Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

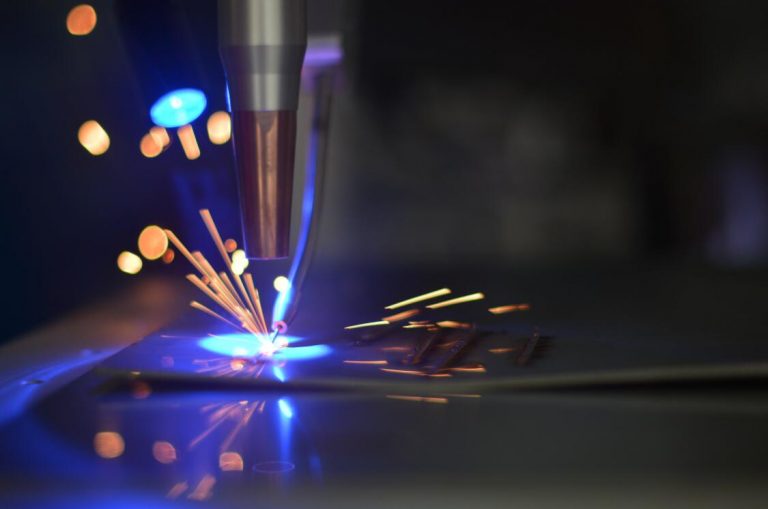

Laser Welding Machines (LWMs) stand at the forefront of welding technology, delivering unparalleled precision for industries requiring flawless welds. Proper care of these advanced tools is key to their longevity and performance. This comprehensive guide explores how LWMs function, their diverse industry applications, essential maintenance tips, and key factors for selecting the right machine. Whether you’re in aerospace, automotive, or electronics, understanding LWMs is crucial for achieving high-quality, efficient welds.

