Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

OPMT Laser provides CNC & laser solutions for oil drilling, ensuring precision & durability. Learn about the L03A & more!

Key Takeaways:

The oil drilling industry demands components that can withstand extreme conditions and deliver consistent performance. The precision with which these components are manufactured directly impacts the efficiency and safety of drilling operations. At OPMT Laser, we understand these demands and provide solutions designed to meet and exceed them. With decades of expertise in CNC systems and laser technology, OPMT Laser supports the oil drilling sector by enabling the creation of parts with unparalleled accuracy and durability.

Our commitment goes beyond just providing machines; we offer comprehensive support to ensure our clients can optimize their manufacturing processes. This includes training, maintenance, and ongoing technical assistance, all aimed at maximizing the return on investment and enhancing operational capabilities. As someone deeply involved in the industry, I’ve seen firsthand how the right technology can transform operations, reducing downtime and improving overall productivity.

OPMT Laser offers a suite of advanced machines tailored for the unique needs of the oil drilling industry. Our technologies are designed to enhance the manufacturing process of critical components, ensuring they meet the stringent requirements of the sector.

These advanced technologies not only improve the quality of the components but also streamline the manufacturing process, reducing waste and saving time. In my experience, adopting these solutions can lead to a significant competitive advantage, allowing companies to deliver superior products more efficiently.

Oil drill bits are at the forefront of drilling operations, requiring them to be made with the highest accuracy. OPMT Laser’s L03A Oil Bit Contour Laser Machine is engineered to precisely shape and contour drill bits, enhancing their cutting capabilities and extending their operational life. The use of laser technology ensures minimal material waste and superior edge quality.

From my perspective, the ability to customize drill bits with such precision is a game-changer. It allows for the creation of specialized tools that can tackle unique geological challenges, improving drilling efficiency and reducing the risk of equipment failure.

Adopting OPMT Laser’s solutions can transform your manufacturing processes, leading to increased efficiency, reduced costs, and improved product quality. We provide comprehensive support to ensure a smooth integration, offering:

We pride ourselves on building long-term relationships with our clients, working as partners to ensure their success. This collaborative approach, combined with our cutting-edge technology, makes OPMT Laser the ideal choice for companies looking to elevate their manufacturing capabilities in the oil drilling industry.

To maximize the benefits of OPMT Laser solutions, consider these optimization tips:

By following these guidelines and partnering with OPMT Laser, you can transform your manufacturing processes and achieve new levels of success in the oil drilling industry.

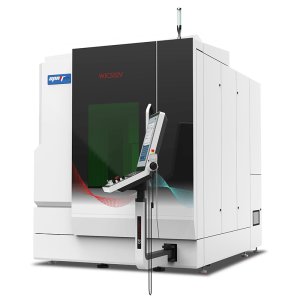

WJC532V Water-guided Laser Five-axis Machining Center revolutionizes cutting and drilling for complex parts. Its water beam fiber technology achieves exceptional precision on super-hard materials, with a 100:1 cutting depth-to-width ratio and ±3μm accuracy. This versatile system delivers unparalleled surface quality for automotive and electronics manufacturing, setting new industry standards.

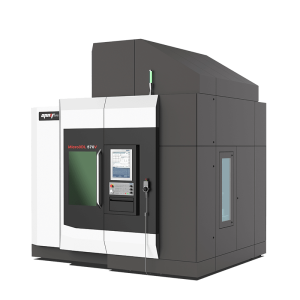

Micro3D L570V Five-axis Mould Texture Laser Processing Center revolutionizes surface texturing with its innovative CNC system. Combining 3D model simulation and intelligent splicing, it achieves micron-level precision, reducing processing time by 40%. This advanced machine tool delivers extraordinary texture effects for automotive and 3C electronics applications.

Micro3D L530V five-axis femtosecond laser machining center delivers unparalleled precision for 3D complex structures. With ≤±10μm accuracy and <1μm material removal, it excels in automotive and 3C electronics applications. This innovative system combines self-developed software with 40W infrared femtosecond laser technology, revolutionizing micro-nano processing and fine mold texturing.

L03A Oil Bit Contour Laser Machine revolutionizes PCD composite sheet processing with its self-developed CNC system. Featuring automatic loading for up to 100 pieces and a retractable dust-sealing structure, it ensures precision contour processing while minimizing thermal damage, ideal for automotive and electronics manufacturing.

Please fill in your contact information to download the PDF.