Programar una visita

Independientemente de si necesita asesoramiento general o apoyo específico, estaremos encantados de ayudarle.

Independientemente de si necesita asesoramiento general o apoyo específico, estaremos encantados de ayudarle.

Todas las noticias

Compartir

El zafiro se ha convertido en un material de grado óptico preferido en la electrónica de consumo gracias a su excepcional resistencia al rayado y alta transmisión. Sin embargo, estas ventajas conllevan complejidad en su fabricación. Su extrema dureza y su comportamiento frágil a la fractura hacen que el corte y la perforación mecánicos sean sensibles a daños subsuperficiales, astillado de bordes y agrietamiento impredecible. En la producción, el factor decisivo rara vez reside en si el zafiro... poder se puede mecanizar; se trata de si un proceso puede alcanzar repetidamente objetivos dimensionales y de calidad de borde ajustados en un tiempo de actividad industrial sin introducir defectos latentes que solo aparecen después del recubrimiento, la unión o el ciclo térmico.

Por lo tanto, es necesario definir una solución láser de zafiro completa a nivel de sistema de fabricación. No se trata solo de elegir la fuente láser; es una combinación de ingeniería de régimen de pulsos, emisión del haz, control de movimiento de cinco ejes y disciplina de inspección que, en conjunto, controlan la entrada de calor, la distribución de tensiones y la geometría. Cuando estas capas se diseñan de forma coherente, el procesamiento láser se convierte en una ruta escalable para el corte y la perforación de zafiro —desde la singularización de obleas hasta los microagujeros para módulos de cámara—, a la vez que reduce la necesidad de retrabajo y estabiliza el rendimiento.

Los modos de fallo en el mecanizado de zafiro se ven dominados por la mecánica de fractura, no solo por la velocidad de arranque de material. Las microfisuras y el desportillado en los bordes se vuelven críticos porque el zafiro no se deforma plásticamente para aliviar la tensión, sino que la almacena y libera mediante fractura frágil. Por ello, dos piezas con las mismas medidas pueden comportarse de forma muy diferente posteriormente: la pieza con mayor daño subsuperficial tiene una probabilidad mucho mayor de fallar durante la presión de montaje, la limpieza ultrasónica o la vibración de campo.

