Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

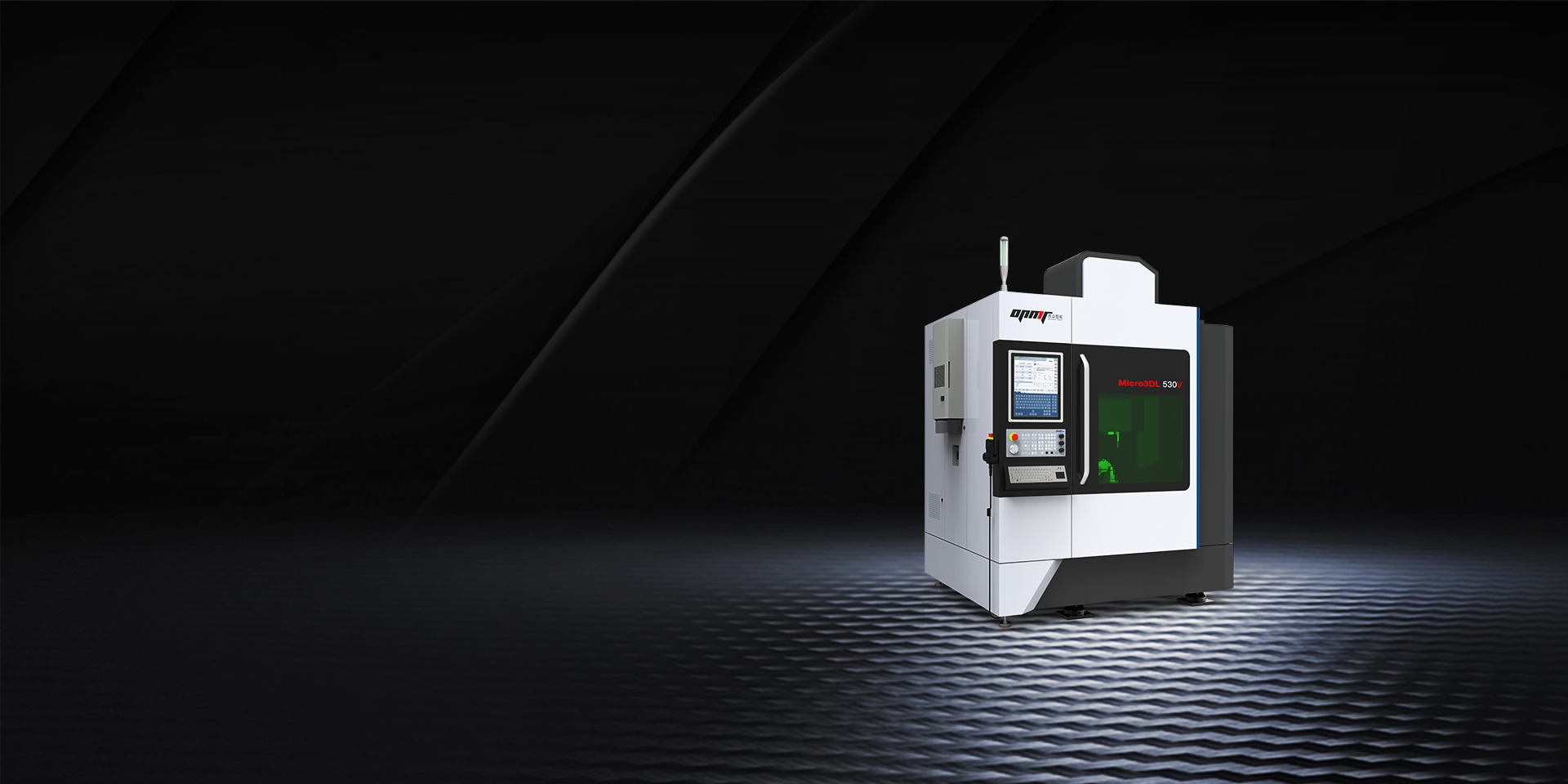

OPMT Laser’s ISO 9001-certified femtosecond CNC platforms deliver sub-300 fs pulse widths, M² ≤ 1.2 beam quality, and < 0.5% RMS pulse stability to achieve sub-0.1 µm surface finishes and ± 0.003 mm positioning accuracy. Complying with IEC 60825-1 Class 4 safety and FDA 21 CFR §820 quality regulations, these systems sustain MTBF > 20,000 hours through HALT/HASS validation and provide 24/7 reliability. This article offers an in-depth technical exploration of core specifications, optical and software architectures, real-world applications, commissioning procedures, comparative analyses, and case studies to showcase OPMT Laser’s industry leadership.