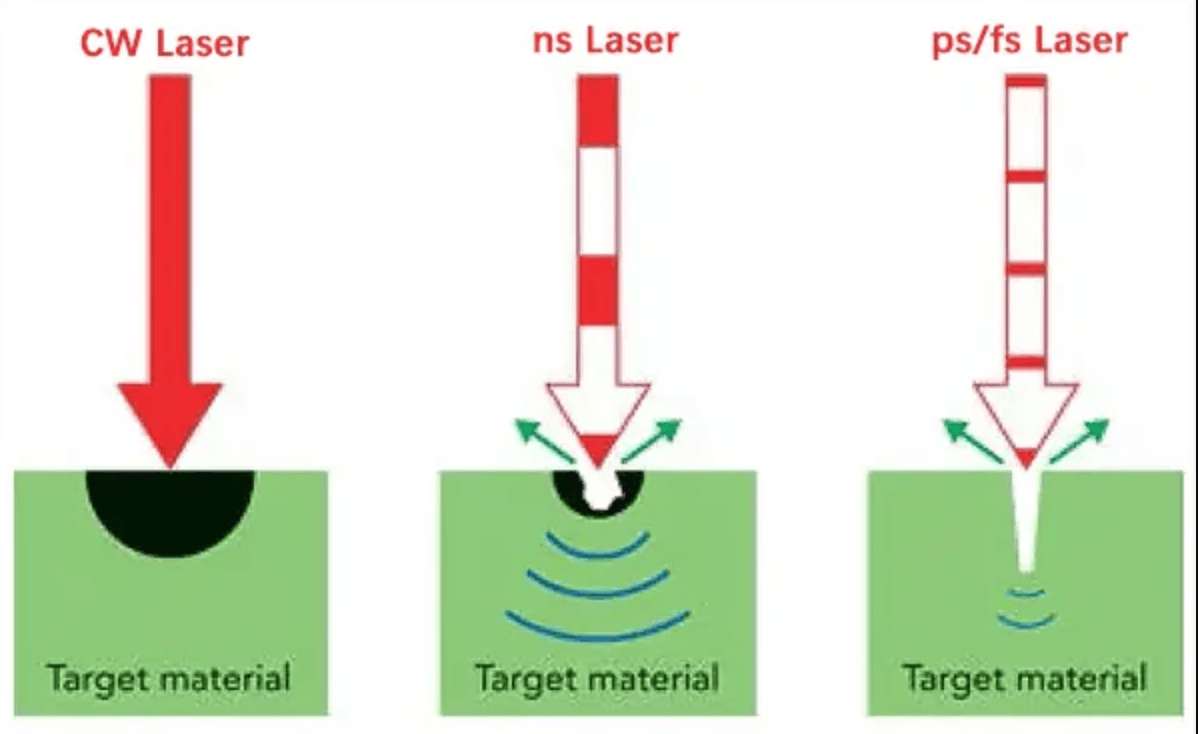

Laser welding machines utilize a focused beam of light to join materials with precision and efficiency. The process begins with a laser source, such as a fiber or CO₂ laser, generating a high-intensity beam. This beam is then directed through a series of lenses and mirrors onto the workpiece. At the point of contact, the concentrated energy creates a small, intensely hot area that melts the material. As the molten material cools, it solidifies to form a strong weld.

Key components of a laser welding machine include:

The machine’s precision allows for welding various materials, including metals and thermoplastics, with minimal distortion and high accuracy. As of 2025, advancements in laser technology have further improved energy efficiency and weld quality, making laser welding an increasingly popular choice in manufacturing industries.

Laser welding machines have become indispensable across multiple sectors, revolutionizing manufacturing processes with their unparalleled precision and versatility. Here’s a comprehensive overview of how these cutting-edge tools are transforming key industries in 2025:

Laser welding machines are reshaping automotive manufacturing:

By 2025, over 70% of luxury vehicles incorporate laser-welded components, enhancing structural integrity while reducing overall weight.

In aerospace engineering, laser welding machines are critical for:

Recent advancements have led to a 25% increase in the use of laser welding for next-generation aircraft manufacturing.

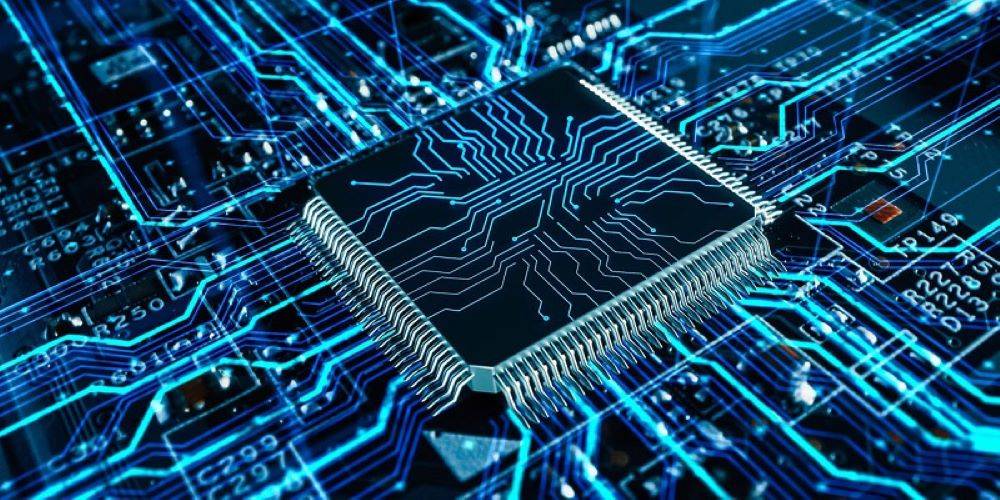

The electronics sector relies on laser welding for:

In 2025, laser welding is projected to account for 40% of all joining processes in consumer electronics production.

Laser welding machines are essential in creating life-saving medical devices:

The medical device industry has seen a 30% reduction in production costs since adopting advanced laser welding techniques.