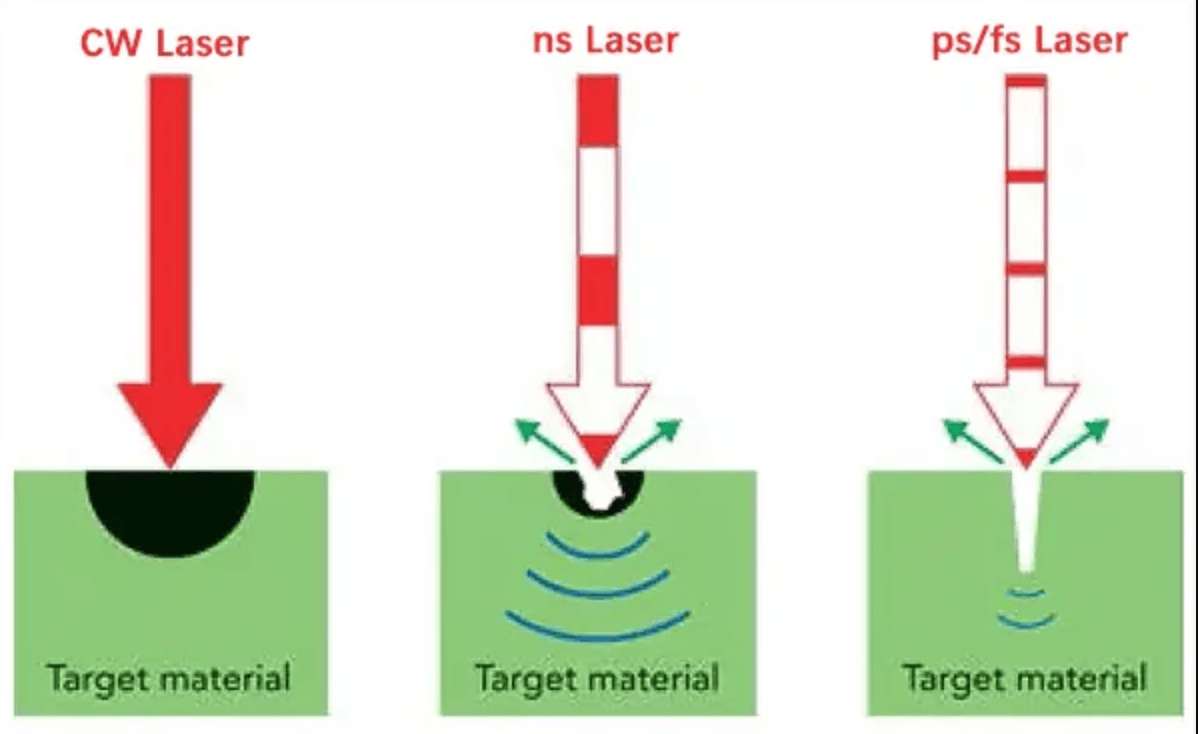

El mecanizado láser mitiga estos riesgos solo si se controlan la difusión y el choque térmico. Se prefieren los pulsos ultrarrápidos porque depositan energía en escalas de tiempo lo suficientemente cortas como para reducir el tamaño de la zona afectada por el calor (ZAC) y minimizar el crecimiento de grietas provocado térmicamente. Paralelamente, la estabilidad del proceso depende en gran medida de la consistencia con la que el sistema mantiene la fluencia en la superficie de trabajo, un aspecto que se relaciona tanto con la dinámica del movimiento y el control focal como con el propio láser.

En las fábricas de electrónica reales, los programas de zafiro normalmente se dividen en dos rutas de ingeniería:

No se trata de una decisión excluyente; muchas líneas consolidadas implementan ambas. El enfoque práctico consiste en asignar cada familia de características a la ruta con la ventana de proceso más amplia: femtosegundos para bordes sensibles a grietas y microcaracterísticas de precisión, y guiado por agua para corte profundo, donde el enfriamiento continuo suprime el daño térmico.

El corte por ablación es el método más flexible para formas libres de zafiro (ventanas de cubiertas de cámaras, aperturas de relojes, ventanas de sensores irregulares), ya que se trata fundamentalmente de un problema de trayectoria de la herramienta, no de geometría de la cuchilla. El principal reto de producción reside en evitar el sobrecalentamiento local en los puntos de inicio y fin y en radios estrechos. En la práctica, las recetas estables se basan en estrategias de multipasada superficial, superposición controlada y un movimiento que mantiene la incidencia y el enfoque del haz constantes a lo largo del contorno.

Para los equipos de ingeniería que evalúan la capacidad de los equipos para este estilo de corte, es fundamental verificar si la plataforma puede mantener la precisión al ejecutar trayectorias complejas de cinco ejes a gran velocidad. Por ejemplo, Centro de mecanizado láser de femtosegundos de cinco ejes Micro3D L530V de OPMT Se especifica con recorridos X/Y/Z de 300/300/260 mm, eje B ±120° y eje C 360°, y proporciona una precisión de posicionamiento de eje publicada de 0,003 mm (repetición 0,002 mm) y una precisión de posicionamiento B/C de 5″ (repetición 3″). Estos valores cinemáticos y de precisión publicados son de gran importancia en el zafiro, ya que determinan si el proceso puede mantener una colocación de puntos constante y una calidad de borde uniforme durante largos ciclos de producción y con múltiples accesorios.

El troceado sigiloso se utiliza comúnmente para la singulación de zafiro a nivel de oblea, donde se debe minimizar la pérdida de ranura y la integridad de la superficie es fundamental. Este método crea una capa interna modificada, tras la cual la separación controlada produce una división limpia con menor daño superficial. En la producción de alto rendimiento, el troceado sigiloso se centra menos en la potencia y más en la consistencia de la colocación del foco, la manipulación de las obleas y el control de la separación, elementos que deben integrarse en toda la línea (alineación, sujeción e inspección en línea).

