Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Guangdong Origin Intelligence Technology Co., Ltd., founded in 2015, is a company dedicated to the development, production, and manufacturing of multi-axis CNC systems—often referred to as the “brain” of industrial mother machines—with a focus on five-axis and higher-axis linkage systems. By integrating CNC systems with industrial software, the company offers intelligent manufacturing solutions centered around laser CNC machine tools.

Through continuous technological innovation and product breakthroughs, Origin Intelligence has rapidly risen to become one of the few innovative enterprises in China that possesses dual R&D capabilities in high-end five-axis and above CNC systems and multi-axis ultra-precision laser machine tools. The company has been honored with titles such as National “Little Giant” Enterprise in Specialized, Refined, Distinctive, and Innovative Development, and National Intellectual Property Advantage Enterprise. According to Laser Manufacture News, Origin Intelligence’s development over the past decade can be divided into two strategic five-year phases:

The First Five-Year Plan (2015–2019): This was a period of technical breakthroughs and product stabilization. During this phase, the company successfully achieved core technological advancements in both CNC systems and mechanical machine tools, forming its two main business lines: high-end CNC laser machine tools and high-end CNC systems.

The Second Five-Year Plan (2020–2024): Building upon its earlier foundation, Origin Intelligence entered a phase of continuous innovation, tackling a series of technical challenges ranging from CAM software to advanced optical systems. During this period, products began to be produced in volume and were highly recognized by customers. The company’s flagship five-axis laser machining centers are now widely applied in fields such as ultra-hard materials, lab-grown diamonds, mold texturing, 3C electronics, and semiconductors.

