Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Are you exploring the possibilities of laser processing but unsure which materials are compatible? You’re not alone—many industries face this challenge. At OPMT Laser, we understand the importance of precision and versatility in laser applications. Whether you’re working with metals, plastics, ceramics, or even fabrics, our advanced laser solutions, like the Micro3DL530V or LP550V, are designed to deliver exceptional results.

This guide has covered the key materials suitable for laser processing, from cutting and engraving to welding and marking. With over 90% of manufacturers relying on laser technology for precision tasks, the right equipment makes all the difference. Ready to elevate your projects? Discover how OPMT Laser can transform your workflow—explore our laser applications guide today!

Laser processing has become an essential technique in modern manufacturing, allowing for the precise manipulation of various metals. Understanding the compatibility of different metals with laser technology is crucial for achieving optimal results in cutting, welding, and marking. This guide explores the most commonly processed metals, detailing their properties and suitability for laser applications.

Steel is a highly versatile material in laser processing, encompassing carbon steel, stainless steel, and tool steel.

For advanced solutions in CNC systems and laser processing, consider exploring OPMT Laser’s LP550V model.

Aluminum is a lightweight metal that is widely used in laser processing due to its favorable strength-to-weight ratio.

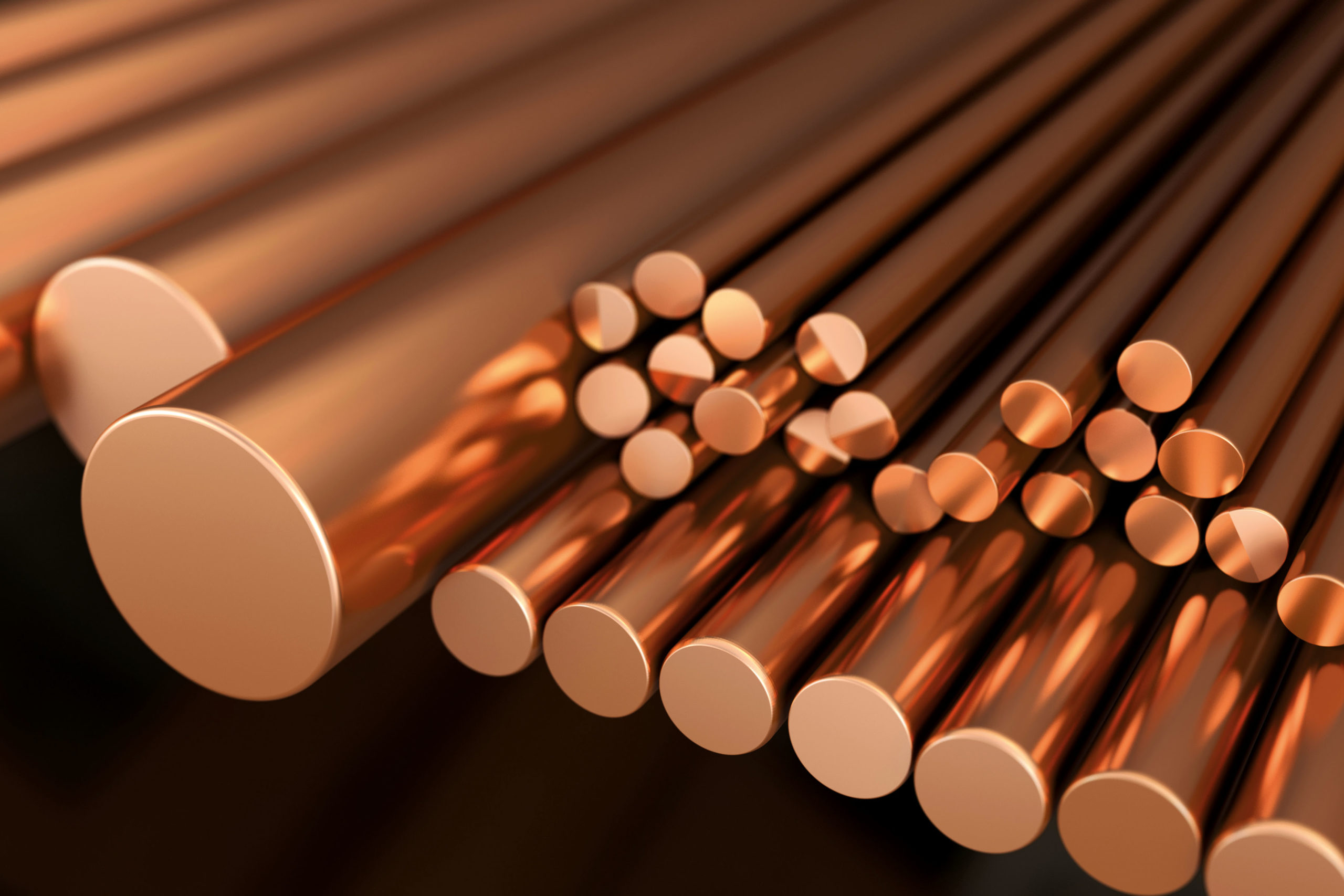

Copper presents unique challenges in laser processing due to its high thermal conductivity and reflectivity.

Titanium is celebrated for its exceptional strength-to-weight ratio and corrosion resistance.

For innovative CNC systems tailored to meet your needs, check out OPMT Laser’s Micro3D-L570V.

Brass and bronze are alloys that also benefit from laser processing.

Understanding the compatibility of various plastics with laser processing is essential for achieving optimal results in manufacturing. Different types of plastics exhibit unique properties that influence their behavior during laser cutting and engraving. This guide explores the most commonly used plastics in laser applications, highlighting their characteristics and best practices for effective processing.

Acrylic, or PMMA, is a top choice for laser cutting and engraving due to its versatility. It allows for smooth, polished edges, making it ideal for applications where aesthetics matter.

For those interested in advanced laser systems, OPMT Laser offers a range of solutions tailored for acrylic processing, such as the Micro3D-L530V.

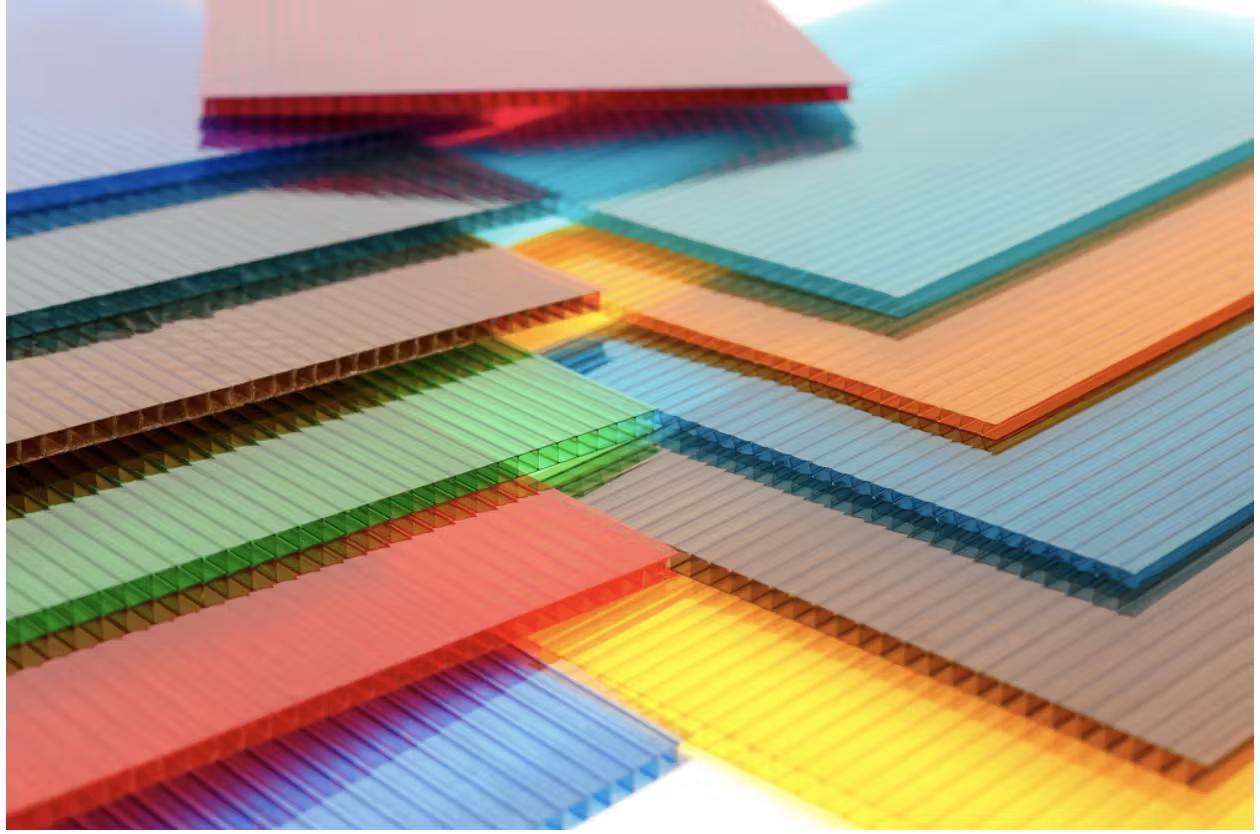

Polycarbonate is another widely used plastic in laser processing. While it can be effectively cut and marked, it requires careful handling due to its sensitivity to heat.