El corte láser guiado por agua no es simplemente "láser más agua"; es un sistema óptico y de fluidos acoplado que modifica la física térmica del mecanizado. OPMT describe este enfoque como el confinamiento del láser pulsado mediante reflexión interna total en una corriente de agua de 50 µm, mientras que el chorro de agua desionizada enfría la zona de corte para suprimir la ZAT por debajo de 5 µm. En el corte de zafiro, este efecto de enfriamiento puede marcar la diferencia entre un borde visualmente aceptable y uno con redes de microfisuras que posteriormente se propagan durante el ensamblaje.

Desde el punto de vista de la ingeniería de producción, el corte guiado por agua se suele seleccionar para ventanas de zafiro gruesas o perfiles profundos, donde la ablación en seco tiende a producir astillado de salida y concentración de tensiones térmicas. OPMT también afirma que, en más de 50 instalaciones en los sectores de semiconductores, aeroespacial y médico, los clientes lograron una reducción de entre 25 y 30% en la chatarra y un aumento de 15% en la producción en seis meses; cifras especialmente relevantes cuando el rendimiento del zafiro se ve limitado por defectos en los bordes, en lugar de por la velocidad de corte bruta.

La perforación de zafiro en electrónica suele estar condicionada por los requisitos de microagujeros: aberturas para módulos de cámara, ventanas de sensores, puertos acústicos y orificios de alineación. El verdadero objetivo de fabricación no es solo controlar el diámetro, sino también la conicidad, el astillado de los bordes y los daños subsuperficiales para que el orificio se mantenga estable durante la limpieza, el recubrimiento, el ajuste a presión y los ciclos térmicos.

Las estrategias de perforación estable tienden a dividirse en tres familias:

En la perforación guiada por agua, el chorro de agua elimina continuamente los residuos y extrae el calor residual entre pulsos, por lo que los equipos de ingeniería suelen ver una ventana de proceso más amplia para microagujeros profundos. La descripción de la tecnología láser guiada por agua de OPMT enfatiza las ranuras sin rebabas y la precisión micrométrica, y proporciona un modelo de implementación práctico (preparación del sitio, instalación, capacitación y validación) coherente con la puesta en marcha de las líneas de fabricación reguladas y de alta confiabilidad.

La optimización del proceso de zafiro es más eficaz cuando se trata como un problema de suministro de energía controlada:

En cuanto a los equipos, los ingenieros deben insistir en las especificaciones publicadas que permitan un suministro de energía estable. Por ejemplo, el Micro3D L530V se describe como una arquitectura láser de femtosegundos totalmente de fibra con un ancho de pulso ≤ 400 fs y una frecuencia de repetición ≥ 1 MHz, y está diseñado para las necesidades de producción industrial 7x24. Estas capacidades de pulso y repetición publicadas constituyen la base para desarrollar una receta robusta de ablación/perforación de zafiro antes del refinamiento del DOE.

Los criterios de aceptación del zafiro en la fabricación de productos electrónicos suelen estructurarse en torno a tres resultados mensurables:

La clave para la estabilidad de la producción reside en que la inspección sea procesable. Esto implica vincular los resultados medidos con parámetros controlables: superposición, desplazamiento del enfoque, estrategia de la trayectoria de la herramienta y (para el procesamiento guiado por agua) estabilidad del chorro de agua y estado de la boquilla. Por lo tanto, el plan de inspección debe incluir tanto la metrología del producto (filo/desconchado/rugosidad) como las comprobaciones del estado del proceso (alineación, limpieza de la boquilla, estabilidad del chorro y control de versiones de la receta).

Cuando las organizaciones operan bajo sistemas de calidad formales, especialmente en las cadenas de suministro médicas o aeroespaciales, la documentación se convierte en parte integral del rendimiento de la fabricación. OPMT afirma explícitamente que su proceso láser guiado por agua cumple con las normas ISO 9001:2015 y FDA 21 CFR 820, lo que se alinea con la realidad de que la validación y la trazabilidad del proceso suelen ser obligatorias cuando se utilizan componentes de zafiro en ensamblajes regulados.

