Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

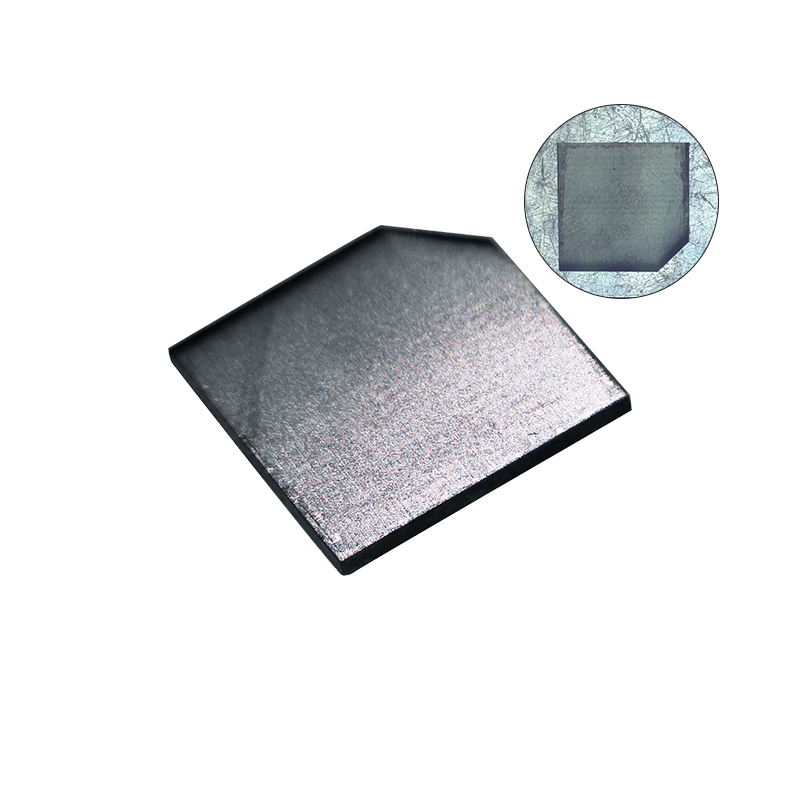

The synthetic diamond manufacturing industry is experiencing transformative growth, with global market valuations projected to exceed $29.5 billion by 2029. Manufacturing engineers and precision machining specialists increasingly require comprehensive understanding of Chemical Vapor Deposition (CVD) and High-Pressure High-Temperature (HPHT) diamond processing methodologies, particularly when implementing advanced laser machining systems. This technical guide examines both synthesis approaches through the lens of downstream laser processing requirements, providing actionable insights for optimizing manufacturing operations and achieving superior quality outcomes.

Key Technical Insight: Comprehensive analysis of industrial implementations demonstrates that laser processing parameters must be specifically calibrated for each diamond type, with ultrafast laser systems delivering documented improvements in processing efficiency and quality consistency compared to conventional machining methods.

CVD diamond synthesis represents a sophisticated materials engineering process that deposits carbon atoms onto substrates through carefully controlled plasma-enhanced chemical reactions. This methodology operates under precisely maintained environmental conditions that enable the production of high-purity diamond crystals with exceptional optical and mechanical properties.

The CVD process requires controlled atmospheric conditions compliant with ISO 14644-1 standards for contamination control. Manufacturing facilities must maintain strict environmental controls to ensure consistent crystal quality and structural integrity throughout the growth cycle.

Critical Process Parameters:

CVD methodology enables production of Type IIa diamond crystals with nitrogen concentrations below 1 ppm, achieving optical transparency exceeding 99.5% across visible spectrum wavelengths. These characteristics make CVD diamonds particularly suitable for precision optical applications and advanced laser cutting technology applications.

HPHT synthesis replicates geological diamond formation through precisely controlled thermodynamic conditions utilizing belt-type, cubic anvil, or split-sphere press configurations. These systems must comply with established pressure vessel safety requirements to ensure operator safety and equipment reliability.

The HPHT process subjects diamond seeds to extreme pressures exceeding 5 GPa while maintaining temperatures of 1,400-1,600°C in the presence of metal catalysts. This approach produces diamonds with distinct structural characteristics that significantly impact subsequent laser processing parameters and quality outcomes.