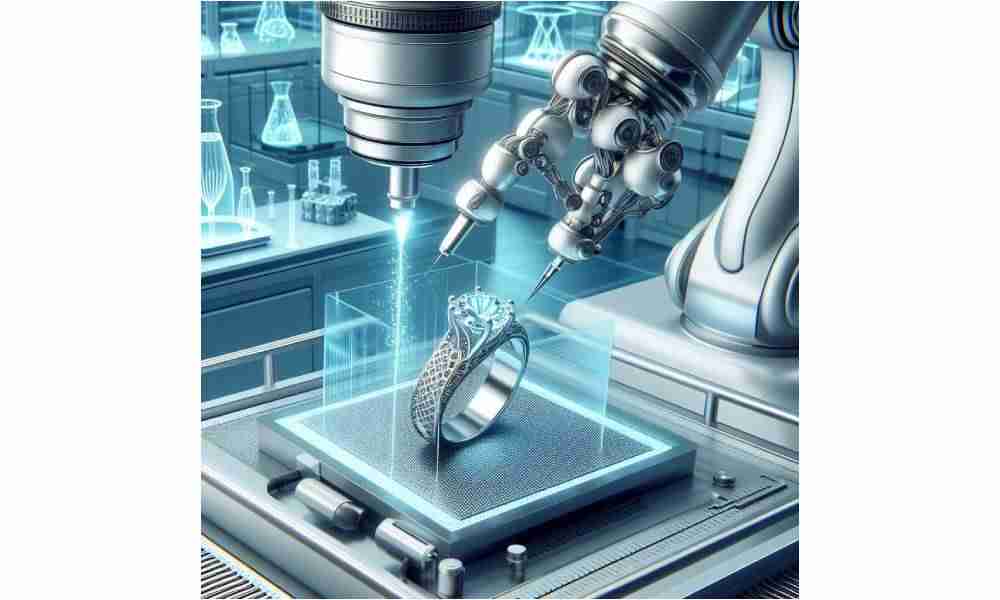

In the luxury goods sector, laser welding machines excel at:

By 2025, 80% of high-end jewelry manufacturers will use laser welding as their primary joining method.

| Industry | Key Application | Efficiency Gain |

|---|---|---|

| Automotive | Body assembly | 35% faster |

| Aerospace | Turbine parts | 50% stronger joints |

| Electronics | Battery sealing | 99.9% leak-proof |

| Medical | Implantables | 40% size reduction |

| Jewelry | Stone setting | 90% less heat damage |

Laser welding machines continue to push the boundaries of manufacturing capabilities, offering unmatched precision, speed, and versatility across industries. As technology advances, these tools are expected to play an even more crucial role in shaping the future of production processes.

Proper maintenance is crucial for optimal performance and longevity of laser welding machines. Here are key tips to keep your equipment in top condition:

Establish a strict cleaning routine to protect optical components and the laser delivery system from performance-diminishing contaminants. Use specialized lint-free wipes and manufacturer-approved cleaning solutions. Pay careful attention to optical surfaces to prevent scratches or permanent damage.

The cooling system is vital for your laser welding machine’s performance. Regular maintenance ensures optimal operating temperature and prevents overheating.

The quality of the laser beam directly correlates with the condition of the optics. Regular assessment and timely replacement of damaged components are essential.

Precision is crucial in laser welding. Regular calibration and alignment ensure consistent, high-quality welds.

Proper gas supply is critical for weld quality and machine longevity. Regular checks prevent issues related to gas flow or leaks.

Stay current with software updates to ensure optimal performance and access to the latest features.

Well-trained operators are essential for efficient machine operation and maintenance.

By implementing these maintenance tips, you can ensure consistent performance, extend the lifespan of your laser welding machine, and maintain high-quality welds throughout 2025 and beyond. Regular maintenance not only improves efficiency but also contributes to a safer working environment and reduced operational costs.

Selecting the ideal laser welding machine is crucial for maximizing efficiency and productivity in your metalworking operations. Here’s a comprehensive guide to help you make an informed decision:

Before diving into the selection process, conduct a thorough evaluation of your specific welding needs. Consider the following factors:

By thoroughly evaluating these factors, you’ll be better equipped to choose a laser welding machine that aligns perfectly with your specific requirements.

The power level and beam delivery system of your laser welding machine are critical factors that directly impact its performance and versatility. Consider the following aspects:

A well-matched combination of power and beam delivery ensures efficient welding and high-quality results across a range of materials and thicknesses.

Investing in a laser welding machine with robust maintenance support can significantly reduce downtime and extend the lifespan of your equipment. Key considerations include:

By prioritizing machines with strong maintenance support, you can minimize operational disruptions and maximize the return on your investment.