For reliable results with polycarbonate, consider OPMT Laser’s LP550V model, which is designed for precision cutting.

Polyethylene is suitable for both marking and cutting but demands precise control during processing.

Explore OPMT Laser’s offerings like the Lightmut 750V for effective PE processing solutions.

Similar to polyethylene, polypropylene requires careful handling to achieve clean cuts.

OPMT Laser’s Diacut-L315V is an excellent option for those looking to work with polypropylene effectively.

ABS is commonly used in prototyping and offers good compatibility with laser technologies.

For high-quality ABS processing, OPMT Laser’s Lightgrind LT20 can deliver precision results.

Composite materials and ceramics are at the forefront of modern manufacturing, offering unique challenges and opportunities for laser processing. Understanding these materials is essential for optimizing their applications in various industries.

Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a popular choice in many high-performance applications. When it comes to laser processing, this material can be precisely cut and marked. However, it’s crucial to manage heat effectively to prevent delamination, which can compromise the material’s integrity. Have you considered how the right laser settings can enhance your carbon fiber projects? OPMT Laser’s innovative CNC systems provide tailored solutions that ensure optimal results while minimizing risks associated with thermal damage.

Fiberglass is another versatile composite that lends itself well to laser cutting and marking. While it offers great flexibility in design, it also produces hazardous fumes during processing. This necessitates stringent safety measures to protect operators. Are you aware of the best practices for working with fiberglass? Utilizing advanced laser technology from OPMT Laser can help mitigate these risks while delivering high-quality finishes.

Alumina, a widely used ceramic material, excels in marking and engraving applications due to its hardness. However, its robust nature poses challenges when cutting. To achieve clean cuts without damaging the material, precise control over laser parameters is essential. How can you leverage laser technology to enhance your alumina processing? OPMT Laser’s systems are designed to optimize cutting efficiency while maintaining the integrity of your products.

Zirconia is frequently employed in medical and dental applications due to its durability and precision. Laser processing allows for the creation of intricate shapes that meet stringent quality standards. Are you looking for ways to improve your zirconia applications? With OPMT Laser’s advanced solutions, you can achieve unparalleled precision and efficiency in your manufacturing processes.

Laser processing has transformed the way intricate designs are crafted on materials such as glass and stone. This technology allows for high precision in cutting, engraving, and marking, enabling both artistic expression and functional applications. However, the unique properties of these materials can pose challenges during processing. How can one effectively overcome these obstacles while achieving stunning results?

When it comes to laser processing, two primary types of glass are commonly used: borosilicate glass and soda-lime glass.

For stone materials like granite and marble, laser engraving offers unique advantages.

Cutting through glass and stone can be challenging due to their inherent characteristics. To address these difficulties, several methods are employed:

Understanding these techniques is essential for achieving optimal results in laser processing.

At OPMT Laser, we utilize cutting-edge laser technology to enhance our work on glass and stone. Our advanced systems enable us to achieve high precision while minimizing waste. Here’s how we ensure top-quality results:

Laser processing has become a game-changer in the treatment of various natural and synthetic materials, particularly wood and textiles. This innovative technology is widely utilized in both creative and industrial applications due to its precision and efficiency. By employing advanced CNC systems, OPMT Laser offers solutions that enhance the capabilities of businesses looking to leverage these materials.

Laser processing is a game-changer for materials like paper, cardboard, and rubber, delivering unmatched precision and versatility. This technology not only enhances manufacturing efficiency but also opens up creative possibilities across various industries.

When it comes to paper, laser cutting and engraving stand out as the preferred methods. This technique is particularly effective for intricate designs often used in packaging and artistic projects.

For more on our laser solutions tailored for paper processing, explore our Micro3D L530V model.

Cardboard is another material that benefits significantly from laser technology. Its lightweight yet durable nature makes it ideal for various applications in packaging and prototyping.