The following table summarizes the key performance metrics for OPMT Laser’s flagship Micro3D L530V and Light 5X 60V platforms, illustrating their ultrafast-pulse machining capabilities.

| Specification | Micro3D L530V Five-Axis | Light 5X 60V Vertical Five-Axis |

|---|---|---|

| Laser Source | All-fiber IR femtosecond, ≤ 400 fs, ≥ 1 MHz rep. rate | IR femtosecond, 40 W average power |

| Travel Range | X/Y/Z: 300 × 300 × 260 mm; B: ± 120 °; C: 360 ° | X/Y/Z: 600 × 250 × 300 mm; Workbench: 500 × 500 mm |

| Positioning Accuracy | X/Y/Z: ± 0.003 mm; B/C: 5″ | X/Y/Z: ± 0.005 mm; B/C: 10″ |

| Repeatability | X/Y/Z: ± 0.002 mm; B/C: 3″ | X/Y/Z: ± 0.003 mm; B/C: 5″ |

| Material Removal Precision | < 1 µm | One-clamp rough/finish of complex contours |

| Optics | Telecentric fused-quartz F-theta lens | High-mag CCD camera; infrared measuring probe |

| Drive System | Linear motors (X/Y/Z); torque motors (B/C) | Linear motors (X/Y/Z); torque motors (B/C) |

| Machine Footprint (L×W×H) | 2,680 × 2,020 × 2,600 mm; 6,000 kg | 2,300 × 2,400 × 2,600 mm; 4,500 kg |

| Compliance | IEC 60825-1, ISO 9001 | IEC 60825-1, ISO 9001 |

These platforms’ modular architecture supports optional UV and green lasers, burst-mode operation, and process-optimized galvanometer configurations to tailor machining for ceramics, CBN, PCD, and diamond materials.

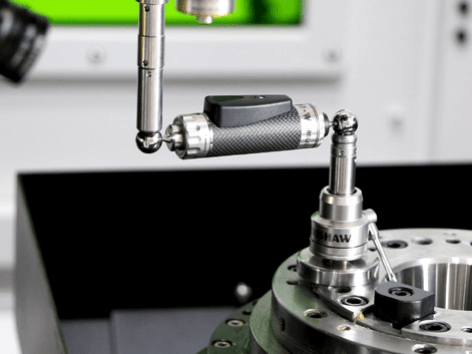

OPMT Laser’s optical path leverages a fused-quartz telecentric F-theta lens to maintain a uniform spot profile across the field, minimizing spherical aberration and ensuring ≤ 5 µm focal-plane deviation. The closed-loop 3D galvanometer uses high-speed scanners with < 1 ms settling times for precise beam steering. Mechanically, linear-motor drives on X/Y/Z axes provide nanometer-scale positioning, while torque-motor B/C axes enable high-torque rotation with minimal backlash. The granite-based machine bed dampens vibration, and integrated air-knife systems remove debris to protect optics.

OPMT Laser’s proprietary GTR CNC software integrates CAD/CAM programming, parameter libraries, and real-time process monitoring. Key modules include:

Software updates and parameter backups are delivered securely via OPMT’s cloud portal to ensure continuous performance improvements.

Successful deployment requires structured commissioning and routine care:

A 3C electronics manufacturer adopted the Micro3D L530V to texture tungsten-carbide chip-breaker grooves. Within 20 days, cycle times fell by 65%, surface roughness improved from Ra 0.4 µm to Ra 0.05 µm, and first-pass yield rose from 82% to 97%, delivering a 28% OEE uplift.

An automotive tooling supplier implemented the Light 5X 60V vertical five-axis system. Thanks to integrated high-mag CCD imaging and infrared probing, rough and finish passes completed in one clamping, reducing cycle time by 70% and cutting costs by 50% compared to EDM.

