Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Understanding material selection for laser processing applications requires comprehensive analysis of thermal, optical, and mechanical properties that directly influence processing outcomes and component quality. This technical analysis examines the fundamental differences between Nylon 12 (PA12) and Polypropylene (PP) for industrial laser manufacturing, providing engineers with evidence-based insights for optimal material selection and process optimization strategies.

The selection between PA12 and PP involves critical considerations including thermal characteristics, moisture absorption properties, and laser processing compatibility. These materials serve different roles across automotive, electronics, and medical device manufacturing sectors, each offering distinct advantages depending on specific application requirements and processing conditions.

Based on established material property databases and industry standards, PA12 and PP demonstrate significantly different thermal behaviors that directly impact laser processing parameters and quality outcomes.

Nylon 12 (PA12) Thermal Profile:

Polypropylene (PP) Thermal Profile:

The fundamental difference in moisture absorption represents a critical factor for laser processing applications. PA12’s higher moisture absorption can impact dimensional stability in humid environments, while PP maintains consistent properties across varying environmental conditions.

According to OPMT’s materials compatibility guide, both PA12 and PP are suitable for laser processing applications, though each material requires specific parameter optimization for optimal results.

Polypropylene (PP) Processing Characteristics:

Nylon 12 (PA12) Processing Advantages:

OPMT’s processing guidelines emphasize the importance of material-specific parameter optimization. For PP applications, precision laser cutting technology requires careful power density control and thermal management to prevent material distortion.

The automotive sector utilizes both materials for different applications based on their specific properties and processing characteristics.

PA12 Automotive Applications:

PP Automotive Applications:

3C electronic digital industry solutions benefit from both materials depending on specific requirements. The electronics sector particularly values PA12 for applications requiring dimensional stability and mechanical strength, while PP serves applications where moisture resistance and cost effectiveness are prioritized.

Key Electronics Applications:

OPMT’s advanced laser processing systems are specifically designed to handle diverse materials including PA12 and PP. The Light 5X Series laser machining centers provide the precision and control necessary for optimal processing of both materials.

Light 5X 40V Technical Specifications:

Light 5X 60V Enhanced Capabilities:

Laser texturing and surface modification technologies demonstrate particular advantages with both PA12 and PP materials. OPMT’s Micro3D L570V system enables complex surface patterns and microstructures that enhance functionality while maintaining processing efficiency.

L570V Texturing Capabilities:

Based on OPMT’s engineering team evaluation criteria, material selection involves three critical factors: environmental conditions, mechanical demands, and budget constraints.

Choose PA12 when:

Choose PP when:

Successful implementation requires careful consideration of processing parameters specific to each material. OPMT’s experience demonstrates that material-specific optimization delivers superior results compared to generic processing approaches.

PA12 Optimization Approach:

PP Optimization Approach:

Both materials can achieve compliance with relevant industry standards when processed with appropriate parameters. OPMT’s laser processing systems maintain comprehensive certification compliance including CE marking, ISO 14001 environmental standards, and RoHS compliance for electronic applications.

OPMT’s manufacturing processes and equipment meet stringent quality standards:

Phase 1: Material Assessment

Phase 2: Parameter Optimization

Phase 3: Production Implementation

OPMT’s commitment to technological advancement continues to enhance processing capabilities for both PA12 and PP materials. The integration of advanced monitoring systems and adaptive control technologies enables real-time optimization for consistent quality outcomes.

Innovation Focus Areas:

The selection between PA12 and PP for laser processing applications depends on specific requirements including mechanical properties, environmental conditions, and economic considerations. PA12 offers superior mechanical performance and chemical resistance, making it ideal for demanding applications in automotive and aerospace sectors. PP provides excellent moisture resistance and cost effectiveness, suitable for applications where these characteristics are prioritized.

OPMT’s advanced laser processing systems deliver optimized results for both materials through precise parameter control and comprehensive process monitoring. The combination of technical expertise, advanced equipment, and comprehensive support ensures successful implementation regardless of material selection.

For optimal PA12 and PP laser processing capabilities, OPMT offers comprehensive solutions:

Contact OPMT Laser’s technical specialists to explore how advanced laser processing technology can optimize your manufacturing operations with the most suitable material selection for your specific application requirements.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