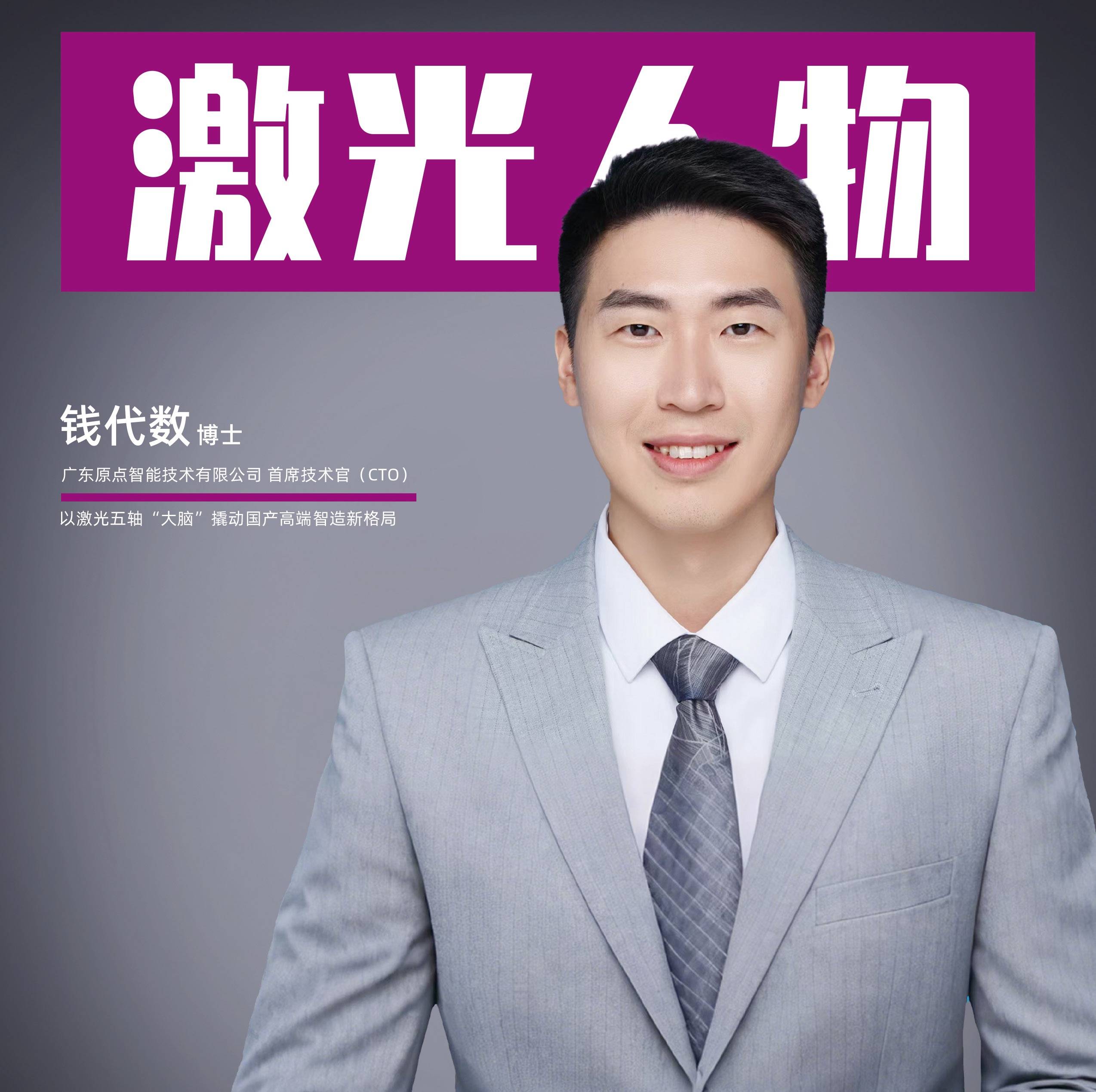

In this issue’s Cover Figure feature, Laser Manufacture News interviewed Dr. Derek Qian, the Chief Technology Officer (CTO) of Origin Intelligence. He provided in-depth insights into the company’s development path from perspectives including technical R&D, market competitiveness, core products, marketing strategies, customer service, and future planning—offering readers a glimpse into the company’s upcoming third five-year plan.

Derek Qian:

In recent years, Origin Intelligence has recruited more than 20 high-level professionals, including PhDs from leading domestic and international universities and senior engineers. This has allowed us to build a highly qualified and skilled team, laying a solid foundation for sustained technological innovation and long-term development. Moreover, we have been actively promoting deep integration of industry, academia, and research to enhance our innovation capabilities. In the field of precision and ultra-precision CNC machine tools, many common industry challenges—such as the complexity of manufacturing processes, and the long cycles required to validate stability and reliability—cannot be easily overcome by a single enterprise alone in a short time frame. To address this, we have established long-term collaborative partnerships with renowned institutions such as the Ningbo Institute of Materials Technology & Engineering, Central South University, and Guangdong University of Technology. By building a think tank of industry experts and forming joint innovation teams with external partners, we conduct collaborative research and tackle key technical problems together. This approach has significantly improved our R&D efficiency and accelerated the pace of technological breakthroughs.

Derek Qian:

In terms of technological direction, Origin Intelligence is one of the few innovative enterprises in China with dual R&D capabilities in multi-axis precision laser CNC machine tools and high-end CNC systems. Our independently developed core technologies in high-end CNC systems have effectively addressed key gaps in the domestic industry. Through repeated R&D efforts, we have independently developed core technologies such as optical system control and laser processing CAM software for laser CNC machine tools. These achievements have led to the launch of a series of high-end laser CNC products, reaching internationally advanced standards and breaking the long-standing dependence on imported high-end laser CNC machines. In terms of intellectual property, we have strategically built a comprehensive patent portfolio covering complete machine tools, core components, process applications, and software algorithms. To date, we hold more than 300 intellectual property rights, including invention patents, utility models, design patents, and software copyrights. With a robust and integrated technical system, our precision laser processing applications are both extensive and highly competitive in the market. Our Phase I Smart Factory project was completed and went into production in July 2024. The facility features a temperature- and humidity-controlled environment, which significantly enhances the precision and stability of machine tool assembly and manufacturing. Additionally, the company has obtained ISO 9001 certification and is equipped with over ten million RMB worth of advanced R&D and inspection instruments, including Zoller tool presetters and laser interferometers, ensuring that our testing data aligns with that of our clients.

Derek Qian:

In the second half of 2024, Origin Intelligence launched two new models targeted at the high-precision mold texturing market: • The Micro3D L530V Five-Axis Femtosecond Laser Machining Center for small and medium-sized components

• The Micro3D L570V Five-Axis Precision Laser Machining Center for mold texturing applications The Micro3D L530V, equipped with our independently developed high-end universal CNC system, is capable of ultra-precise machining of complex surface contours. In applications such as carbide insert processing, it offers several technical advantages: non-contact processing, minimal heat-affected zones, high flexibility, environmental friendliness, and the ability to handle complex surface texturing with extreme accuracy. The Micro3D L570V is designed specifically for complex curved-surface texture structures. It integrates a dedicated five-axis laser workstation software suite with intelligent stitching and full digitalization capabilities. This platform optimizes high-quality femtosecond processing and high-efficiency nanosecond machining for large-sized parts. Key features include:

• Periodic structures,

• 3D texturing,

• Laser matte finishing,

• Region-specific surface mapping on 3D geometries,

• Texture mapping,

• Smart collision detection.

These functions significantly enhance the precision and repeatability of high-end mold manufacturing, effectively solving major challenges in the ultra-precision mold industry. Origin Intelligence’s high-precision mold texturing laser CNC machine series is now widely used in a variety of sectors, including:

• Automotive molds

• Medical device components

• Plastic mold processing

• 3C (smartphone) back covers

• Home appliance surface textures

• Semiconductor microstructures

Derek Qian:

To address the thermal challenges often encountered in traditional laser processing, our company has conducted extensive research and technological development in laser-jet hybrid processing technologies. As a result, we have successfully developed the WJL 3X/5X Series Waterjet-Guided Laser Machining Systems. These systems are capable of cutting and drilling flat workpieces as well as complex-shaped components using waterjet-guided laser technology. They are particularly well-suited for applications in aerospace, 3C electronics & semiconductors, microelectronics, medical devices, and other high-precision fields. The WJL systems are designed to process metals, semiconductors, and composite materials that are traditionally difficult to machine.