Engineering Specifications:

HPHT diamonds frequently incorporate metallic inclusions from catalyst materials, resulting in Type Ib classification with nitrogen concentrations of 50-500 ppm. These inclusions significantly impact electrical conductivity and require specialized laser processing approaches to achieve optimal results.

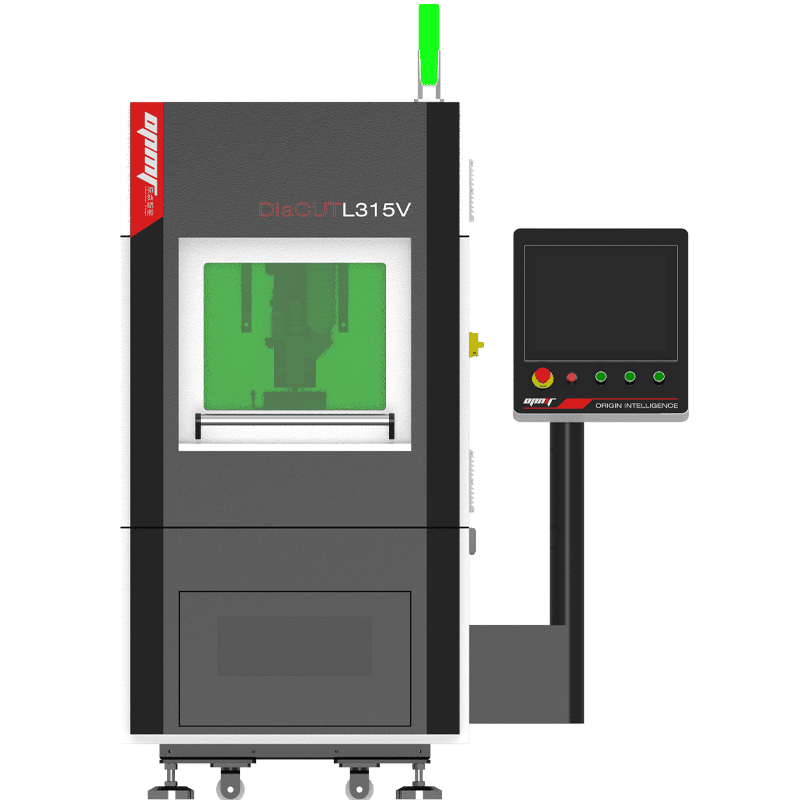

Modern diamond processing demands sophisticated laser systems capable of delivering precise energy control while minimizing thermal effects. Ultrafast laser technology represents current state-of-the-art methodology for achieving superior edge quality and dimensional accuracy in synthetic diamond materials.

Femtosecond Laser Parameters:

Picosecond Laser Configurations:

These specifications enable manufacturers to achieve exceptional precision while maintaining the structural integrity of processed diamond components. The selection between femtosecond and picosecond systems depends on specific application requirements and desired surface quality characteristics.

Our 5-axis laser machining systems provide industry-leading performance for diamond processing applications:

| Performance Metric | Specification | Standard Compliance |

|---|---|---|

| Positioning Accuracy | ±2 μm | ISO 230-2:2014 |

| Repeatability | ±1 μm | Statistical process control |

| Angular Accuracy | ±5 arcseconds | Multi-axis calibration |

| Maximum Feed Rate | 30 m/min | High-speed machining |

| Acceleration Capability | Up to 2G | Dynamic performance |

| Spindle Speed Range | 0-60,000 RPM | Variable speed control |

| RTCP Technology | Real-time compensation | Advanced motion control |

The integration of Real-Time Tool Center Point (RTCP) technology ensures consistent processing quality regardless of workpiece orientation or complex geometric requirements. This capability is essential for achieving the dimensional tolerances demanded in high-precision diamond component manufacturing.

CVD diamonds require specialized processing approaches due to their unique structural characteristics and thermal properties. The columnar growth pattern typical of CVD synthesis creates directional properties that must be considered when developing laser processing parameters.

