámica densa de alúmina o zirconio. El perforado mecánico tradicional genera microfisuras que se propagan durante la vida útil del implante, mientras que sistemas láser de femtosegundo de 5 ejes Logre una ablación sin grietas mediante pulsos ultracortos que evitan la difusión térmica al material circundante. La configuración Micro3D L570V de OPMT ofrece estas capacidades con una precisión de posicionamiento de 0,003 mm en su área de trabajo de 5 ejes.

La producción de herramientas de corte para automoción representa una aplicación de alto volumen que requiere una repetibilidad excepcional. El procesamiento de fresas de PCD y CBN alcanza una precisión dimensional de 0,003 mm con una estabilidad de tolerancia de 0,001 mm en lotes de producción superiores a 10 000 piezas. La serie OPMT Light 5X demuestra esta capacidad mediante el procesamiento láser integrado que sustituye al rectificado convencional, reduciendo los tiempos de ciclo de 45 minutos por fresa (método EDM) a 15 minutos (método láser), a la vez que mejora la consistencia del filo. Esta reducción del tiempo de ciclo del 66% repercute directamente en la rentabilidad de la fabricación en la producción de herramientas para automoción de alto volumen.

El mecanizado de herramientas de corte de precisión amplía las capacidades de 5 ejes a la creación de características internas, en concreto a los canales de suministro de refrigerante que mantienen un diámetro de 0,5-2 mm con tolerancias de rectitud de 0,05 mm en profundidades de 50 mm. Estos sistemas de refrigeración a través de la herramienta requieren una interpolación continua de 5 ejes para seguir trayectorias helicoidales que optimizan el suministro de fluido de corte a la interfaz herramienta-pieza. El desafío se intensifica al procesar sustratos de carburo con valores de dureza superiores a 1500 HV, donde el taladrado mecánico provoca daños subsuperficiales que comprometen la vida útil de la herramienta.

La integración híbrida láser-CNC de OPMT permite el procesamiento en frío de materiales superduros en configuraciones de 5 ejes, combinando la ablación láser de femtosegundos para operaciones de desbaste con el acabado mecánico para tolerancias finales. Este enfoque híbrido procesa materiales que antes se consideraban no mecanizables mediante métodos convencionales, como piezas brutas de diamante CVD e insertos de corte de nitruro de boro cúbico policristalino. La duración ultrarrápida del pulso láser (100 femtosegundos) previene las zonas de daño térmico, mientras que el control de movimiento de 5 ejes mantiene la precisión dimensional en geometrías complejas. Integración con máquinas láser industriales Proporciona soluciones llave en mano que combinan capacidades de procesamiento mecánico y láser dentro de entornos de trabajo unificados.

Las operaciones de corte de 5 ejes transforman radicalmente la fabricación de precisión mediante modos de posicionamiento simultáneo e indexado, cada uno optimizado para requisitos geométricos y escenarios de producción específicos. Una implementación exitosa requiere un modo operativo compatible (simultáneo para superficies esculpidas, indexado para características planas) con la configuración de máquina adecuada según las características de la pieza y las especificaciones de precisión. Los sectores aeroespacial, de dispositivos médicos y automotriz demuestran mejoras de rendimiento mensurables, incluyendo la reducción del tiempo de configuración del 65%, precisión de posicionamiento submicrónica y mejoras en el tiempo de ciclo que superan al 60% en comparación con el procesamiento convencional de 3 ejes con múltiples configuraciones.

Los ingenieros de fabricación que implementan estrategias de 5 ejes deben priorizar tres acciones: evaluar la complejidad de la geometría de la pieza para determinar los requisitos operativos simultáneos e indexados, evaluar la compatibilidad de la configuración de la máquina con los parámetros de tamaño y peso de la pieza, e integrar sistemas de monitorización de procesos para mantener las tolerancias ajustadas que permiten estas operaciones. Para obtener una guía completa sobre la selección e implementación de sistemas de 5 ejes, consulte recursos especializados que abordan... Tecnología láser vs métodos tradicionales comprender las ventajas del procesamiento híbrido disponibles en las modernas plataformas multieje.

La continua evolución de las operaciones de 5 ejes, en particular mediante la integración láser-CNC para el procesamiento de materiales superduros, amplía las capacidades de fabricación a aplicaciones anteriormente inaccesibles. Las organizaciones que invierten en estos avanzados sistemas multieje se posicionan para aprovechar oportunidades de producción de alto valor que requieren la libertad geométrica y la precisión que definen la ventaja competitiva en los mercados aeroespacial, médico y de herramientas de precisión.

Descargo de responsabilidad

Este contenido es compilado por OPMT Laser con base en información pública disponible únicamente como referencia; las menciones de marcas y productos de terceros son para comparación objetiva y no implican ninguna asociación o respaldo comercial.

Explore el mundo del mecanizado CNC mientras comparamos las tecnologías de 3 y 5 ejes. Desde operaciones básicas hasta geometrías complejas, descubra qué máquina se adapta a sus necesidades de fabricación en 2025.

Explore el probado proceso ODM de 5 fases de OPMT para sistemas láser personalizados. Fabricación con certificación ISO, precisión de ±0,003 mm y protección IP. Envíe los requisitos de su proyecto hoy mismo.

¿Está buscando los mejores proveedores de centros de mecanizado CNC de 5 ejes? ¡Consulte nuestra lista de los 10 mejores para obtener información de expertos y encontrar el que mejor se adapte a sus necesidades!

Explore las 10 mejores máquinas de corte de metales por láser de 2025, con líderes de la industria como Trumpf, Bystronic y OPMT Laser. Compare la tecnología de vanguardia, la precisión y la eficiencia para encontrar la solución perfecta para sus necesidades de fabricación.

Por favor, rellene sus datos de contacto para descargar el PDF.