Una plataforma láser compatible con zafiro debe evaluarse como una máquina herramienta, no como una simple máquina láser. En la práctica, los factores diferenciadores más significativos son:

La descripción de la Micro3D L530V indica motores lineales en los ejes X/Y/Z y motores de par en los ejes B/C, con control de lazo cerrado en los ejes lineal y rotatorio para una respuesta dinámica rápida. En el caso del zafiro, esta arquitectura de control afecta directamente la suavidad del contorno, la consistencia de los bordes y la capacidad de mantener una ventana de proceso estable durante ciclos largos y operaciones de varios turnos.

Las líneas de láser de zafiro tienen éxito cuando la puesta en marcha se considera un proyecto de fabricación en lugar de un experimento de laboratorio. Un plan de implementación práctico incluye:

OPMT ofrece un modelo de implementación por fases específico para la implementación de láseres guiados por agua: de 4 a 6 semanas de preparación del sitio, 2 semanas de instalación, 1 semana de capacitación y de 2 a 4 semanas de validación. Este ritmo es coherente con la forma en que las fábricas suelen minimizar los riesgos de la puesta en marcha del proceso, manteniendo al mismo tiempo los plazos de lanzamiento de los programas de electrónica de consumo.

El láser suele superar económicamente al mecanizado mecánico con zafiro cuando el cuello de botella actual es el rendimiento (residuos/retrabajo) o los pasos de acabado, no solo el tiempo de ciclo. El argumento comercial más defendible cuantifica:

Dado que los programas de zafiro varían considerablemente en cuanto a grosor, geometría y criterios de borde, el enfoque más fiable es ejecutar un piloto estructurado con sus métricas de aceptación exactas y luego traducir los deltas validados en ROI. Cuando el piloto se basa en la capacidad de la máquina publicada y en un plan de implementación documentado, el riesgo de ampliación se reduce drásticamente.

Compare sistemas láser de picosegundos y nanosegundos para la fabricación industrial. Datos de la ZAT, velocidades de procesamiento, análisis de costos y criterios de aplicación de los sistemas implementados por OPMT.

Las máquinas de corte láser PCD ofrecen una precisión de 0,003 mm y un procesamiento tres veces más rápido que la electroerosión. Guía técnica completa para la fabricación de herramientas de diamante policristalino para las industrias aeroespacial y automotriz.

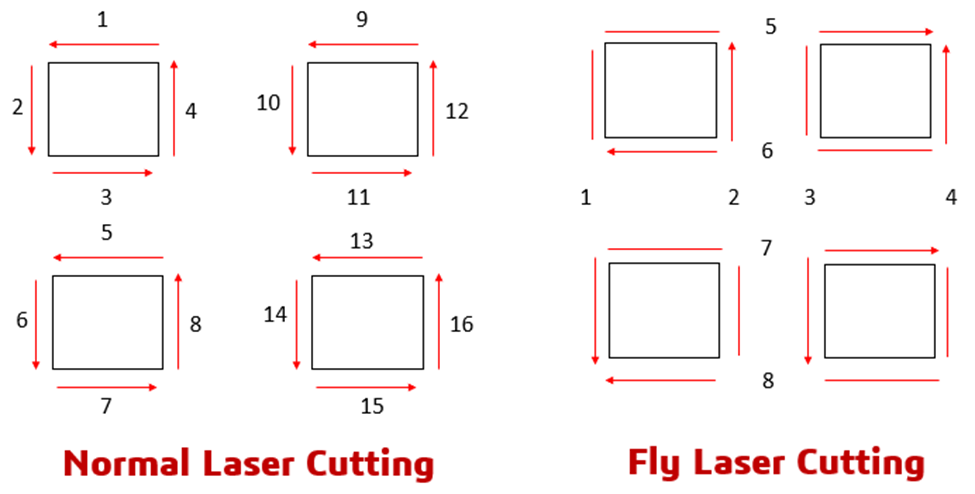

La tecnología láser de corte al vuelo reduce el tiempo de ciclo en un 30-50% mediante la optimización continua de la trayectoria de movimiento. Aprenda la mecánica, las aplicaciones y las especificaciones de los equipos OPMT para la fabricación de precisión.

Marcos de evaluación de fábricas para la adquisición de equipos de corte láser. Evaluación de infraestructura, análisis de sistemas de calidad y cálculo del coste total de propiedad (CTP) basado en más de 30 auditorías de instalaciones.

Por favor, rellene sus datos de contacto para descargar el PDF.