Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

OPMT Laser offers innovative auto parts processing solutions. CNC & laser tech ensures precision. Get a custom solution for your needs!

Key Takeaways:

Automotive parts processing demands a blend of precision, speed, and adaptability. From engine components to intricate interior elements, the manufacturing processes involved require advanced technological solutions. As someone who’s spent years in this field, I’ve seen firsthand how the right equipment can transform production lines, reducing waste and improving overall quality.

OPMT Laser specializes in developing advanced CNC systems and laser machine tools tailored for automotive parts processing. Their solutions address the challenges of modern automotive manufacturing, including the need for lightweighting, complex geometries, and diverse material processing.

Expert Insight: One crucial aspect I always emphasize is the importance of a system’s ability to handle different materials. Automotive parts range from aluminum alloys to high-strength steels, and a versatile machine is a game-changer.

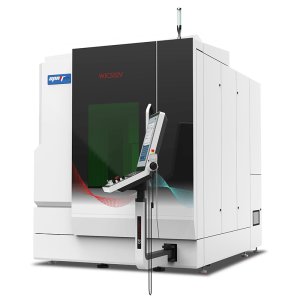

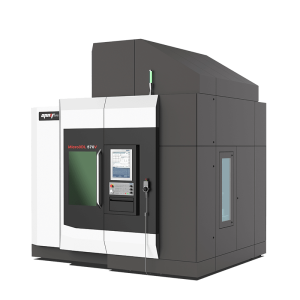

The 563V Vertical 5-Axis Machining Center stands out as a prime example of OPMT Laser’s capabilities. This machine is engineered for high precision and complex part machining, making it ideal for automotive components requiring intricate designs and tight tolerances.

Expert Tip: When evaluating machining centers, always consider the long-term benefits of reduced setup times and improved part accuracy. These factors significantly impact overall production efficiency.

OPMT Laser’s solutions cater to a broad spectrum of automotive applications. Whether it’s creating molds, machining engine components, or producing intricate interior parts, their technology offers enhanced precision and efficiency.

Laser technology plays a pivotal role in modern automotive manufacturing. OPMT Laser’s expertise in this area provides solutions for cutting, welding, and surface treatment, enhancing both the quality and efficiency of production processes.

Personal Anecdote: I recall a project where we used laser welding to join dissimilar metals in an exhaust system. The result was a lighter, more durable component that significantly improved the vehicle’s performance.

5-axis CNC machining is essential for producing complex automotive parts with high precision. OPMT Laser’s 5-axis machining centers, like the 563V, enable manufacturers to create intricate designs in a single setup, reducing errors and improving overall quality.

Expert Advice: For manufacturers dealing with complex parts, investing in a 5-axis machining center is a strategic move that pays off in the long run through increased efficiency and quality.

Integrating OPMT Laser’s solutions into existing automotive manufacturing processes requires careful planning and execution. Their team of experts works closely with manufacturers to ensure seamless integration and optimal performance.

OPMT Laser’s Automotive Parts Processing Solutions offer a comprehensive suite of advanced technologies for modern automotive manufacturing. From high-precision CNC systems to cutting-edge laser machine tools, their solutions are designed to enhance efficiency, improve quality, and meet the evolving demands of the automotive industry. The 563V Vertical 5-Axis Machining Center exemplifies their commitment to innovation and precision, making it a valuable asset for any automotive manufacturer.

WJC532V Water-guided Laser Five-axis Machining Center revolutionizes cutting and drilling for complex parts. Its water beam fiber technology achieves exceptional precision on super-hard materials, with a 100:1 cutting depth-to-width ratio and ±3μm accuracy. This versatile system delivers unparalleled surface quality for automotive and electronics manufacturing, setting new industry standards.

Micro3D L570V Five-axis Mould Texture Laser Processing Center revolutionizes surface texturing with its innovative CNC system. Combining 3D model simulation and intelligent splicing, it achieves micron-level precision, reducing processing time by 40%. This advanced machine tool delivers extraordinary texture effects for automotive and 3C electronics applications.

Micro3D L530V five-axis femtosecond laser machining center delivers unparalleled precision for 3D complex structures. With ≤±10μm accuracy and <1μm material removal, it excels in automotive and 3C electronics applications. This innovative system combines self-developed software with 40W infrared femtosecond laser technology, revolutionizing micro-nano processing and fine mold texturing.

L03A Oil Bit Contour Laser Machine revolutionizes PCD composite sheet processing with its self-developed CNC system. Featuring automatic loading for up to 100 pieces and a retractable dust-sealing structure, it ensures precision contour processing while minimizing thermal damage, ideal for automotive and electronics manufacturing.

Please fill in your contact information to download the PDF.