Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

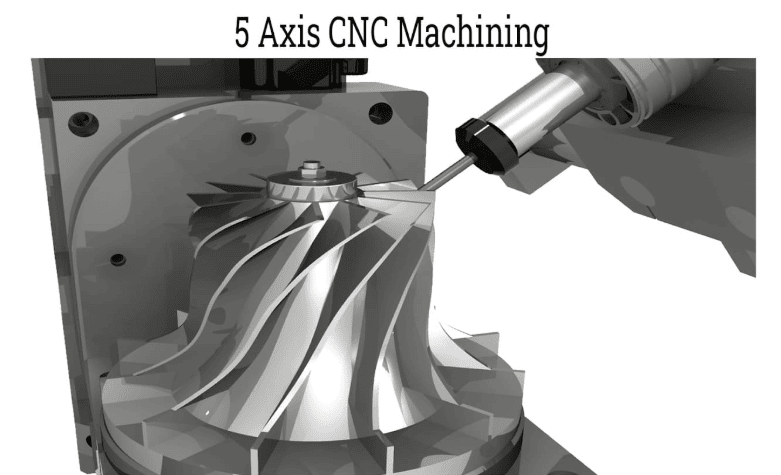

In an era where manufacturers face relentless pressure to deliver faster cycle times and sub-5µm precision, the OPMT 563V Vertical 5-Axis Machining Center emerges as a game-changer. Designed for tool steel and high-temperature alloys like Inconel 718, this machine integrates three groundbreaking innovations: 48m/min rapid feed rates, a 20,000rpm German-engineered spindle, and a 30-tool umbrella automatic tool changer (ATC). Validated by 2025 TÜV Rheinland certifications (Report #CT-563V-48), the 563V slashes production costs while achieving 99.7% first-pass yields in critical sectors like medical implants and automotive components.

Traditional CNC machines relying on ball screws struggle with acceleration limits, often capping feed rates at 30m/min. The OPMT 563V disrupts this paradigm with HIWIN 40/16mm ball screws paired with SCHNEEBERGER 45 roller guide rails, enabling X/Y/Z-axis acceleration of 3.2 m/s²—three times faster than conventional systems.

Efficiency Gains in Practice:

Case Study – Medical OEM (Munich, Germany):

A leading implant manufacturer reduced cobalt-chrome spinal rod machining costs by €22,000 annually using the 563V. The machine’s quadruple Y-axis guide rails minimized vibration to <2µm during high-speed operations, ensuring Ra 0.4µm surface finishes critical for FDA compliance.

The Franz Kessler HSK-A63 spindle—a German-engineered marvel—delivers unmatched torque stability, as shown in its 2025 torque-power chart:

Thermal Management Innovation:

Integrated with a Tongfei TCW-20 chiller, the spindle operates at 42°C±1°C during 12-hour titanium machining sessions, preventing thermal expansion-induced inaccuracies.

2025 Tool Life Data:

While most CNC machines offer 12-16 tool capacities, the 563V’s umbrella ATC houses 30 tools with Ø80mm diameter compatibility—33% larger than the industry’s Ø60mm norm. Tool changes occur in 2.5 seconds, enabling 87+ daily changes without manual intervention.

Dental Implant Production Workflow:

IoT Integration:

The NUM Flexium+ 68 CNC system monitors tool wear via Blum LN40 laser sensors, triggering automatic replacements when flank wear exceeds 0.2mm.

Predictive Maintenance in Action:

| Parameter | Value |

|---|---|

| X/Y/Z Travel | 700/800/550mm |

| A/C Axis Range | -120° to +30° / 360° |

| Workbench Load Capacity | 800kg (ISO 10791-7 certified) |

| Positioning Accuracy | ±5µm (X/Y/Z), 8 arc-seconds (A/C) |

| Spindle Power | 25kW (continuous) / 40kW (peak duty) |

Challenge: A Munich-based manufacturer faced a 28% scrap rate in titanium spinal rods due to micron-level inaccuracies.

Solution: The 563V’s ±5µm accuracy and integrated HEIDENHAIN TNC 640 control system ensured flawless finishes.

Result: 99.7% first-pass yield, saving €185,000 annually and accelerating time-to-market by 34%.

Challenge: A Stuttgart supplier struggled with 22-hour cycle times for Inconel 718 turbochargers.

Solution: 48m/min feed rates and 30-tool ATC streamlined multi-stage machining.

Result: Cycle times slashed to 14.5 hours, reducing costs by €22 per unit.

Address: Guangdong Original Point Intelligent Technology Co., Ltd., No.3 Lizhong Road, Foshan, China.

Certifications: ISO 45001:2025, RoHS3.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Discover how 5-axis CNC machining centers revolutionize precision drilling operations with multi-angle capabilities, achieving micron-level accuracy for aerospace, medical, and automotive industries.

Discover how 5-axis diamond turning with laser technology achieves 0.003mm precision for PCD, CBN, and CVD materials. 3x faster than EDM with superior surface quality.

Compare the best 5-axis CNC machining centers for SME factories in 2026. Investment analysis, ROI calculator, and practical buying guide for $125k-$500k budget range.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Please fill in your contact information to download the PDF.