Welcome to Original Point Intelligent Technology

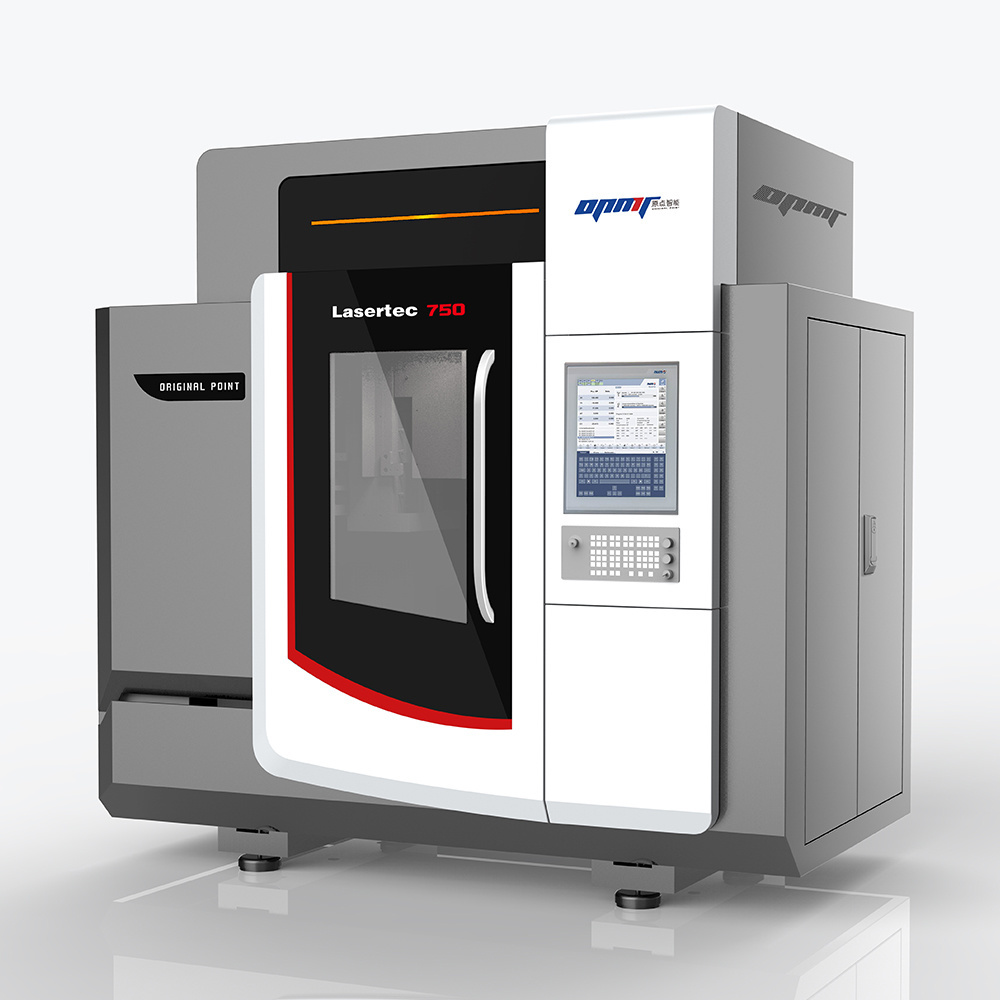

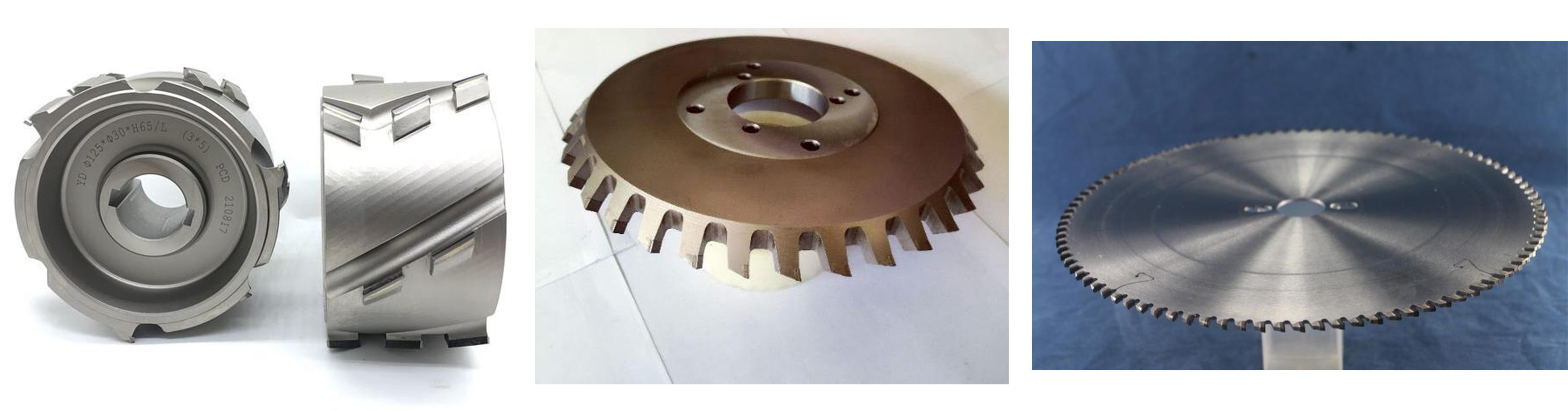

Woodworking Laser Machining Applications

Through the use of laser precision cutting processing technology, production efficiency and product quality can be effectively improved. At the same time, it can also reduce production costs and environmental pollution. Therefore, laser precision cutting processing technology is a very efficient and sustainable processing method, and laser machine tools are especially advantageous for PCD woodworking tools.

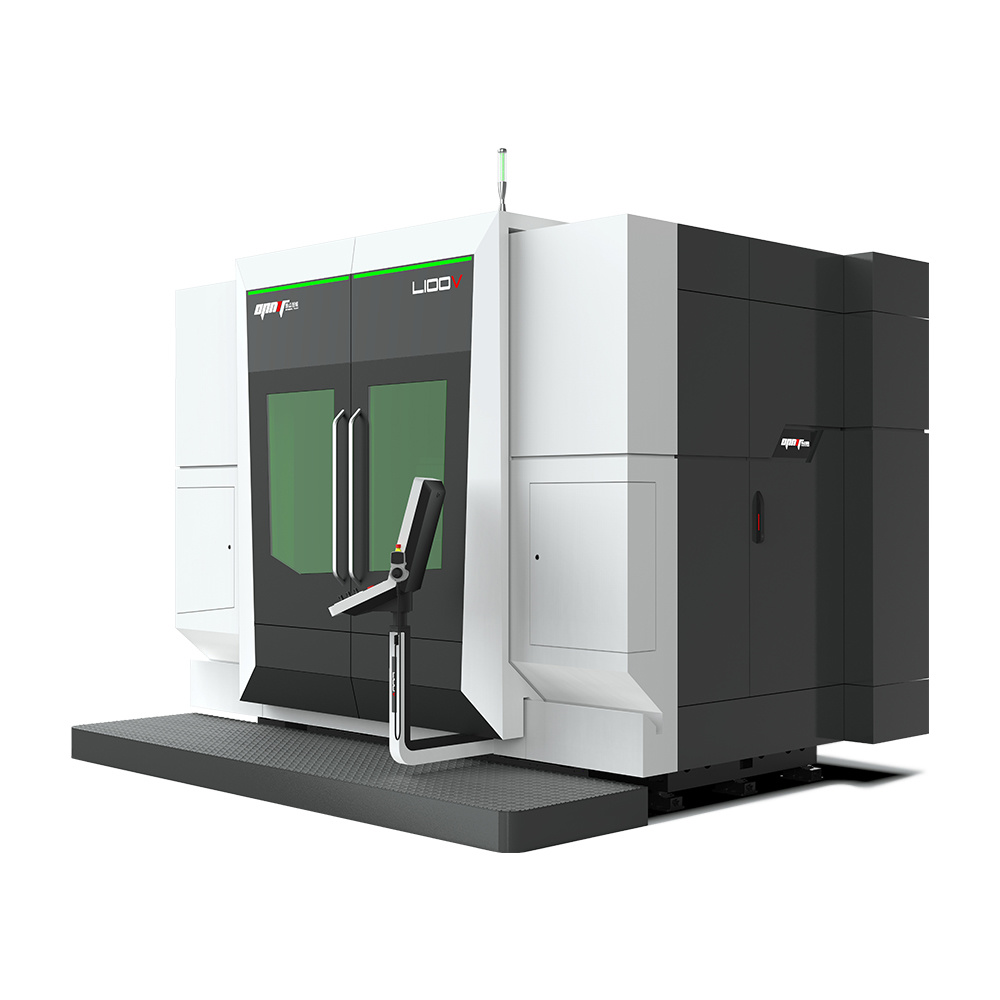

1.The machine is made of natural marble with stable structure, good rigidity, high accuracy and strong reliability;

2.The linear axes are driven by linear motors, while the rotation axes are driven by torque motors. Detected with the full closed-loop grating scale, it has high positioning accuracy and fast dynamic response;

3. Optimize the gear mechanism, using high-precision interpolation to make the positioning of each blade tooth more accurate, with high-precision probe to automatically correct the blade tooth welding error;

4. One clamping can complete the roughing and finishing of the top and side of the saw blade, reducing the cumulative error of the process.

- 2-3 times more efficient

- No need to worry about conductivity

- Long life and low power consumption

- More environmentally friendly and cleaner

- Safe and reliable production

- Any tooth shape can be processed

- Free permanent software upgrades

- Cost savings at origin

Copyright © 2024 Guangdong Original Point Intelligent Technology Co., Ltd. All Right Reserved SEO Business license Powered by:300.cn