Optimal Processing Conditions:

CVD diamonds’ non-conductive properties render traditional EDM methods ineffective, making laser processing the preferred approach for achieving precision geometries. The absence of metallic inclusions allows for consistent processing results across the entire workpiece volume.

HPHT diamonds present unique processing challenges due to their metallic inclusions and variable electrical conductivity. These characteristics require modified laser parameters and enhanced quality monitoring protocols to ensure consistent results.

Processing Parameter Adjustments:

The presence of metallic inclusions necessitates careful parameter selection to avoid localized heating effects that could compromise surface quality or dimensional accuracy. Advanced multi-axis processing systems provide the flexibility required to optimize processing paths around inclusion zones.

Based on validated customer implementations, laser processing technology demonstrates measurable advantages over conventional processing methods:

| Processing Aspect | Traditional Methods | OPMT Laser Processing | Performance Improvement |

|---|---|---|---|

| Processing Speed | Baseline reference | Up to 3.0× faster | 200% speed increase |

| Edge Quality | Variable results | Consistent clean edges | Superior surface integrity |

| Non-Conductive Materials | Limited capability | Complete processing flexibility | 100% material compatibility |

| Floor Space Requirement | 10m² footprint | 6m² footprint | 40% space reduction |

| Energy Consumption | 4.5 kWh/hour | 2.5 kWh/hour | 44% energy savings |

Monthly Operating Cost Comparison (Based on standard 8-hour daily operation):

| Cost Category | Traditional Processing | Laser Processing | Cost Reduction |

|---|---|---|---|

| Electrical Consumption | 720 yuan | 400 yuan | 44% reduction |

| Consumable Materials | 1,280 yuan | Minimal | Significant reduction |

| Cooling/Process Fluids | 320 yuan | 80 yuan | 75% reduction |

| Facility Utilities | 800 yuan | 480 yuan | 40% reduction |

| Maintenance Supplies | 420 yuan | 336 yuan | 20% reduction |

| Total Monthly Cost | 3,540 yuan | 1,296 yuan | 63% reduction |

These documented cost reductions, combined with increased processing speeds and improved quality outcomes, demonstrate the economic advantages of laser processing technology for diamond manufacturing applications.

Successful diamond processing operations require comprehensive quality management systems that ensure consistent results and regulatory compliance. Implementation of standardized quality control procedures is essential for maintaining manufacturing excellence.

Essential Quality Control Elements:

Measurement and Verification Protocols:

Different industries require specific compliance standards that must be integrated into the manufacturing process. Medical device applications demand FDA compliance, while aerospace applications require AS9100 certification.

Medical Device Compliance Requirements:

Aerospace Industry Requirements:

Implementing successful diamond laser processing requires a methodical approach to parameter development and validation:

Phase 1: Material Characterization and Analysis

Phase 2: Parameter Development and Optimization

Phase 3: Process Validation and Documentation

Phase 4: Production Implementation and Control

Challenge: Edge Quality Consistency

Challenge: Dimensional Accuracy Control

Challenge: Processing Efficiency Optimization

The automotive sector requires precision cutting tools capable of processing advanced materials including carbon fiber composites and high-strength alloys. Laser processing enables production of specialized tools with complex geometries and superior surface quality.

Documented Performance Results:

Surgical instruments and medical devices require biocompatible surfaces with exceptional quality specifications. Laser processing provides the precision necessary to meet stringent regulatory requirements.

Critical Performance Specifications:

Diamond’s thermal conductivity properties make it ideal for heat spreader applications in power electronics. Precision laser processing enables custom thermal management solutions.

Technical Applications:

Our water-guided laser technology provides enhanced capabilities for electronics applications through superior thermal management and contamination control.