While it’s tempting to focus solely on the initial purchase price, it’s crucial to consider the total cost of ownership when selecting a laser welding machine. Factor in the following:

Aim to strike a balance between upfront costs and long-term value, choosing a machine that offers the best overall return on investment for your specific needs.

Ensure that the laser welding machine you choose is compatible with the full range of materials you work with or plan to work with in the future. Consider these points:

A versatile machine that can handle a wide range of materials will provide greater flexibility and value for your operations.

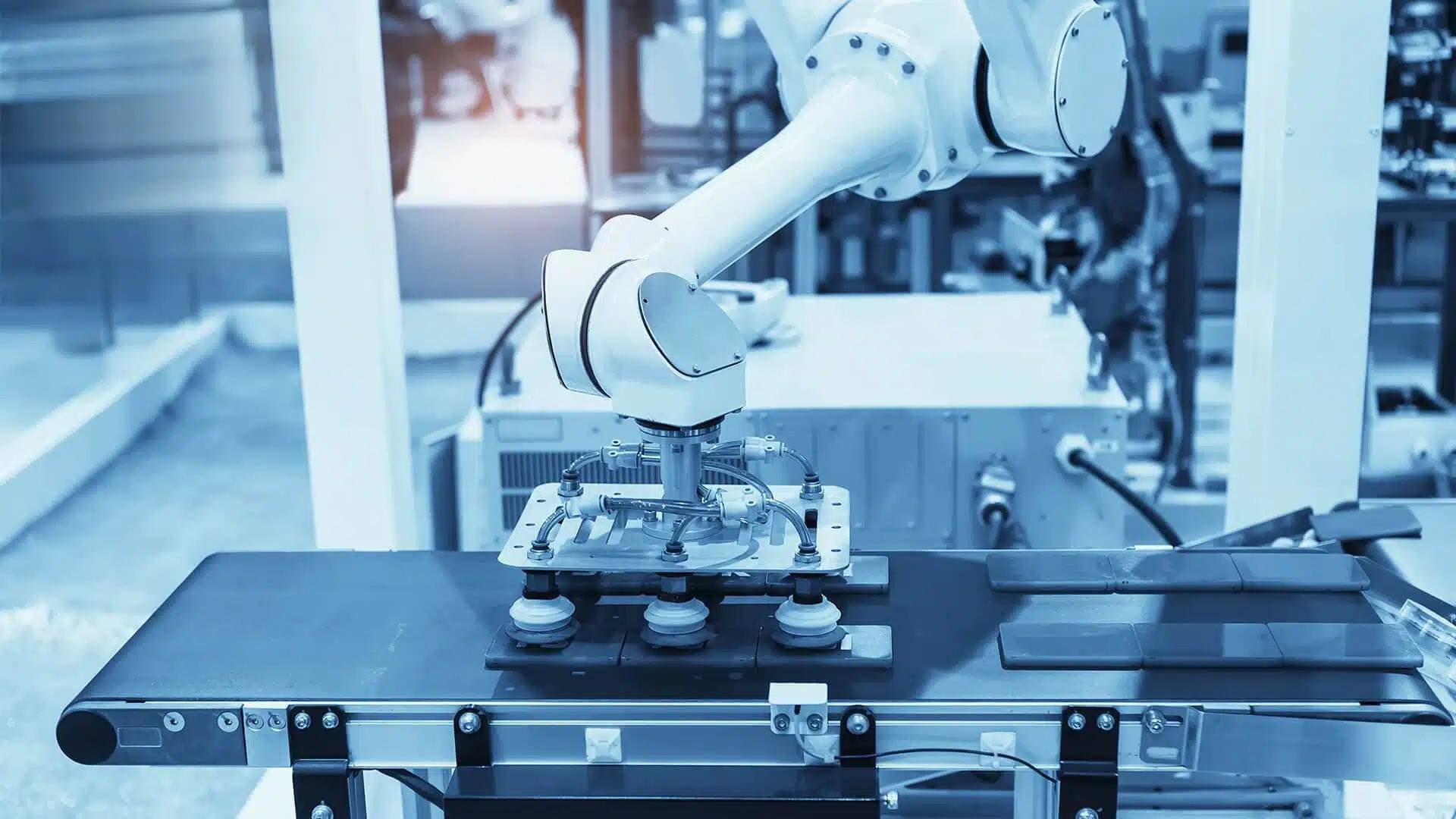

In today’s rapidly evolving manufacturing landscape, automation capabilities can significantly enhance your productivity and consistency. Look for these features:

By investing in a machine with robust automation features, you can streamline your operations and improve overall productivity.

