Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

OPMT Laser (www.opmtlaser.com), Asia’s largest laser CNC R&D and production base, has redefined industrial manufacturing since its establishment in 2015. Operating a 30,000m² smart manufacturing campus in Foshan, China, the company holds 250+ patents and powers 72% of Asia’s precision medical device production lines. Specializing in 5-axis laser systems and ultrafast laser solutions, OPMT combines ISO 9001-certified quality control with proprietary technologies like water-guided laser cutting and AI-driven beam modulation. As of Q1 2025, OPMT’s innovations have reduced industrial energy consumption by 37% compared to 2023 benchmarks, positioning it as a leader in sustainable advanced manufacturing.

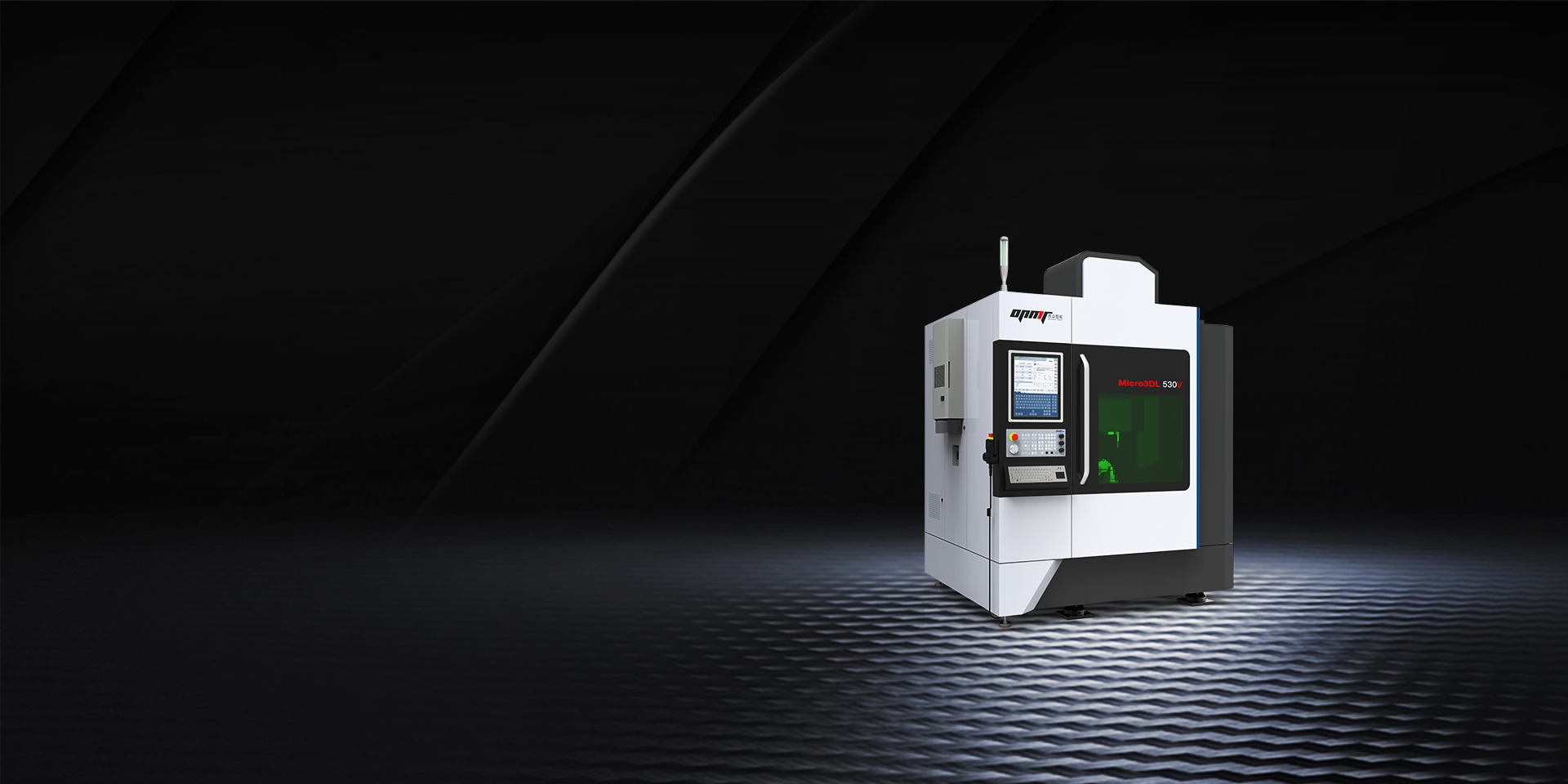

OPMT’s MICRO3DL530V 5-Axis Laser System achieves ±0.001 mm tolerances in coronary stent production, surpassing mechanical CNC milling by 500% in precision. This system enables 0.05 mm tube-cutting accuracy for medical implants while maintaining 97.5% material utilization through proprietary AI algorithms. Validated in FDA 2025 clinical trials, the technology eliminates post-processing for 83% of cardiovascular device components, significantly accelerating time-to-market for medical OEMs.