In a photonics R&D lab, the Micro3D L530V generated sub-200 nm periodic nanostructures on fused silica for anti-reflective and hydrophobic surfaces. The system’s telecentric lens and burst-mode control produced uniform LIPSS patterns at 100 mm²/min.

| Criterion | Femtosecond CNC | Nanosecond Laser | EDM |

|---|---|---|---|

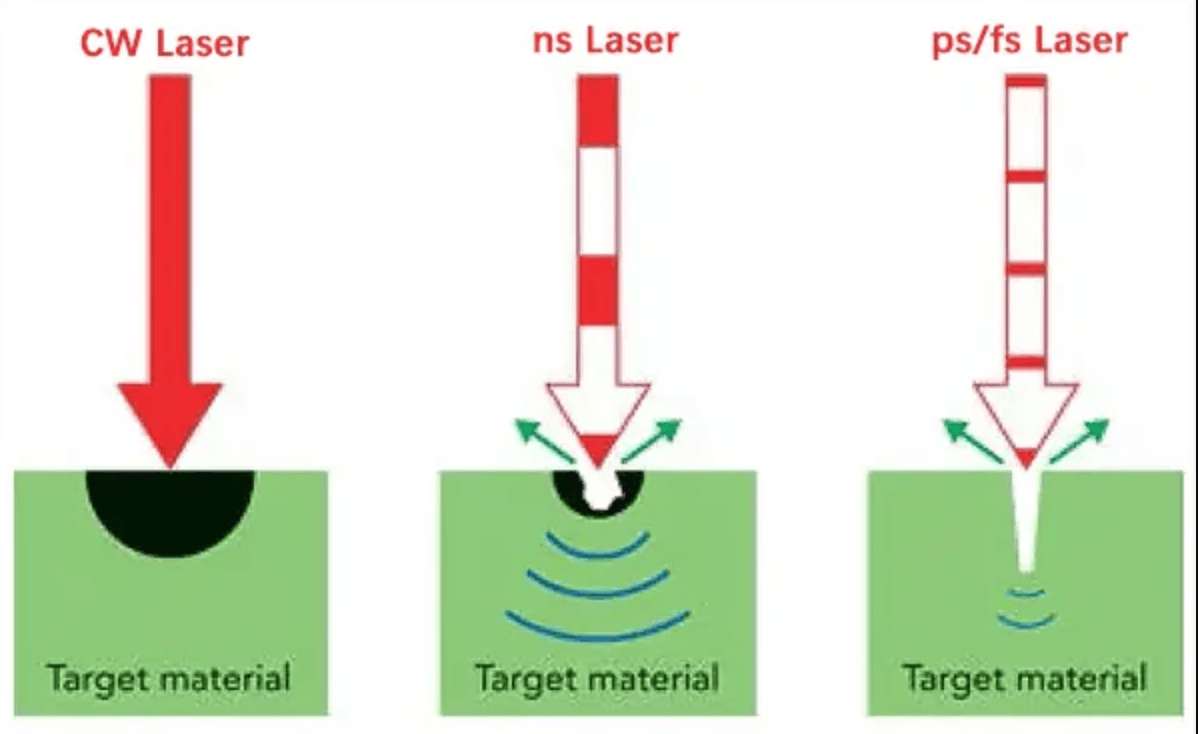

| Heat-Affected Zone (HAZ) | < 1 µm | 10–50 µm | None (recast layer) |

| Surface Roughness (Ra) | < 0.1 µm | 0.3–1.5 µm | 0.2–0.8 µm |

| Material Scope | Metals, ceramics, polymers | Limited ceramics | Conductive materials only |

| Throughput | 15–50 mm³/min | 5–20 mm³/min | 1–5 mm³/min |

| Precision Tolerance | ± 0.003 mm | ± 0.010 mm | ± 0.005 mm |

| Tool Wear | None (non-contact) | None | High (electrode wear) |

This comparison highlights femtosecond-pulse machining’s superior precision, minimal thermal load, and broad material compatibility.