Derek Qian:

Origin Intelligence focuses on two main business segments: high-end laser CNC machine tools and advanced CNC systems. Through continuous technological innovation and product breakthroughs, we have quickly grown into one of the few innovative enterprises in China with dual R&D capabilities in multi-axis precision laser CNC machines and high-end CNC systems. Notably, 90% of the core components in our high-end laser CNC machines have been localized, making us a trusted supplier in sectors such as aerospace, ultra-hard materials, and lab-grown diamonds. In terms of market expansion, Origin Intelligence is pursuing several key strategies:

1.Positioning of CNC Systems in the Mid-to-High-End Segment

Our self-developed CNC systems are clearly positioned in the mid- to high-end market. Backed by a wealth of technical expertise and patented innovations, our CNC systems have been verified through extensive industrial applications and are now used by several leading enterprises in the industry. This marks a significant breakthrough in overcoming long-standing dependency on foreign high-end CNC technology.

2. High-Quality Laser CNC Machines Enable Import Substitution

The performance gap between Origin’s laser CNC machines and similar models from top international manufacturers has been significantly reduced, enabling effective import substitution. Our machines are designed not only to replace imported laser equipment but also to substitute traditional grinding machines and metal-cutting centers.

For example, in the ultra-hard cutting tools sector, our Light5X 40V (for 3C applications), Light5X 40VP (for ultra-precision machining), and Light5X 60V (for the automotive industry) offer performance metrics comparable to major international brands. Additionally, core components—including the CNC system, laser source, rotary table, and optical control system—are now entirely localized, enabling high-speed, high-precision machining of complex ultra-hard tools, such as PCD micro-edge cutters. Origin also has a significant price advantage. Based on market surveys comparing base model configurations, our five-axis laser machining centers are typically priced at around 60% of similar overseas products, offering exceptional cost-performance value.

3. Integration into the Supply Chains of the Cutting Tool and Aerospace Sectors

Our expansion is closely tied to high-growth downstream industries, which provide a stable foundation for long-term revenue. Customer industries include aerospace, ultra-hard tooling, automotive, mold manufacturing, medical devices, and semiconductors—sectors that are generally resilient to market fluctuations. In particular, the cutting tool, aerospace, and automotive industries are benefiting from increased defense spending, supportive policies, and ongoing technological innovation, all of which ensure a sustained high level of demand. Leveraging our technical strengths and product quality, Origin has successfully entered the supply chains of leading companies in the CNC tooling industry. Our laser five-axis machining centers have also been included in Guangdong Province’s Key Equipment Technology Catalog (First Set Program).

The laser processing market is becoming increasingly diversified, with both domestic and international players expanding across various segments, from laser sources to full laser systems. While large, well-established firms lead in technology and market share, many SMEs are thriving through innovation and market segmentation. In such a competitive environment, Origin Intelligence is placing greater emphasis on combining technological innovation with market demand. By offering differentiated products and services, we aim to meet the diverse needs of our customers and promote the sustainable development of the laser processing industry.

Derek Qian:

As a manufacturer and supplier of high-end laser CNC machine tools, Origin Intelligence offers a superior customer service system compared to imported brands, thanks to our localized service advantages. We provide comprehensive support across the entire customer journey—from pre-sales to in-sales to after-sales. We have established a well-developed after-sales service system and monitoring mechanism. With Foshan as our primary service hub, we are able to provide rapid support across our main operational regions, including South China, East China, and Southwest China. Our service team can respond within 2 hours and arrive on-site within 24 hours. For customers with process substitution requirements or equipment layout planning, we offer a dedicated pre-sales technical support team that delivers tailored, full-package technical solutions to meet specific production needs. Customer satisfaction has remained consistently high, thanks to our responsiveness, professionalism, and commitment to solving customer pain points in a timely and effective manner.

Derek Qian:

In terms of technological R&D, we will continue to steadily increase investment and actively explore new technologies and advanced processes—especially in the laser processing domain. This includes areas such as ultrafast laser precision machining and laser rotary-cutting control technologies. At the same time, we will focus on the development of industrial software deeply integrated with AI, particularly in the area of key algorithm design, to further enhance the intelligence level of our products. To address evolving industry trends and potential challenges, we will remain closely aligned with actual user needs, gradually expand our product offerings, and optimize product architecture. Our aim is to build intelligent, market-oriented laser CNC machining solutions that truly match customer expectations. In addition, we will actively seek collaboration across the industrial value chain, working together with upstream and downstream partners to create a more robust ecosystem and achieve coordinated growth. As for the future of Origin Intelligence, we will continue to deepen technological innovation, improve product performance, and deliver high-efficiency, high-quality products and services to our customers. We are fully committed to advancing toward our goal of becoming a leading global player in the CNC industry.

Source:Laser Manufacturing Review , April Issue

Disclaimer:

All content and images not originally created by this official account are reproduced from other media sources. They are shared for the purpose of information dissemination and knowledge sharing only. The views expressed do not necessarily reflect those of this account, and we do not guarantee the accuracy or authenticity of such content. Copyright belongs to the original authors. If any infringement is found, please contact us for prompt removal.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.