Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

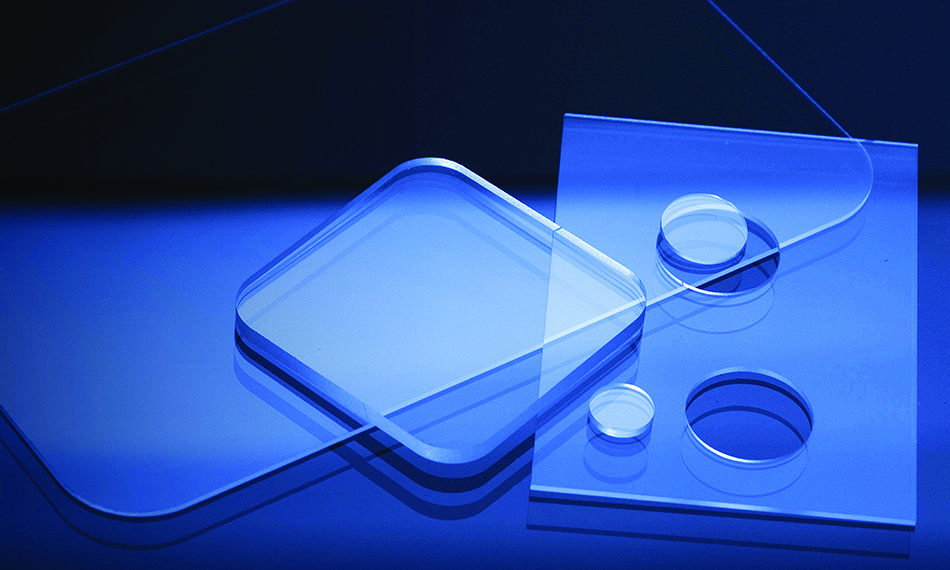

Laser cutting glass is a remarkable technique that opens up a realm of possibilities for designers and manufacturers alike. You might be aware that glass, while similar to ceramics, presents unique challenges due to its brittle nature; it can shatter easily, creating hazardous shards.

Did you know that the global laser cutting market is expected to reach $7 billion by 2026? This statistic highlights the growing demand for precision cutting technologies, including those for glass. In this article, we’ll share ten essential insights about laser cutting glass and the machines used in this process, helping you navigate its complexities and maximize your profits with OPMT Laser’s expertise.

Are you ready to enhance your understanding and unlock new opportunities in glass fabrication? Let’s get started!

Laser glass cutting is a precise method that utilizes a concentrated laser beam to melt and vaporize glass, allowing for intricate designs and shapes. This technique offers significant advantages over traditional glass cutting methods, which often involve scoring the glass and applying force to break it. With laser cutting, the laser interacts with the glass for mere milliseconds, imparting energy without causing warping or cracks. This efficiency not only enhances productivity but also ensures high-quality outcomes.

Why should industries consider laser cutting for their glass processing needs? Here are some key benefits:

Research shows that using laser technology does not compromise the material strength or thermal stability of glass, making it a reliable choice for various applications.

Laser cutting machines can be categorized based on their laser sources. Here are four prevalent types:

For businesses looking to invest in advanced laser technology, OPMT Laser offers a range of innovative CNC systems and laser processing solutions tailored to meet diverse needs. Explore products like the Micro3D-L570V or the LP550V to enhance your capabilities.

Read More: Best 10 Lab Diamond Machine Suppliers

When it comes to laser cutting, soda lime glass stands out as the most accessible option. This popular glass type is not only cost-effective but also easier to manipulate compared to borosilicate glass, which is known for its high thermal resistance. While borosilicate cannot be cut using standard laser machines, soda lime glass melts under the laser beam yet retains its structural integrity, making it ideal for various applications. Additionally, it can be tempered post-processing for enhanced thermal resistance, providing versatility in design and functionality.

Laser cutting technology dramatically outpaces traditional methods. While skilled artisans can achieve impressive results, they cannot match the speed of laser cutters. The precision of a laser cutter eliminates the risk of cracks that often occur with manual cutting techniques. With only the cutting head in motion, there are no vibrations or shocks that could compromise the glass. This allows for rapid execution of complex shapes and designs, making laser cutting an efficient choice for both small and large-scale projects.

One of the remarkable benefits of laser cutting is that it produces smooth edges without the need for post-cut sanding. Traditional methods often leave rough edges that require additional finishing work, posing safety risks. In contrast, the melting process at the edges during laser cutting creates a clean finish, enhancing both safety and efficiency in production. This feature not only saves time but also reduces labor costs associated with secondary processing.