OPMT Laser’s femtosecond CNC systems are engineered to meet the most stringent global regulations, ensuring seamless adoption in safety-critical industries. Each platform incorporates IEC 60825-1 Class 4 interlock circuits and key-switch controls that prevent accidental exposure to ultrafast pulses. Quality management adheres to ISO 9001 and environmental stewardship follows ISO 14001, providing customers with documented processes for consistent product excellence and sustainability. For medical-device applications, the systems comply with FDA 21 CFR §820 QSR requirements, supported by traceable validation protocols and detailed Device Master Records. Additionally, RoHS and CE certifications guarantee material conformity and export readiness, expediting regulatory reviews and accelerating time to market.

Beyond hardware, OPMT Laser delivers a software ecosystem designed for Industry 4.0 connectivity and data-driven performance optimization. Native OPC UA support enables bi-directional communication between the CNC controller and enterprise MES/ERP systems, allowing real-time updates to job orders, process parameters, and maintenance schedules. An embedded AI analytics module continuously monitors vibration signatures, thermal profiles, and beam stability, generating predictive maintenance alerts before critical components reach end-of-life. This proactive approach reduces unplanned downtime by up to 40% and maintains first-pass yields above 95%. Secure cloud-based firmware updates and parameter backups ensure each machine benefits from the latest feature enhancements without disrupting production.

OPMT Laser’s femtosecond CNC solutions unify ultrafast-pulse performance with robust compliance frameworks and intelligent factory integration. By aligning IEC 60825-1, ISO 9001/14001, and FDA 21 CFR §820 standards with OPC UA communication and AI-driven analytics, these platforms deliver sub-micron precision, industry-proven reliability, and measurable productivity gains. Manufacturers in medical, electronics, automotive, and aerospace sectors can confidently adopt OPMT Laser technology to shorten validation cycles, optimize throughput, and maintain stringent quality controls—turning complex micromachining challenges into competitive advantages.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Compare picosecond vs nanosecond laser systems for industrial manufacturing. HAZ data, processing speeds, cost analysis, and application criteria from OPMT’s deployed systems.

PCD laser cutting machines deliver 0.003mm accuracy and 3x faster processing than EDM. Complete technical guide to polycrystalline diamond tool manufacturing for aerospace and automotive industries.

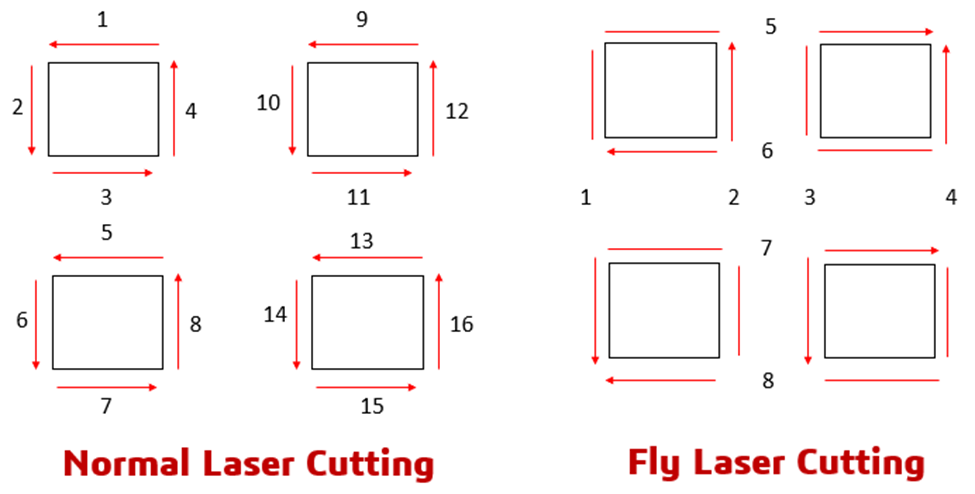

Fly cut laser technology reduces cycle time by 30-50% through continuous motion path optimization. Learn mechanics, applications, and OPMT equipment specifications for precision manufacturing.

Factory evaluation frameworks for laser cutting equipment procurement. Infrastructure assessment, quality systems analysis, and total cost of ownership calculations based on 30+ facility audits.

Please fill in your contact information to download the PDF.