Welcome to Original Point Intelligent Technology

Apr 18,2024

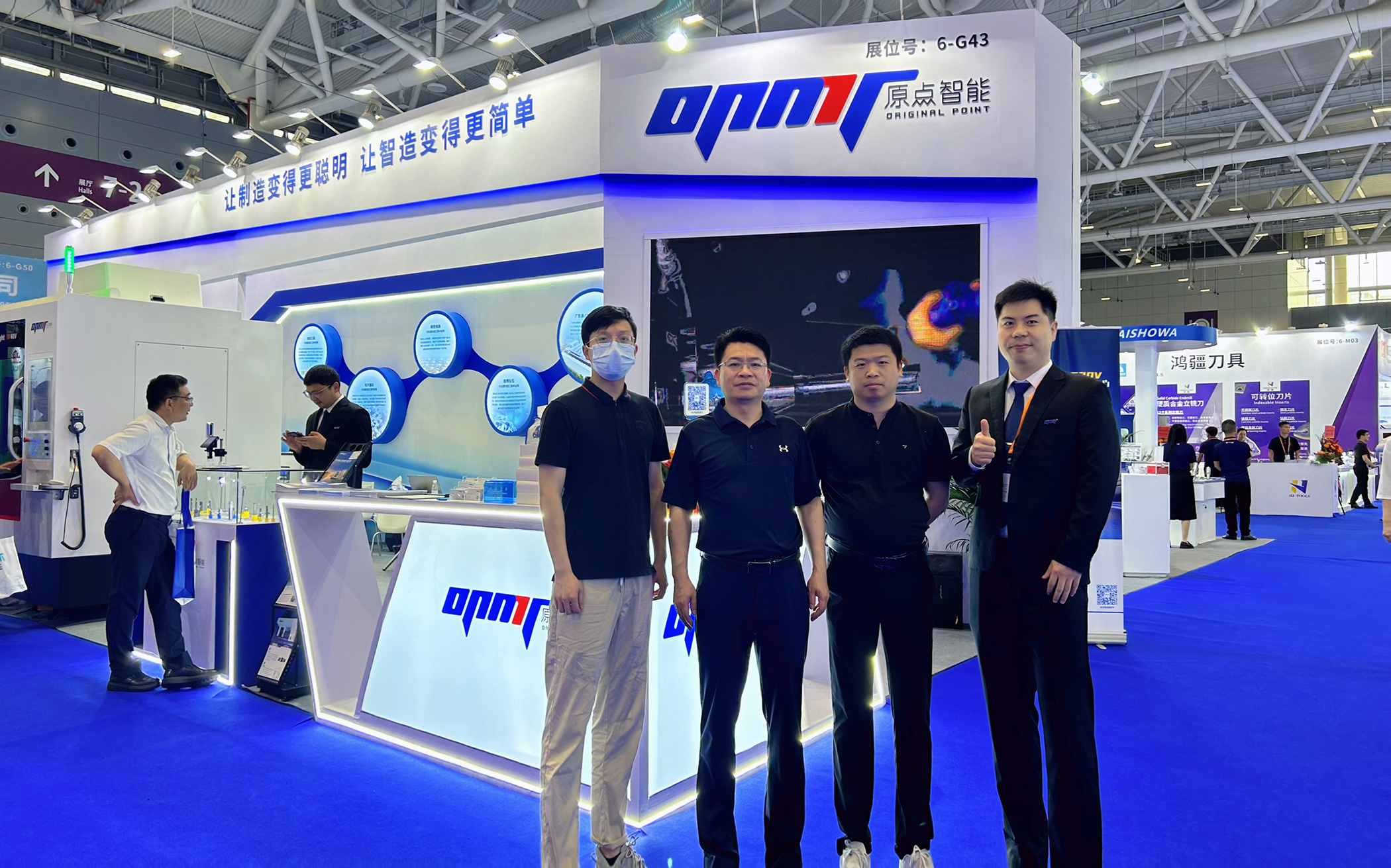

CCMT Shanghai 2024, origin intelligent all-laser parts manufacturing leads a new era of intelligent manufacturing

Previously at The 13th China CNC Machine Tool Exhibition (CCMT 2024),

OPMT China represents the new productivity of laser manufacturing. In the field of artificial intelligence and automation technology, Origin Intelligence actively embraces "AI empowerment" and focuses on intelligent laser processing parameter optimization, intelligent visual quality inspection, intelligent R&D innovation in processing path planning and other directions has achieved preliminary results in intelligent automation solutions, showing a good prototype of development.