While high-powered lasers excel in cutting metals, they can be counterproductive for glass. Excessive energy can lead to burning marks rather than clean cuts because glass reflects much of the laser energy. Instead, using lower-wattage ultraviolet (UV) lasers proves more effective in achieving precise cuts without damaging the material. Understanding the appropriate power settings is crucial for optimal results in glass cutting.

Although handheld lasers offer portability for simple shapes, they are not ideal for cutting glass sheets due to potential inaccuracies and human error. For businesses focused on precision and quality, investing in CNC glass laser cutters is far more advantageous. These machines provide consistent accuracy and reliability that handheld options cannot match, ensuring superior outcomes in glass processing.

When working with glass sheets, employing short pulses of laser energy is essential. Long exposure times can cause energy to dissipate rather than penetrate effectively. Research indicates that lasers only need to make contact with the glass for a femtosecond—one quadrillionth of a second—to achieve precise cuts. This method allows even low-power lasers to cut through thicker materials efficiently.

For most applications involving standard thicknesses (under 0.2 inches), a CO2 laser operating at 30-40W is sufficient. Higher wattages do not necessarily yield better results; instead, optimizing laser output while minimizing contact time is key. Businesses should focus on maximizing efficiency rather than investing in unnecessarily powerful machines.

Various types of lasers—including CO2, diode, and fiber—can effectively cut glass. While wattage plays a minor role in cutting functionality, selecting the right type can lead to reduced maintenance costs and improved efficiency. Fiber lasers are particularly advantageous due to their longevity and performance balance, making them an excellent choice for businesses looking to optimize their operations.

Precision in laser cutting hinges on the quality of servo motors and gear belts controlling the laser’s movement. High positional accuracy is vital; any deviation can compromise cut integrity. Investing in high-quality machinery ensures better outcomes by maintaining accuracy throughout the cutting process.

Estimating the cost of a laser cutter can be complex due to various factors such as machine type, work area size, power capacity, and after-sale services. Businesses should choose machines that align with their specific needs rather than opting for the most expensive model available. Understanding these variables will help ensure an investment that maximizes value and performance.

Laser glass cutting is a transformative technology that enhances precision and efficiency across various industries. OPMT Laser, a leader in innovative CNC systems and laser processing solutions, provides cutting-edge laser machines designed to meet the growing demand for high-quality glass products. This technology allows for intricate designs and shapes that were previously difficult to achieve, making it an invaluable tool in today’s manufacturing landscape.

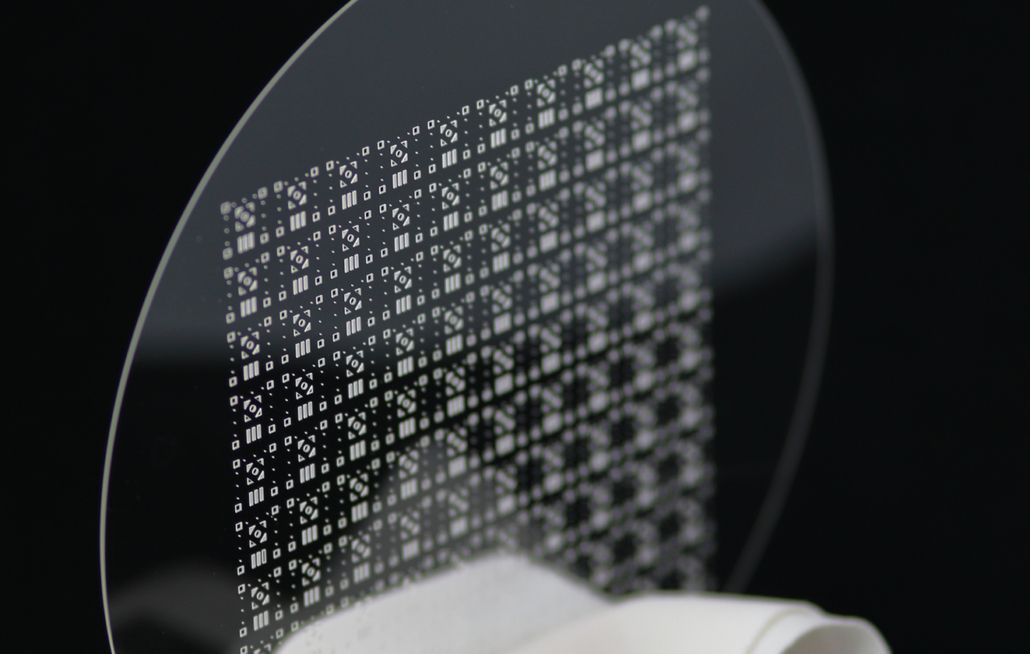

The integration of laser cutting technology has significantly improved the production of glass displays for smart devices. This method allows manufacturers to achieve millimeter precision, which is essential for creating high-quality screens for smartphones and tablets. With the increasing popularity of smart wearables, such as smartwatches and augmented reality headsets, the demand for precision-cut glass displays continues to rise. By utilizing advanced laser cutting techniques, companies can reduce production costs while maintaining lower defect rates, ultimately delivering superior products to consumers.