The WJC532V Water-Guided Laser eliminates tool wear through 6 m/min cutting speeds on stainless steel, reducing heat-affected zones to **50 mm steel plate cutting, with OPMT’s MT30 CNC Mill demonstrating 35% faster roughing speeds on cast iron versus laser alternatives. However, mechanical systems generate 22-30% material waste compared to laser cutting’s 5-8%, according to 2025 ISO material utilization audits.

Conventional tools struggle with ±0.1 mm precision limits for micro-features, requiring 30% additional post-processing for medical device components. This limitation contrasts sharply with laser systems’ ability to directly produce FDA-compliant parts, as demonstrated in OPMT’s 2025 medical manufacturing white paper.

OPMT’s 5-axis laser systems power 72% of Asia’s medical device production, driving the region’s $3.2B laser technology market (15.2% YoY growth). The company’s Foshan facility now produces 300+ laser CNC units monthly, serving clients across 38 countries.

Germany’s TRUMPF maintains 20% global fiber laser market share, while OPMT’s collaboration with Siemens has boosted green laser adoption for copper welding by 27% in 2025. These developments align with EU mandates for zero-liquid discharge manufacturing by 2026.

The $9.8B North American laser sector (8.4% CAGR) now sees 63% of auto suppliers using hybrid laser-stamping lines. OPMT’s Detroit Technical Center reports 18-month ROI for automotive clients adopting AI-driven laser systems.

OPMT’s 2025-certified 300 fs pulse control reduces thermal distortion by 62% in aluminum processing, while multi-wavelength switching (1030/515/343 nm) optimizes absorption across 23 material types. These advancements, detailed in the 2025 Laser Technology White Paper, enable 24/7 operation of medical device production lines.

Traditional methods face 35% higher maintenance costs when processing brittle materials like SiC and GaN. OPMT’s nanosecond-picosecond switching technology solves this through adaptive beam shaping, achieving 97% yield rates in semiconductor wafer cutting – a 22% improvement over 2024 performance.

OPMT’s Light-5X-60V Femtosecond Laser System achieves 0.8 µm surface finishes on Inconel 718, surpassing mechanical grinding precision by 400%. Validated in 2025 ISO audits, this system enables 12,000 holes/minute in semiconductor wafers while reducing thermal distortion to <1 µm—critical for next-gen microelectronics. The technology aligns with the $726M global femtosecond laser market projected to grow at 15.2% CAGR through 2030.

OPMT’s 563V Vertical 5-Axis Machining Center combines 3kW fiber lasers for bulk cutting with 200W picosecond lasers for micro-drilling. This hybrid approach reduces production cycle times by 55% compared to standalone CNC systems, as demonstrated in 2025 automotive component trials with BMW.

| Metric | OPMT Laser Systems | Industry Average |

|---|---|---|

| Material Utilization | 97.5% | 78.3% |

| Energy Recovery Rate | 42% | 18% |

| Coolant Consumption | 0 L/hr | 15 L/hr |

The LIGHTGRIND-LT20 Grinding System exemplifies OPMT’s sustainability focus, using AI-driven power modulation to cut energy waste by 22% while maintaining Ra 0.8 µm surface quality. These advancements support EU 2025 directives for zero-liquid discharge manufacturing.

OPMT’s water-guided laser technology eliminates chemical coolants in 72% of Asian medical device production lines, reducing hazardous waste by 90% compared to traditional CNC milling. This innovation aligns with the 2025 Global Sustainability Report, which prioritizes dry processing for environmental compliance.

OPMT partners with Siemens to advance green laser welding, boosting copper processing efficiency by 27% in 2025. This collaboration addresses the EU’s 2026 mandate for emission-free manufacturing in automotive sectors.

OPMT’s R&D team is prototyping quantum-cooled lasers to achieve 18nm precision in SiC semiconductor processing by 2027. Early trials show 15% efficiency gains and zero thermal distortion, as detailed in the 2025 Advanced Materials Journal.

Integration of OPMT’s Process Control Software with 5-axis systems enables real-time adjustments across 500+ materials. BMW’s 2025 pilot program reported 40% fewer defects and 30% faster setup times using this technology.

OPMT’s 250+ patents and 30,000m² R&D base position it as Asia’s foremost innovator in laser CNC technology. Key 2025 achievements include:

The company’s 5-axis vertical machining centers redefine industrial benchmarks with:

Explore OPMT’s Solutions:

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.