Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

OPMT Laser offers advanced, precise CNC & laser solutions for medical devices, implants & surgical tools. Get expert support & custom solutions today!

Key Takeaways

The medical industry demands the highest levels of precision and quality in manufacturing. At OPMT Laser, we understand these critical requirements and provide advanced CNC systems and laser machine tools designed specifically for the precision medical industry. Our solutions empower manufacturers to produce intricate components with exceptional accuracy, repeatability, and surface finish.

Modern medicine relies on increasingly complex and precise devices, from minimally invasive surgical tools to advanced implantable components. These devices often require intricate geometries, tight tolerances, and specialized materials. OPMT Laser’s technology rises to these challenges, offering capabilities that traditional machining methods simply cannot match.

We provide solutions for:

OPMT Laser leverages cutting-edge technologies to deliver unparalleled precision and performance. Our key offerings include:

Our LightMUT 750V Laser Grinding and Milling Machining Center is a prime example of our commitment to providing comprehensive solutions.

The medical industry utilizes a wide array of materials, each with unique properties and machining requirements. OPMT Laser’s machines are designed to handle a diverse range of materials, including:

Expert Tip: When selecting a machine, consider the range of materials you’ll be working with and ensure the machine is equipped with the appropriate laser source and tooling.

We also understand the growing importance of nylon 12 in medical applications, and our machines are well-suited to process this versatile material. We’ve seen firsthand how proper material selection can improve device performance and patient outcomes.

OPMT Laser is more than just a machine tool provider; we are a partner in your manufacturing success. We offer:

Anecdote: I recall working with a client who was struggling to produce a complex spinal implant. By implementing our 5-axis machining solution and optimizing their tooling, we were able to reduce their cycle time by 40% and improve the implant’s surface finish, ultimately leading to better patient outcomes.

Final Thought: The medical industry is constantly evolving, and OPMT Laser is committed to staying at the forefront of precision manufacturing technology. Contact us today to learn how we can help you achieve your manufacturing goals and improve patient outcomes.

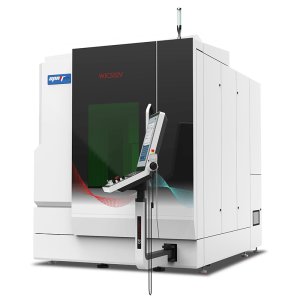

WJC532V Water-guided Laser Five-axis Machining Center revolutionizes cutting and drilling for complex parts. Its water beam fiber technology achieves exceptional precision on super-hard materials, with a 100:1 cutting depth-to-width ratio and ±3μm accuracy. This versatile system delivers unparalleled surface quality for automotive and electronics manufacturing, setting new industry standards.

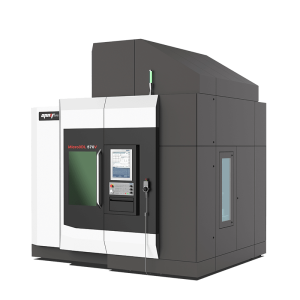

Micro3D L570V Five-axis Mould Texture Laser Processing Center revolutionizes surface texturing with its innovative CNC system. Combining 3D model simulation and intelligent splicing, it achieves micron-level precision, reducing processing time by 40%. This advanced machine tool delivers extraordinary texture effects for automotive and 3C electronics applications.

Micro3D L530V five-axis femtosecond laser machining center delivers unparalleled precision for 3D complex structures. With ≤±10μm accuracy and <1μm material removal, it excels in automotive and 3C electronics applications. This innovative system combines self-developed software with 40W infrared femtosecond laser technology, revolutionizing micro-nano processing and fine mold texturing.

L03A Oil Bit Contour Laser Machine revolutionizes PCD composite sheet processing with its self-developed CNC system. Featuring automatic loading for up to 100 pieces and a retractable dust-sealing structure, it ensures precision contour processing while minimizing thermal damage, ideal for automotive and electronics manufacturing.

Please fill in your contact information to download the PDF.