Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

Guangdong Original Point Intelligent Technology Co., Ltd. (Original Point Intelligent), established in 2015, is a National Specialized and Innovative “Little Giant” Enterprise and National Intellectual Property Advantage Enterprise. The company specializes in the research, development, manufacturing, and technical services of five-axis and multi-axis linkage CNC systems, providing intelligent factory solutions centered on laser CNC machine tools as core equipment.

Original Point Intelligent has constructed a comprehensive core technology system integrating “high-end CNC systems + ultrafast lasers + process software,” proposing the concept of “full laser manufacturing” processing. In terms of technological innovation, the company has accumulated 231 authorized patents (including 68 invention patents) and participated in formulating three national standards.

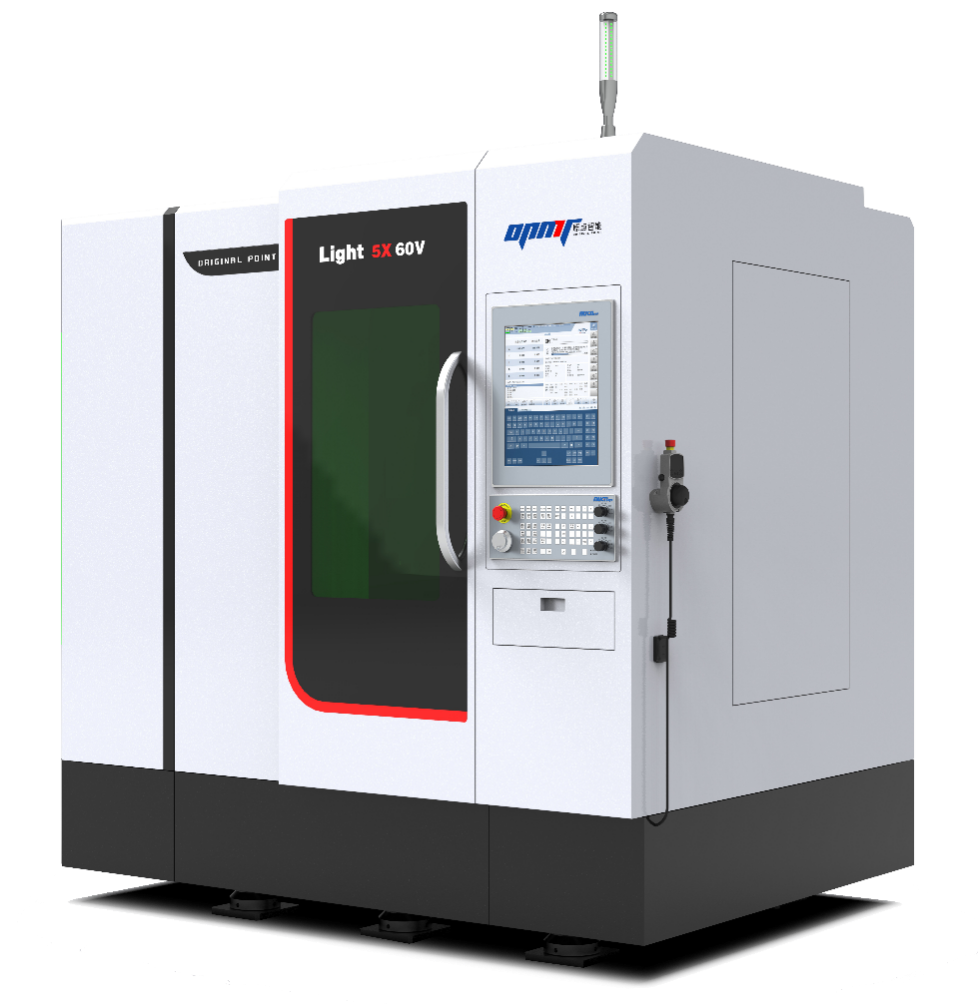

The company’s Light 5X 60V five-axis laser machining center has been awarded the 2024 Top Ten Independent Innovation title by the China Machine Tool & Tool Builders’ Association.

The Light 5X 60V five-axis laser machining center is professional equipment designed for high-precision processing of medium to large-scale complex curved surfaces. It can complete efficient, high-quality processing of precision superhard tools, suitable for applications in 3C electronics, aerospace, automotive, and other industries.

Combined with dedicated processing software, the system can perform five-axis linkage precision processing for complex profiles and contours of superhard materials, carbide, and superhard coating tools. The machine tool features automatic tool clamping and releasing functions and can be equipped with robots, gantry systems, and other automatic loading/unloading modules to achieve unmanned intelligent production.

Original Point Intelligent independently developed multi-axis linkage CNC systems and industrial CAM software to solve the deep integration challenges between software and laser processing machine tools. Addressing the technical difficulty of smooth transitions between end cutting edges and side cutting edges of complex structured tools, the research team developed proprietary controllable laser processing CAM software from fundamental algorithms.

Key intelligent features include:

Original Point Intelligent overcame energy drift and poor spot positioning accuracy issues caused by the inability to use mechanical positioning in laser processing. The company developed a high-precision laser positioning system through three core technological breakthroughs:

Original Point Intelligent developed high-precision laser processing technology specifically for complex-shaped PCD tools, solving processing challenges of large curvatures, multiple cutting edges, and narrow cutting bands, significantly improving PCD tool processing efficiency and quality.

Through innovative “full laser” manufacturing processes, Original Point Intelligent achieved breakthrough performance in PCD tool processing: contour accuracy ≤8μm, surface roughness <0.3μm, maximum cutting edge count of 180, and minimum cutting edge width of 10μm. Compared to traditional grinding processes, single-piece processing time was reduced from 675 minutes to 85 minutes, improving overall processing efficiency by nearly 8 times.

The Light 5X 60V five-axis laser machining center has achieved industrial applications in superhard tools, aerospace, and other fields, serving benchmark enterprises such as Zhuzhou Cemented Carbide Cutting Tools Co., Ltd. With the rapid development of 3C electronics, automotive manufacturing, aerospace, and other industries, the processing demand for high-performance difficult-to-machine materials such as superhard materials, carbide, and coated carbide will continue to increase.

Customer feedback indicates significant improvements in precision processing production capabilities. The equipment resolved previous issues of insufficient accuracy and low efficiency in processing complex contour tools, enabling customers to undertake more complex part processing tasks. Workpieces can complete rough and finish processing in a single setup, saving considerable labor and time costs.

Original Point Intelligent will continue launching more competitive products. In technological innovation, the company will focus on deep integration of ultrafast lasers with five-axis linkage and CNC systems. For market expansion, the company plans to deepen strategic cooperation with international giants and establish technical service centers in Europe and America. In industrial ecosystem development, Original Point Intelligent will collaborate with leading enterprises in 3C, automotive, mold, and other industries to build ecological alliances, driving the company’s transformation from single equipment supply to full industrial chain empowerment.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.