OPMT China has always adhered to the corporate mission of "to make manufacturing easier and smarter ". It has always focused on the R&D and manufacturing of five-axis and above multi-axis linkage CNC systems, and is committed to laser CNC Machine tools are the core equipment to create smart factory solutions. At this CCMT2024 exhibition, we brought the latest technology and applications of all-laser parts manufacturing, allowing the audience to experience the charm and power of laser technology for themselves!

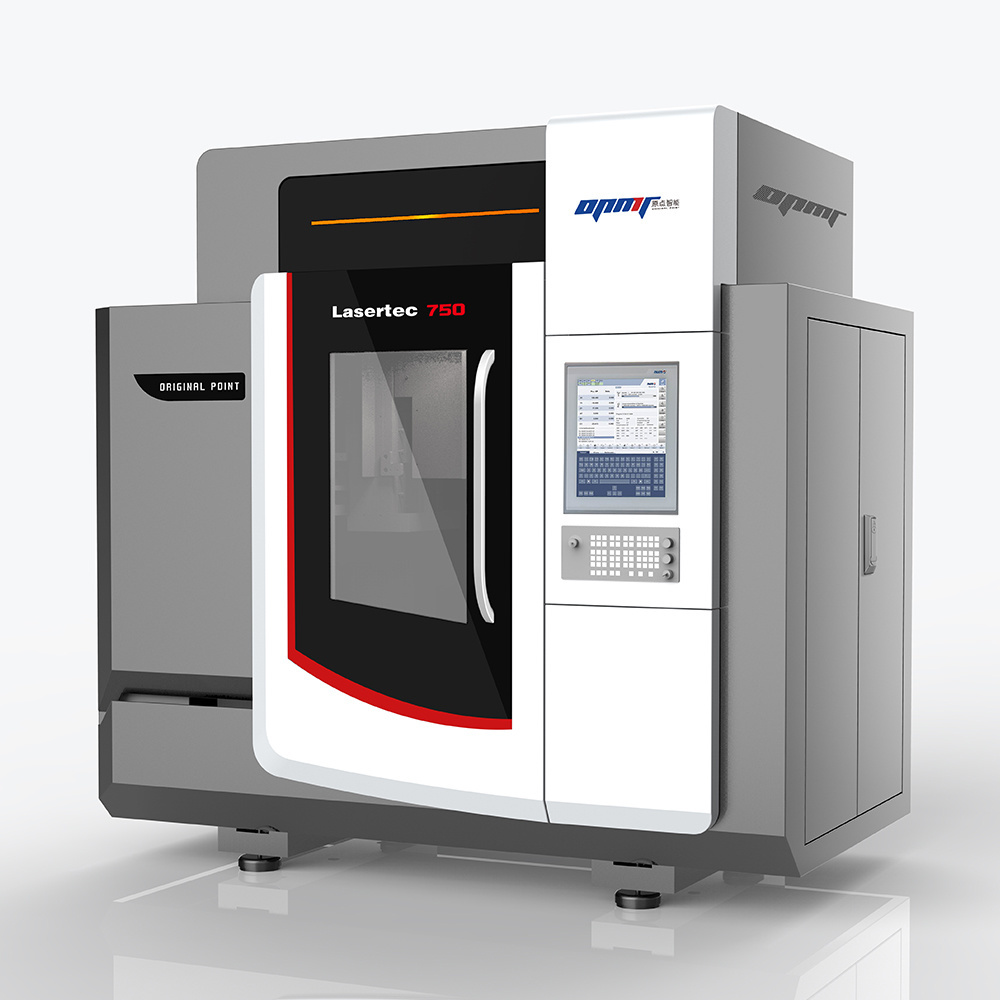