To see how our systems can enhance your cardboard processing capabilities, check out the LP550V.

Both natural and synthetic rubber are effectively processed using laser technology.

For insights into our advanced laser solutions designed for rubber processing, visit our LightMut 750V page.

When it comes to laser processing, understanding the unique requirements of different materials is crucial for ensuring safety and achieving high-quality results. OPMT Laser specializes in innovative CNC systems and laser processing solutions, making it essential to consider specific factors that may affect the laser cutting and engraving process.

Certain metals, such as copper and gold, are highly reflective and can pose challenges during laser processing. These materials often require specialized equipment to achieve optimal results.

Processing materials like PVC can release toxic fumes, which necessitates careful handling to ensure operator safety.

To maintain a safe environment during laser processing, consider these best practices:

By focusing on these special considerations when processing reflective materials and managing hazardous fumes, OPMT Laser can enhance both safety and efficiency in its operations. For those looking to explore advanced laser solutions, consider our Micro3D L530V or LP550V models that are designed for precision and reliability in various applications.

At OPMT Laser, we specialize in innovative CNC systems and laser processing solutions tailored to meet your specific material and application requirements. Our cutting-edge technology ensures precise, efficient, and safe processing across a diverse range of materials, including metals, plastics, ceramics, and fabrics. But what truly sets OPMT Laser apart in the competitive landscape of laser processing?

Our laser systems are engineered to handle a wide variety of materials effectively. Whether you need to cut robust metals or engrave intricate designs on delicate fabrics, our technology adapts seamlessly to your needs. This versatility not only enhances productivity but also allows for creative freedom in design. With OPMT Laser, you can confidently tackle any project, knowing our systems are equipped for optimal performance.

When it comes to laser processing, precision is paramount. OPMT Laser’s advanced technology guarantees high-speed operations without sacrificing quality. Our systems minimize waste and maximize output, making them an economical choice for businesses aiming to enhance their manufacturing processes. Why settle for less when you can achieve exceptional results with our state-of-the-art solutions?

Safety is a critical consideration in any manufacturing environment. At OPMT Laser, we prioritize operator safety by incorporating advanced safety features into our systems. Protective enclosures and automated shutdown protocols are just a few examples of how we ensure a secure working environment while maintaining high productivity levels. Your safety is our commitment.

Our laser processing solutions are not limited to one industry; they span multiple sectors including automotive, textiles, and electronics. The adaptability of our technology allows it to be used for cutting, engraving, welding, and marking applications. This multi-functionality means that no matter your industry or specific needs, OPMT Laser has the right solution for you.

Staying ahead of the curve is crucial in today’s fast-paced market. OPMT Laser continually invests in research and development to bring you the latest advancements in laser technology. Our commitment to innovation ensures that you benefit from cutting-edge performance that meets and exceeds industry standards.

Choosing OPMT Laser means gaining access to unparalleled customer support throughout your project lifecycle. Our team of experts is dedicated to understanding your unique needs and providing tailored solutions that drive success. From initial consultations to ongoing maintenance, we are committed to ensuring your experience with our products is seamless.

What materials can be processed with OPMT Laser systems?

Our systems are designed to process a variety of materials including metals, plastics, ceramics, and fabrics, ensuring versatility for all your projects.

How does laser processing improve efficiency?

Laser processing combines cutting and finishing steps into one operation, significantly reducing waste and speeding up production times compared to traditional methods.

What safety measures are implemented in OPMT Laser systems?

We incorporate multiple safety features such as protective enclosures and automated shutdown protocols to ensure a safe working environment during operations.

Can OPMT Laser technology be integrated into existing production lines?

Absolutely! Our solutions can be customized to integrate seamlessly into your current production processes without major disruptions.

Laser processing is an incredibly versatile technology that can work wonders with a wide range of materials, from metals and plastics to wood and glass. By selecting the appropriate laser type and adjusting processing parameters, you can achieve outstanding results tailored to your specific needs. Did you know that laser cutting can be up to 10 times faster than traditional methods? This efficiency can significantly enhance your production capabilities.

At OPMT Laser, we understand your desire for precision and safety in your projects. That’s why we offer a variety of laser solutions designed to meet diverse material requirements while prioritizing safe practices. Explore our innovative products like the LP550V or the LightMut 750V to find the perfect fit for your applications. Ready to elevate your laser processing experience? Contact OPMT Laser today and discover how we can help you achieve remarkable results!

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.