Laser welding machines operate at high power levels, making safety a critical consideration. Ensure your chosen machine includes:

Compliance with the latest 2025 safety standards is not just a legal requirement but also crucial for protecting your workforce and maintaining a safe working environment.

By carefully evaluating these factors, you’ll be well-equipped to select a laser welding machine that aligns perfectly with your production goals, quality standards, and safety requirements. Remember that the right choice can significantly impact your operational efficiency and overall competitiveness in the metalworking industry.

Laser Welding Machines (LWMs) are revolutionizing manufacturing across diverse industries in 2025, from automotive to aerospace, electronics to medical devices, and even luxury goods. These precision tools have significantly boosted efficiency, with automotive body assembly 35% faster, aerospace joints 50% stronger, and electronics battery sealing achieving a 99.9% leak-proof rate. The key to maximizing LWM potential lies in careful selection and maintenance, considering factors such as welding requirements, power systems, support, cost-effectiveness, material compatibility, automation features, and safety compliance.

As laser technology continues to evolve, manufacturers who invest wisely in LWMs and stay current with advancements will be well-positioned to meet future quality demands while optimizing production. LWMs are not just tools, but strategic assets in the pursuit of manufacturing excellence, shaping the future of precision manufacturing with their unparalleled capabilities. Their impact on production processes underscores their potential to drive innovation and quality improvements across the manufacturing landscape.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Compare picosecond vs nanosecond laser systems for industrial manufacturing. HAZ data, processing speeds, cost analysis, and application criteria from OPMT’s deployed systems.

PCD laser cutting machines deliver 0.003mm accuracy and 3x faster processing than EDM. Complete technical guide to polycrystalline diamond tool manufacturing for aerospace and automotive industries.

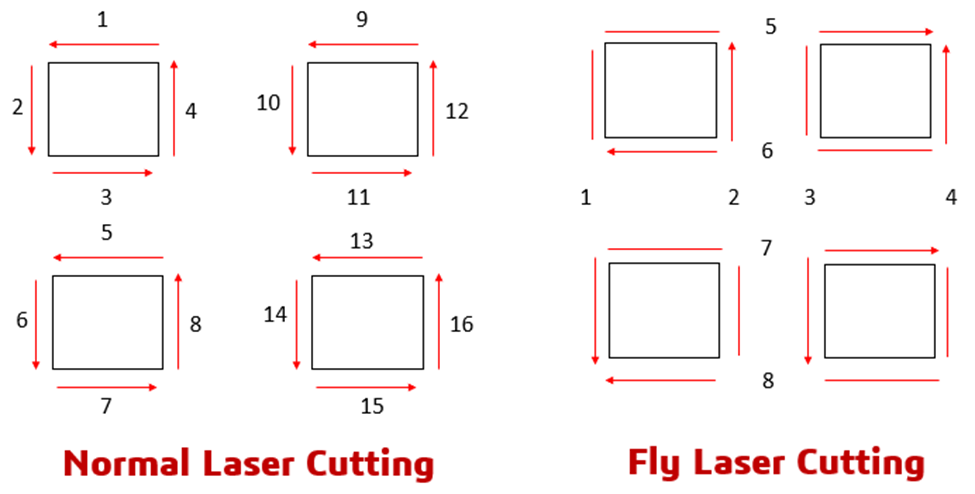

Fly cut laser technology reduces cycle time by 30-50% through continuous motion path optimization. Learn mechanics, applications, and OPMT equipment specifications for precision manufacturing.

Factory evaluation frameworks for laser cutting equipment procurement. Infrastructure assessment, quality systems analysis, and total cost of ownership calculations based on 30+ facility audits.

Please fill in your contact information to download the PDF.