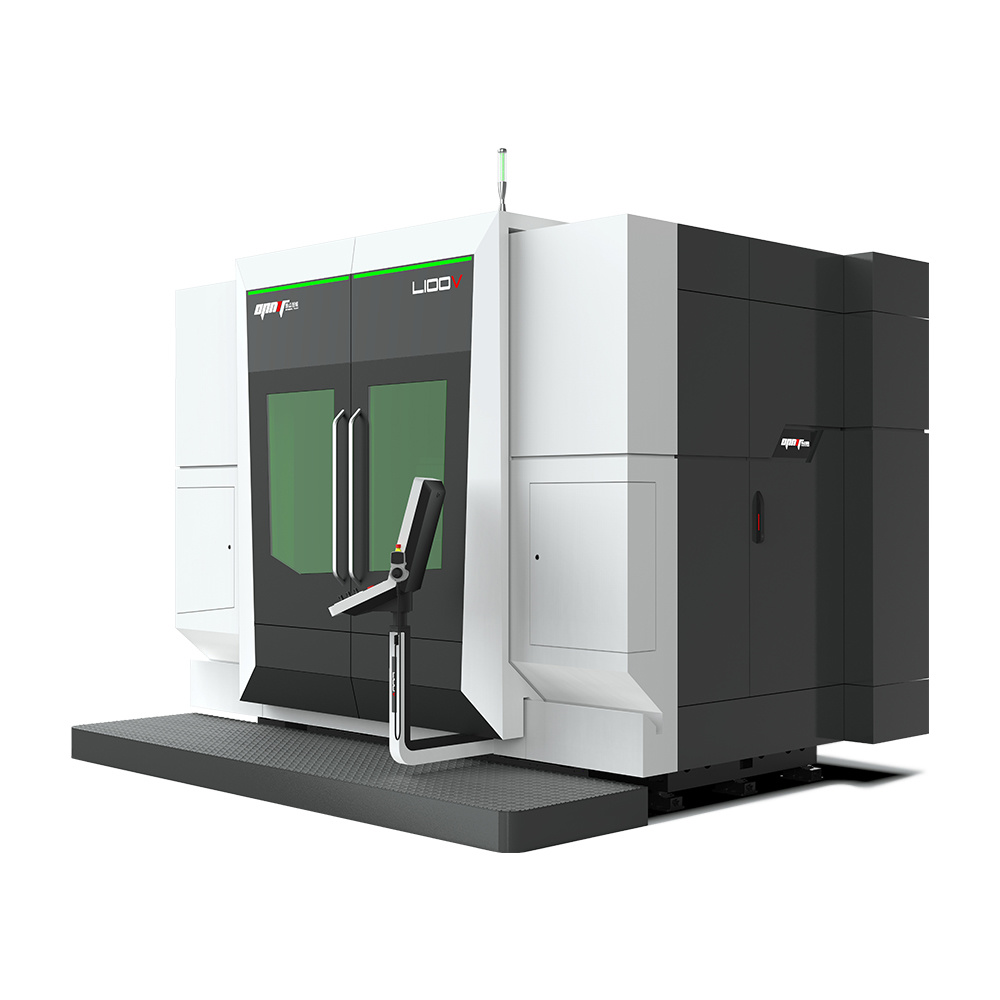

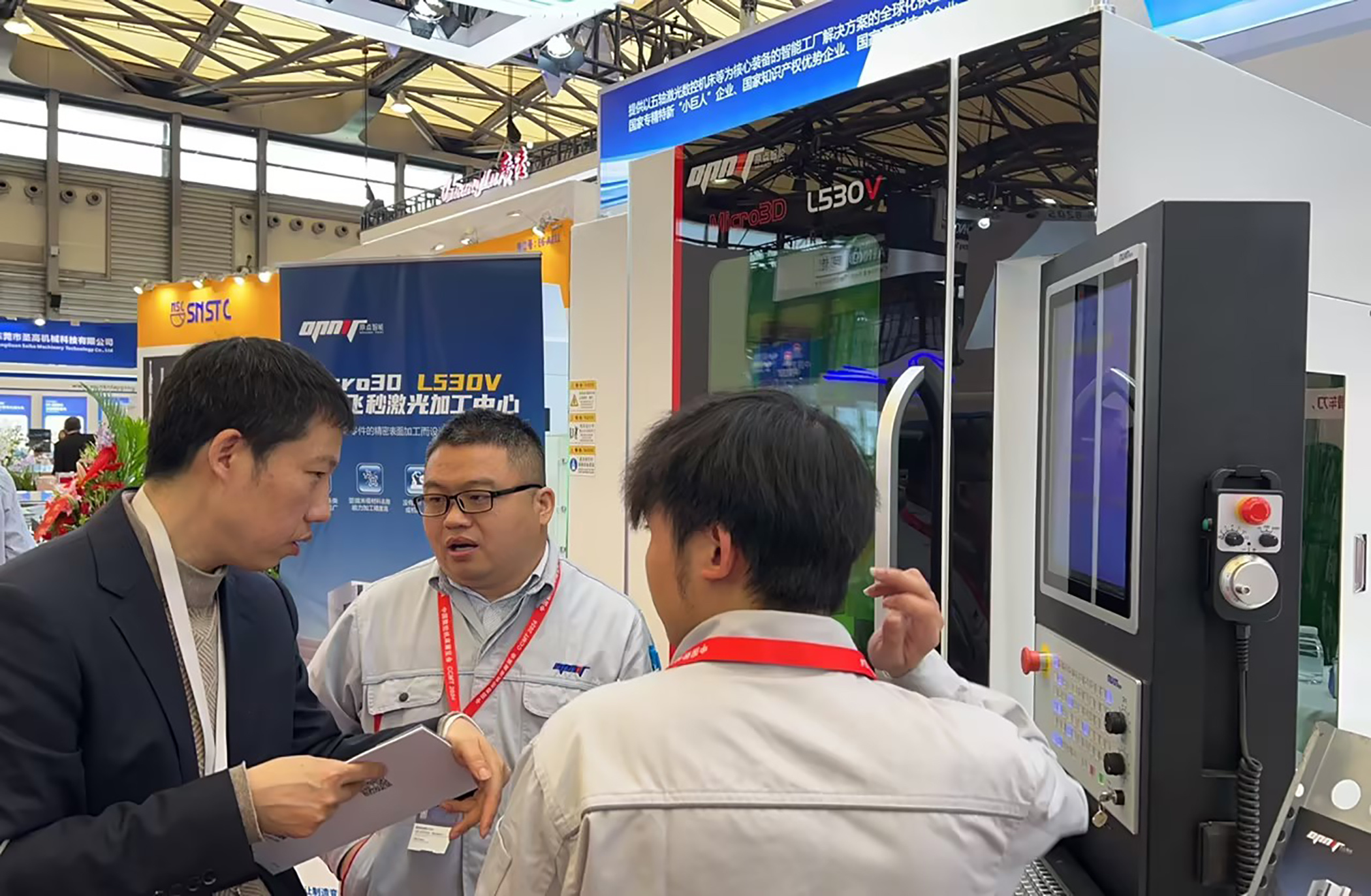

Micro3D L530V

The Micro3DL530V five-axis femtosecond laser processing center independently developed and designed by OPMT China is equipped with laser power control software and a high-precision three-dimensional online measurement control system. It can measure the machined surface of parts in real time during the manufacturing process and make adjustments based on the measurement results. The laser power and processing path are adjusted and optimized in real time to ensure processing accuracy;

Successfully developed laser power control software, which can establish a process parameter library mapping the relationship between laser power and material ablation depth. Relying on the process parameter library and high-precision three-dimensional online measurement and control system, ultra-fast femtosecond laser high-precision controllable processing was developed. technology, bringing more efficient, more precise and more reliable solutions to the laser processing industry, and continuously promoting industrial upgrading and innovative development.

