Schedule a Visit

Regardless of whether you require general advice or specific support, we are happy to help you.

Regardless of whether you require general advice or specific support, we are happy to help you.

All News

Share

OPMT’s comprehensive laser processing portfolio represents a paradigm shift in precision manufacturing, delivering advanced multi-axis CNC laser machining systems that address critical challenges across automotive, 3C electronics, aerospace, and medical device industries. Founded in 2015, Guangdong Original Point Intelligent Technology Co., Ltd. has established itself as a leading manufacturer of innovative laser processing solutions with ISO 9001, ISO 14001, and ISO 45001 certifications.

The flagship Light 5X 60V and Light 5X 40V represent the pinnacle of precision laser machining technology, specifically engineered for processing superhard materials including PCD, CBN, CVD diamonds, and advanced ceramics.

Technical Specifications Comparison:

| Parameter | Light 5X 60V | Light 5X 40V |

|---|---|---|

| Travel Range (X×Y×Z) | 600×250×300mm | 400×250×300mm |

| Positioning Accuracy | 0.005mm | 0.005mm |

| Repeat Positioning Accuracy | 0.003mm | 0.003mm |

| Workbench Load Capacity | 300kg | 100kg |

| Laser Specifications | 100W, 1ns pulse width | 100W, 1ns pulse width |

| Maximum Tool Weight | 25kg | 8kg |

| Rapid Traverse Speed | 30 m/min | 30 m/min |

Both systems utilize linear motor drives on XYZ axes combined with high-precision torque motors for rotational axes, enabling RTCP 5-axis linkage capabilities essential for complex contour machining.

Micro3D L570V Mold Texturing Laser Machine

The Micro3D L570V revolutionizes surface texturing applications with 0.01mm accuracy, supporting both nanosecond and femtosecond laser configurations. This system enables unlimited pattern design capabilities while maintaining environmental sustainability through chemical-free processing.

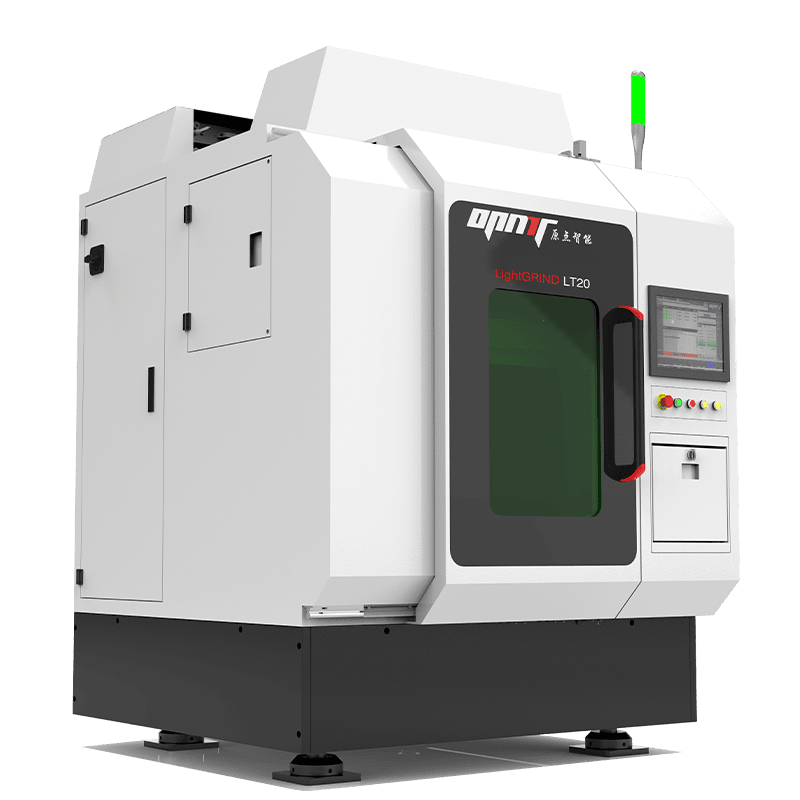

LightGRIND Series: Advanced Laser Grinding Solutions

OPMT’s laser processing technology delivers transformative results in automotive tooling applications. PCD step-forming milling cutters processed using the Light 5X series achieve:

Traditional EDM limitations including chip formation, wire skipping on non-conductive materials, and thermal damage are completely eliminated through laser processing.

The precision requirements of 3C electronics manufacturing are addressed through specialized laser processing capabilities:

Advanced ultrafast laser processing capabilities support critical aerospace and medical applications:

Cost Comparison Analysis:

| Parameter | Traditional EDM | OPMT Laser Processing |

|---|---|---|

| Floor Space Required | 10m² | 6m² |

| Energy Consumption | 4.5 kWh/8hr | 2.5 kWh/8hr |

| Consumables Cost | 10 Yuan/hr | 0 Yuan/hr |

| Total Monthly Cost | 4,190 Yuan | 1,956 Yuan |

| Processing Speed | 24 hours/piece | 8 hours/piece |

Material Processing Performance:

| Material | Removal Rate | Surface Roughness | Precision Tolerance |

|---|---|---|---|

| PCD | 3.2 mm³/s | 0.12μm Ra | ±0.003mm |

| CBN | 2.8 mm³/s | 0.15μm Ra | ±0.003mm |

| Silicon Carbide | 1.5 mm³/s | 0.25μm Ra | ±0.005mm |

| Ceramics | Variable | 20% of operating revenue |

All OPMT laser systems integrate self-developed universal CNC platforms offering:

OPMT’s commitment to technological advancement is demonstrated through:

OPMT’s comprehensive laser solutions deliver measurable advantages across multiple performance metrics:

Precision Improvements: Sub-micron positioning accuracy (0.005mm) with exceptional repeatability (0.003mm) enables processing of the most demanding precision components.

Efficiency Gains: Processing speeds up to 300% faster than traditional EDM methods, combined with eliminated consumable costs, deliver superior total cost of ownership.

Environmental Benefits: Chemical-free processing with minimal energy consumption supports sustainable manufacturing initiatives while maintaining the highest quality standards.

Technological Innovation: Advanced multi-axis laser processing capabilities, combined with intelligent CNC control systems, position OPMT at the forefront of Industry 4.0 manufacturing transformation.

The integration of proven laser technologies with comprehensive service support makes OPMT’s solutions the definitive choice for manufacturers seeking to advance their precision manufacturing capabilities while achieving operational excellence in 2025 and beyond.

Disclaimer

This content is compiled by OPMT Laser based on publicly available information for reference only; mentions of third-party brands and products are for objective comparison and do not imply any commercial association or endorsement.

Explore the world of CNC machining as we compare 3-axis and 5-axis technologies. From basic operations to complex geometries, find out which machine suits your manufacturing needs in 2025.

Explore OPMT’s proven 5-phase ODM process for custom laser systems. ISO-certified manufacturing, ±0.003mm precision, IP protection. Submit project requirements today.

Looking for the best 5-axis CNC machining center suppliers? Check our top 10 list for expert insights and find the perfect fit for your needs!

Explore the top 10 laser metal cutting machines of 2025, featuring industry leaders like Trumpf, Bystronic, and OPMT Laser. Compare cutting-edge technology, precision, and efficiency to find the perfect solution for your manufacturing needs.

Please fill in your contact information to download the PDF.