Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

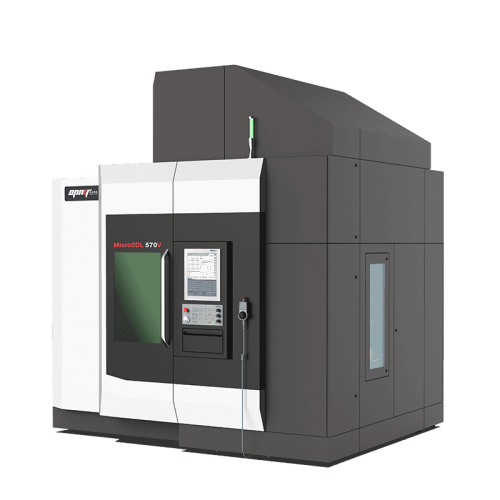

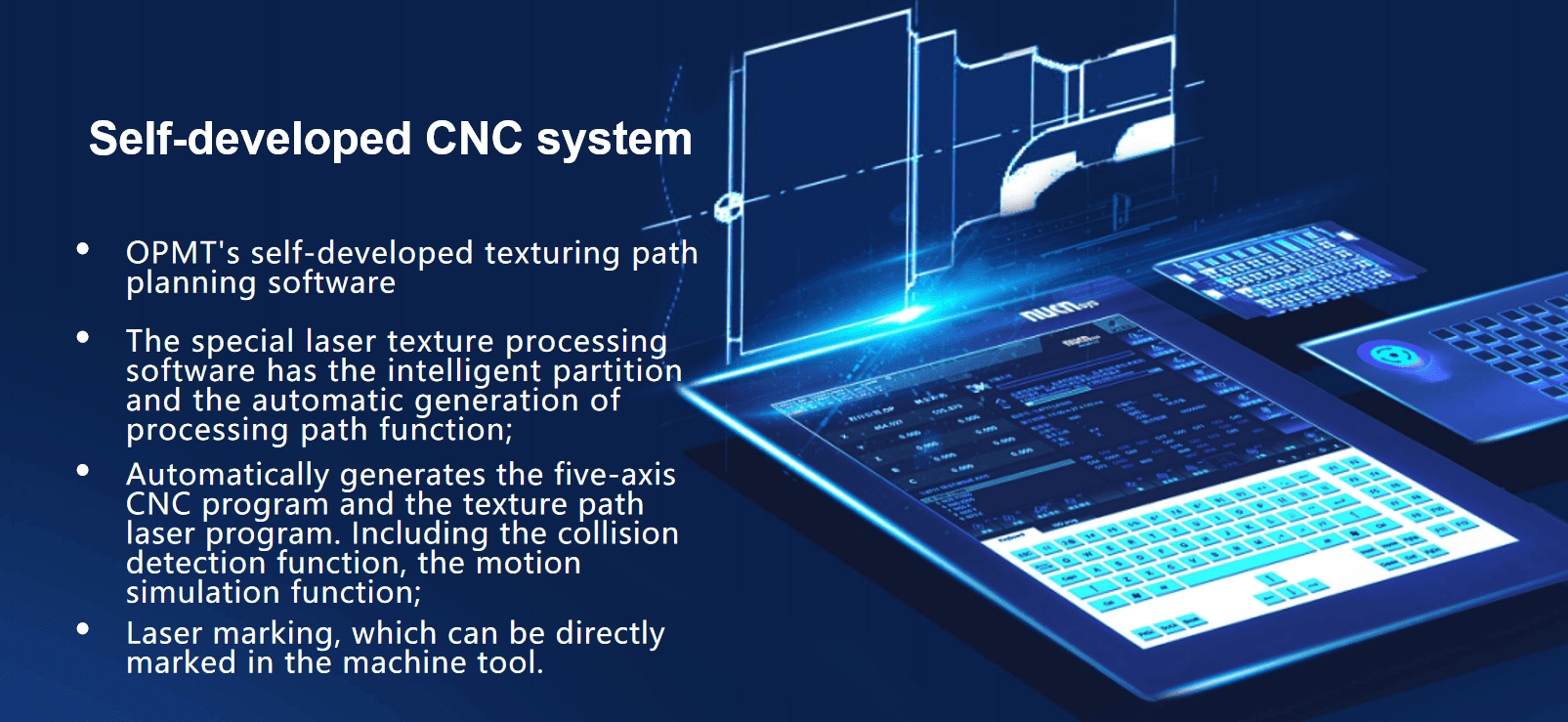

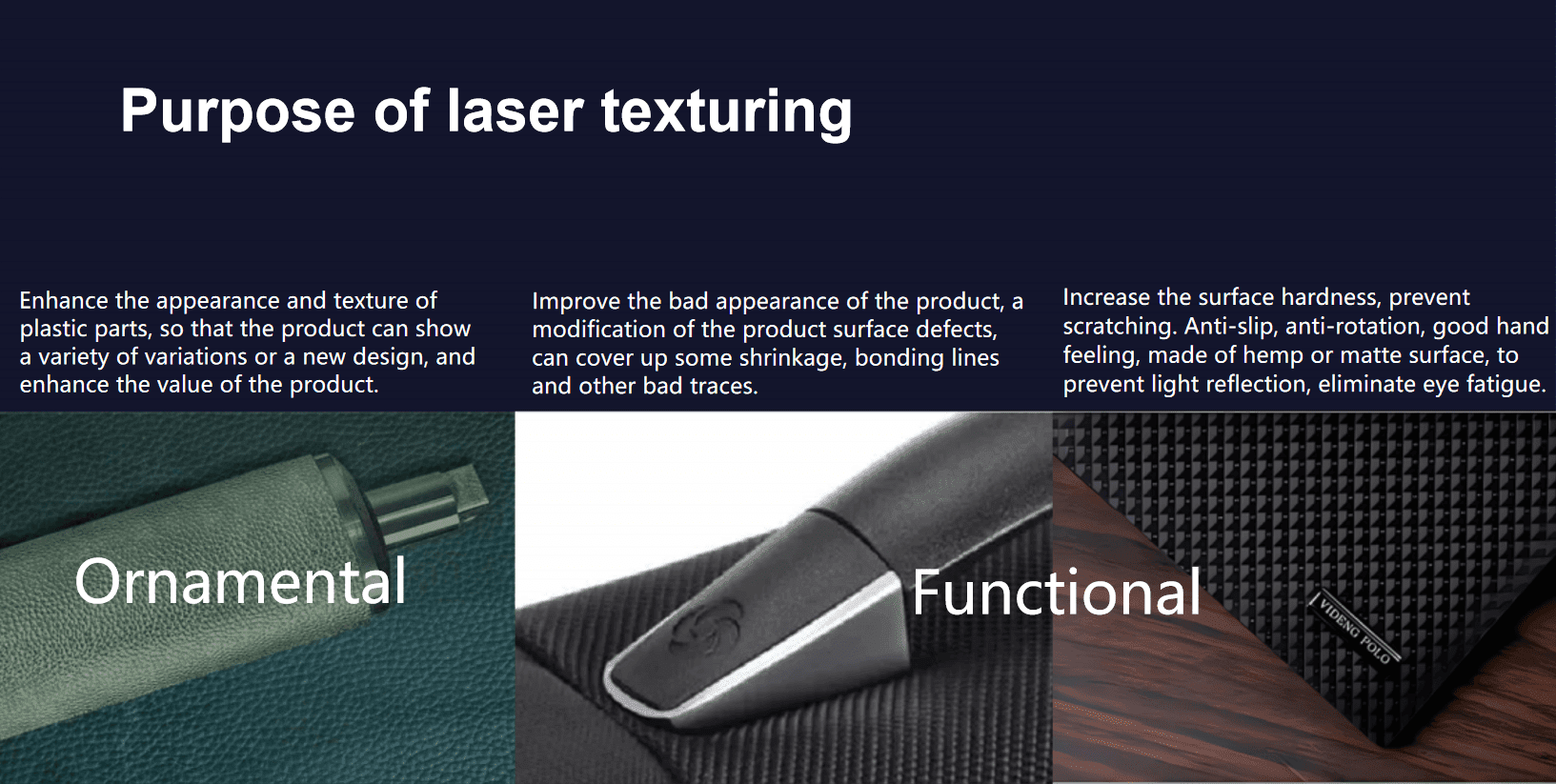

Micro3D L570V Five-axis Mould Texture Laser Processing Center revolutionizes surface texturing with its innovative CNC system. Combining 3D model simulation and intelligent splicing, it achieves micron-level precision, reducing processing time by 40%. This advanced machine tool delivers extraordinary texture effects for automotive and 3C electronics applications.

Micro3D L570V five-axis laser texture processing machine is a mold texture laser processing machine independently developed by Yuandian Intelligence. It uses nanosecond laser (compatible with femtosecond laser) fine processing capabilities, and cooperates with high-precision galvanometer to achieve precise engraving and processing on free-form surfaces. Combining the five-axis machine tool and the self-developed special laser processing software, it can achieve precision processing of periodic structures and various complex textures on free-form surfaces.

Please fill in your contact information to download the PDF.