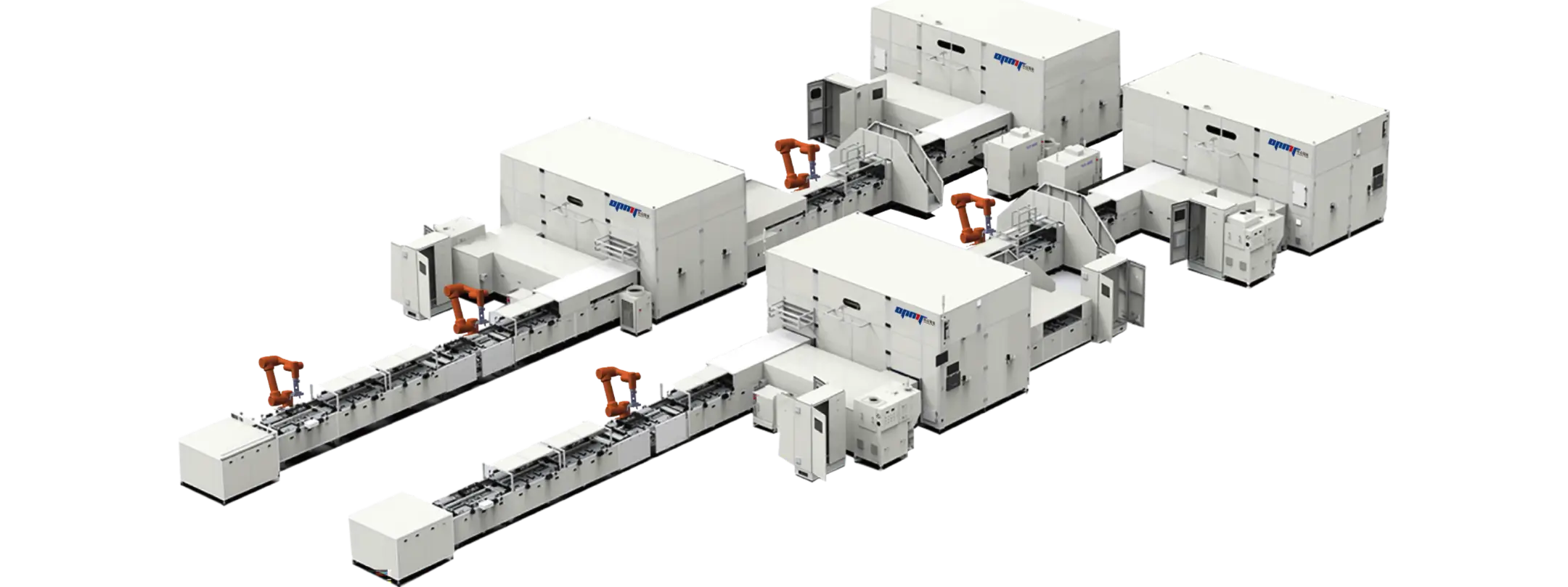

Modern laser processing incorporates sophisticated control systems enabling real-time optimization and quality assurance:

Control System Capabilities:

Implementation Architecture:

The evolution of diamond processing continues through advances in laser technology, control systems, and process understanding:

Technology Developments:

Industry 4.0 Integration:

Economic evaluation of advanced laser processing systems requires comprehensive analysis of both capital and operational costs throughout the equipment lifecycle:

Investment Components:

Performance Benefits:

Quality Risk Mitigation:

Operational Benefits:

Return on investment for advanced laser processing systems typically ranges from 8-14 months, depending on production volume, component complexity, and quality requirements.

The selection between CVD and HPHT diamond processing requires comprehensive evaluation of application requirements, quality standards, compliance needs, and economic factors. Advanced laser processing technology provides superior results for both diamond types, delivering measurable improvements in speed, quality, and cost-effectiveness while maintaining compliance with manufacturing standards.

Strategic Implementation Framework:

Implementation Pathway:

Manufacturing engineers should initiate validation programs using representative materials under actual production conditions. OPMT’s implementation services include comprehensive documentation, training programs, and technical support to ensure successful deployment and investment optimization.

Technology Roadmap:

The future of synthetic diamond manufacturing requires intelligent integration of advanced synthesis methods with precision laser processing technology. This approach enables achievement of unprecedented quality, efficiency, and sustainability levels while maintaining regulatory compliance across global markets.

Success in diamond processing implementation requires careful consideration of material characteristics, application requirements, quality standards, and economic factors. Organizations benefit from comprehensive planning, systematic validation, and continuous optimization to maximize the advantages of advanced laser processing solutions.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.