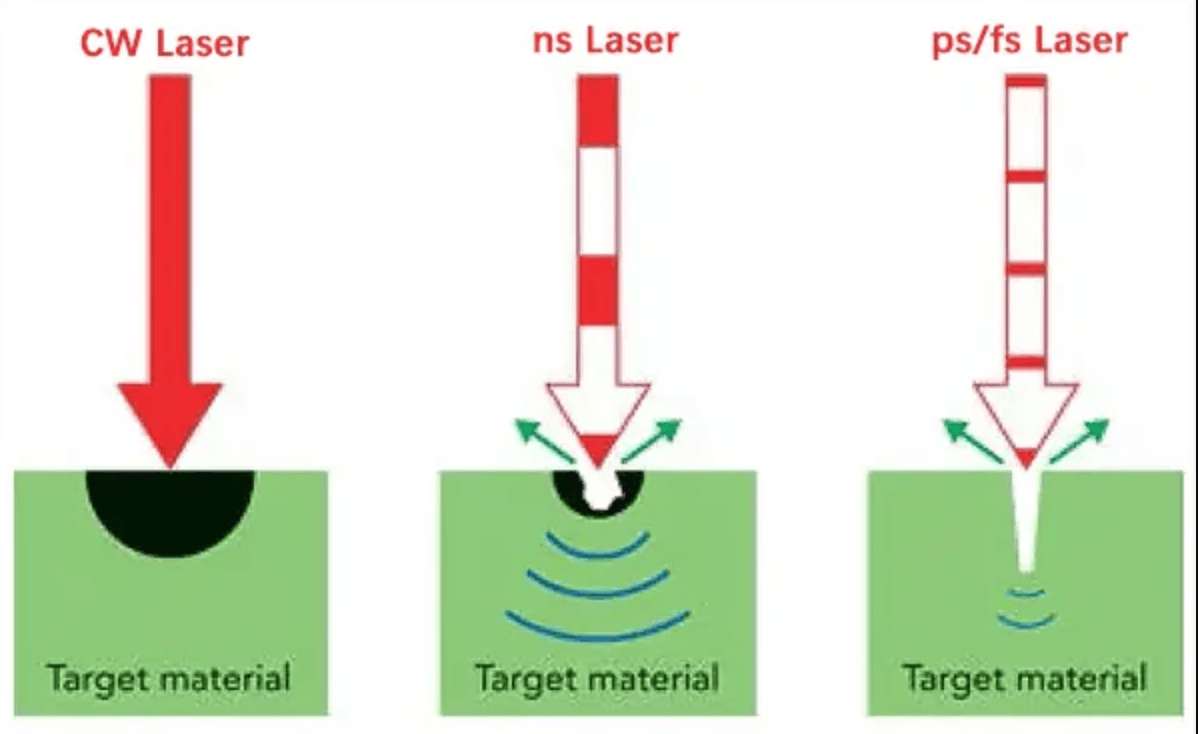

Compare picosecond vs nanosecond laser systems for industrial manufacturing. HAZ data, processing speeds, cost analysis, and application criteria from OPMT’s deployed systems.

PCD laser cutting machines deliver 0.003mm accuracy and 3x faster processing than EDM. Complete technical guide to polycrystalline diamond tool manufacturing for aerospace and automotive industries.

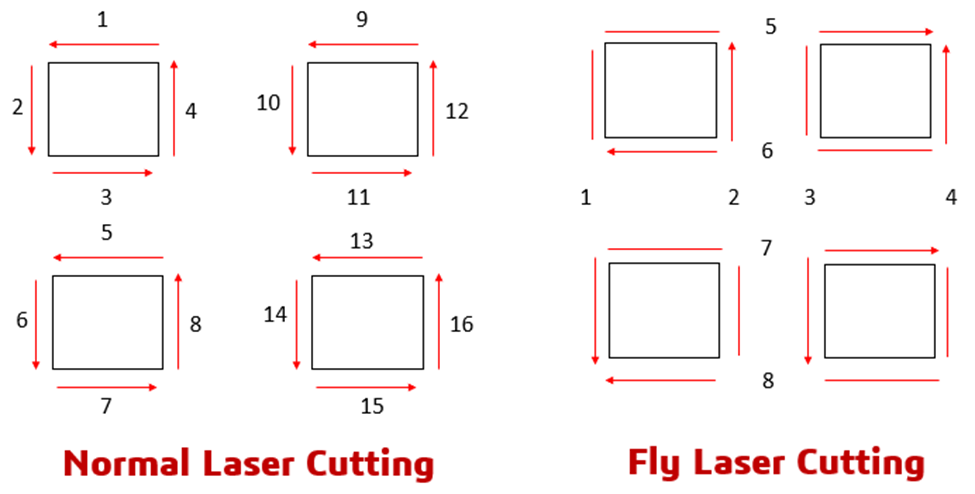

Fly cut laser technology reduces cycle time by 30-50% through continuous motion path optimization. Learn mechanics, applications, and OPMT equipment specifications for precision manufacturing.

Factory evaluation frameworks for laser cutting equipment procurement. Infrastructure assessment, quality systems analysis, and total cost of ownership calculations based on 30+ facility audits.

Please fill in your contact information to download the PDF.