In the realm of microelectromechanical systems (MEMS), laser-cut glass is a critical component due to its non-conductive and corrosion-resistant properties. Thin glass sheets serve as substrates for sensitive electronic devices, ensuring reliability and performance. Laser cutting machines enable manufacturers to achieve consistent microscopic-level accuracy, which is vital for producing high-performance MEMS devices. This capability not only enhances product quality but also supports the ongoing evolution of technology in various sectors.

The medical industry relies heavily on laser-cut glass due to its inert nature, heat resistance, and ease of sterilization. Laser cutting plays a pivotal role in producing essential medical components, including microscope slides and coverslips. With OPMT Laser’s advanced solutions, healthcare providers can ensure that their equipment meets stringent standards for quality and safety. The ability to produce precise glass components quickly contributes to advancements in medical technology and patient care.

Laser cutting technology has become indispensable in the manufacturing of optical devices. From camera lenses to delicate sensors, the ability to make precise cuts in thicker glass materials is crucial. This technology not only accommodates various lens sizes but also ensures that manufacturers can meet the demanding specifications required in optical applications. By leveraging laser cutting, companies can create high-quality optical components that enhance performance across multiple industries.

Beyond cutting, laser machines offer engraving and etching capabilities that are essential for marking surfaces with important information or branding details. Unlike traditional marking methods, which may degrade over time, laser etching provides a permanent solution that withstands environmental challenges. This feature is particularly beneficial for laboratory equipment where minimal interference from external factors is crucial. With OPMT Laser’s innovative solutions, manufacturers can ensure their products are clearly marked and durable.

Selecting the right laser glass cutting machine is essential for achieving precision and efficiency in glass fabrication. Here are three critical factors to keep in mind:

Understanding the specific type of glass you will be cutting is vital. Different materials, such as tempered, borosilicate, and soda lime, each have unique requirements. For example, borosilicate and tempered glass often necessitate specialized laser operating modes to ensure optimal cutting results. When choosing a machine, consider whether it is designed to handle your specific glass types effectively. This consideration not only enhances performance but also minimizes material waste. OPMT Laser offers machines tailored for various glass materials, ensuring you find the perfect fit for your needs.

Precision is paramount in laser cutting, as it directly impacts the quality of the finished product. The quality of the motors and components in the machine plays a significant role in achieving high cutting accuracy. A well-engineered laser cutter equipped with superior rotary parts can deliver cleaner cuts and reduce errors. This level of precision is essential for applications that demand exact specifications. Investing in a high-precision laser cutting machine can lead to improved product quality and greater customer satisfaction. Explore OPMT Laser’s range of precision-focused models to find one that meets your operational standards.

When evaluating laser cutting machines, it’s crucial to understand both direct and indirect costs associated with ownership. The direct cost typically includes the purchase price and shipping fees, while indirect costs encompass maintenance, energy efficiency, and potential part replacements over time. Opting for a machine that balances initial investment with low ongoing maintenance costs can lead to significant long-term savings. OPMT Laser provides solutions designed for durability and efficiency, helping you maximize your investment while minimizing operational expenses.

By considering these factors—type of glass, cutting precision, and cost and maintenance—you can make an informed decision when selecting a laser glass cutting machine that aligns with your business needs. For more information on OPMT Laser’s innovative CNC systems and laser processing solutions, visit our product pages for detailed specifications on our offerings, such as the LP550V or the LightMut 750V.

Laser cutting glass offers remarkable benefits, including speed, precision, and ease of use. However, the unique properties of glass also present specific challenges that differ from cutting other materials like metals or wood. Understanding these intricacies can empower you to make better purchasing choices, ultimately boosting your productivity and profitability.

At OPMT Laser, we specialize in providing top-tier laser cutting solutions tailored to your needs. With over 20 years of experience and a commitment to exceptional customer service, we ensure that you receive the best training and support for your laser cutting journey.

Did you know that businesses using laser cutting technology can increase production efficiency by up to 30%? Explore our extensive range of machines and discover how OPMT Laser can elevate your operations to new heights. Ready to transform your glass cutting capabilities? Let’s get started!

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.