Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Lasers have transformed numerous industries, becoming essential tools in healthcare, manufacturing, and telecommunications. With the global laser market projected to exceed $14 billion by 2026, the significance of laser technology in our everyday lives is undeniable.

If you’re looking to enhance your projects or business with cutting-edge laser solutions, OPMT Laser is here to guide you. This article will unveil the top laser types of 2025 and explore their key applications across various sectors. Whether you’re just starting out or are a seasoned expert, you’ll find valuable insights tailored to your needs.

Are you excited to expand your understanding of laser technology? Let’s dive into this enlightening journey together!

Lasers can be categorized into several types based on their gain medium, each with unique characteristics and applications. Understanding these distinctions is crucial for selecting the right laser for specific tasks.

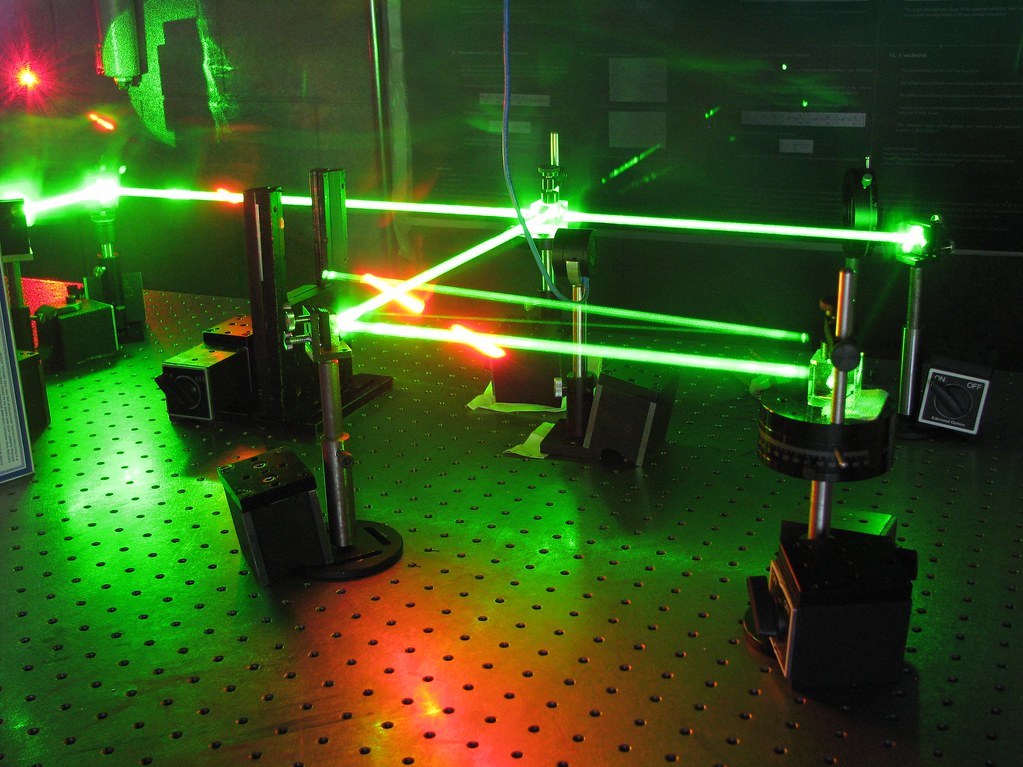

Fiber lasers utilize optical fibers as the gain medium, offering high efficiency and precision. They are widely employed in industrial settings for cutting and welding metals due to their ability to produce fine features with high-quality edges. Their compact design also makes them suitable for various applications, from medical treatments to telecommunications. In fact, fiber lasers have become increasingly popular due to their lower maintenance costs compared to traditional laser systems.

Dye lasers use organic dyes as the gain medium and can generate a broad range of wavelengths (400-1000 nm). They are often employed in spectroscopy and medical applications where specific wavelengths are essential. Their tunability allows for versatility in research settings. For example, dye lasers can be adjusted to emit different colors of light, making them useful in various scientific experiments.

Compact and efficient, semiconductor lasers (or diode lasers) are prevalent in everyday devices such as optical disc drives, barcode scanners, and telecommunications equipment. Their high power-to-cost ratio makes them increasingly popular across various industries, including consumer electronics and medical devices. Did you know that diode lasers have revolutionized the way we read CDs and DVDs? Their efficiency has made data storage more accessible than ever before.

These diverse types of lasers not only highlight the technological advancements but also showcase their significant impact across multiple sectors—from healthcare to manufacturing—demonstrating their essential role in modern technology.

Lasers have become essential tools across various sectors, including medicine, manufacturing, communication, and entertainment. Their unique properties enable a wide range of applications that enhance efficiency and effectiveness in numerous fields.

The diverse applications of laser technology not only showcase its versatility but also highlight its significant impact across multiple sectors. As advancements continue, we can expect even more innovative uses that will further integrate lasers into our daily lives.

The versatility of laser technology is revolutionizing precision and efficiency across diverse industries. With the global laser market expected to exceed $14 billion by 2026, understanding the various laser types and their applications is more crucial than ever.

By exploring the leading laser technologies of 2025, you can significantly improve patient outcomes in healthcare or optimize production lines in manufacturing. Imagine the possibilities these advanced tools could unlock for your projects!

As you begin to harness the power of laser technology, consider how it can spark innovation in your field. What remarkable advancements could you achieve with the right solutions from OPMT Laser? Keep discovering how our offerings can empower your journey toward excellence!

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.