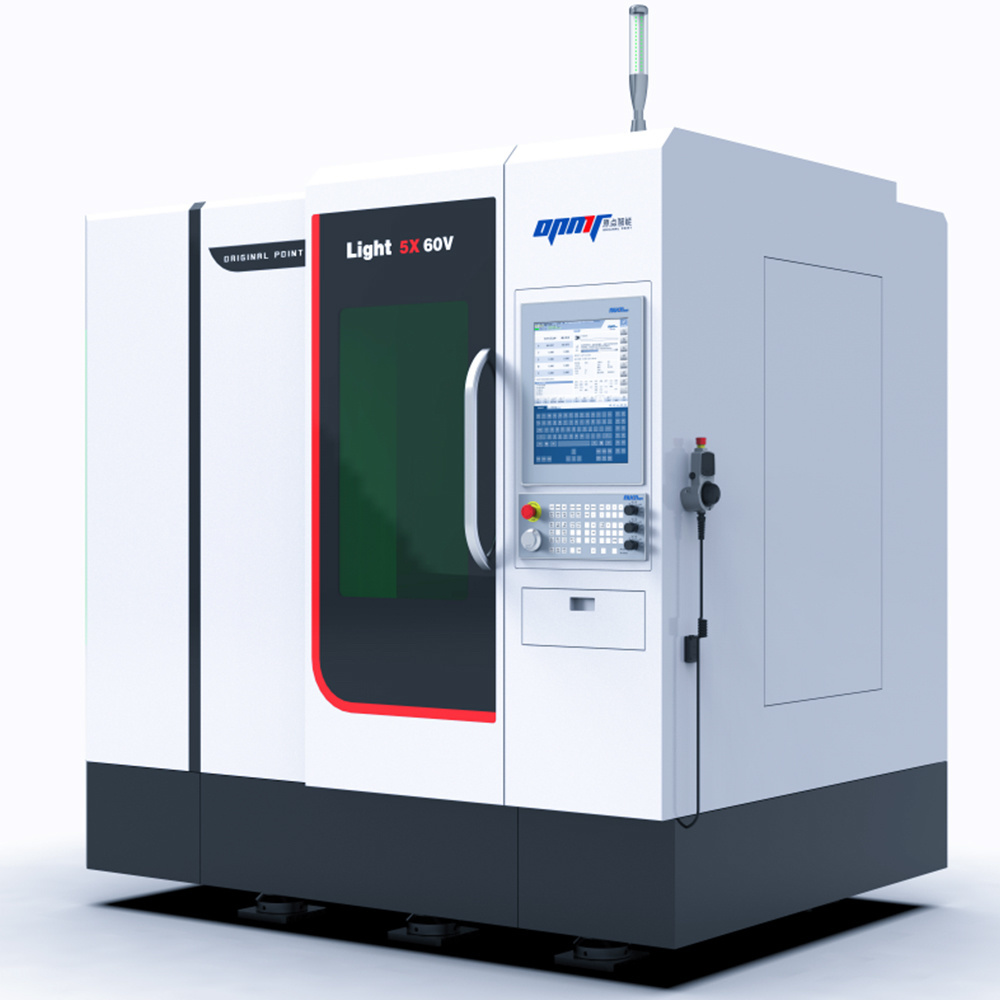

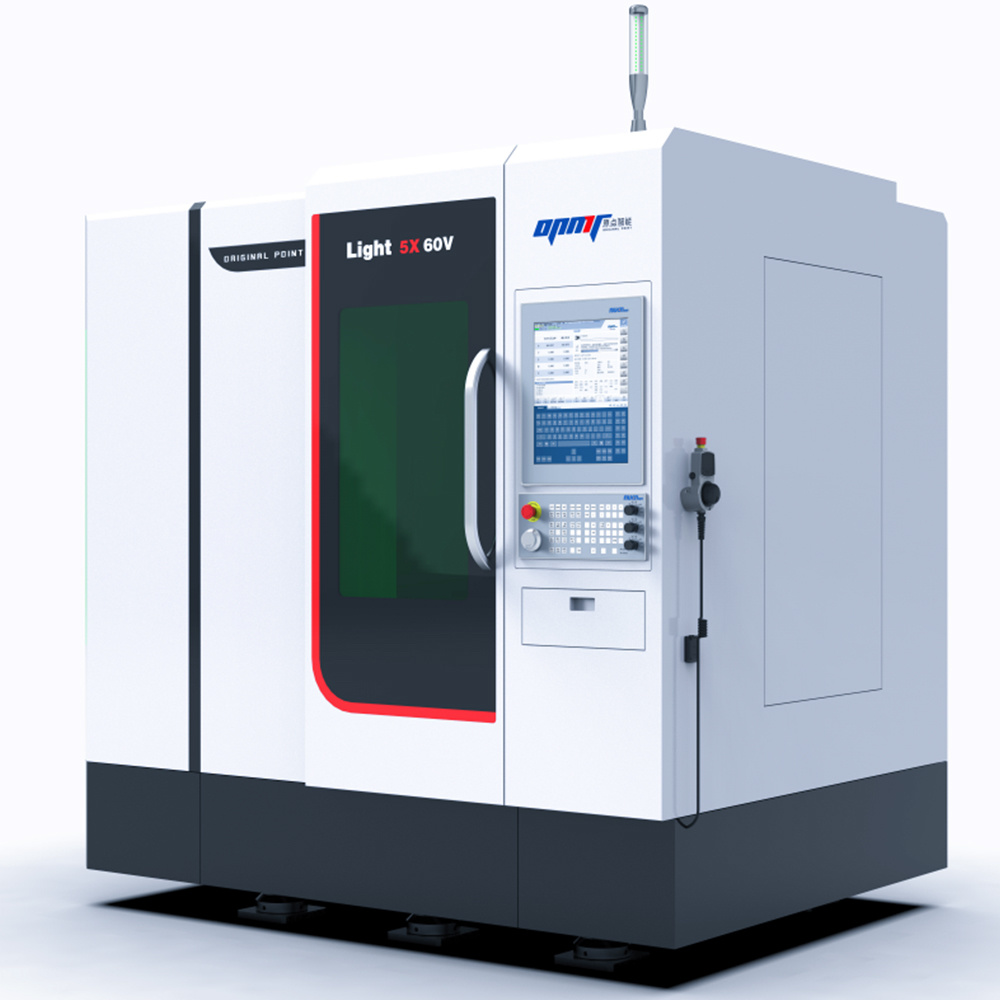

Light 5X 60V

Meanwhile, OPMT demonstrated the Light 5X 60V vertical laser five-axis linkage machining center. This equipment can achieve high-precision processing of complex contours on large curvature surfaces, bringing more possibilities to industrial manufacturing. Its appearance once again proves OPMT’s leading strength in the field of laser technology.

As a rapidly developing high-tech enterprise, OPMT has always adhered to being driven by technological innovation, and set a new benchmark for the development of domestic laser manufacturing equipment.

At this CCMT2024, OPMT not only demonstrated the technical strength of laser manufacturing, but also the firm determination to lead a new era of intelligent manufacturing in all-laser parts manufacturing. During the new technological revolution, OPMT will lead by example and target the "laser knife" in key national industrial fields such as aerospace, automotive, ocean operation equipment, and CVD diamonds, integrating AI technology to create a new generation of CNC. The system relies on multi-field technologies such as intelligent control technology, intelligent sensing technology, intelligent decision-making technology, and intelligent learning technology to accelerate the launch of AI laser CNC machine tools, continuously promote technological innovation for upgrading to Industry 4.0.

Related News

Why non-standard cutting tool is very important

Apr 24,2024

Modern development trend grinding north carolina

Apr 24,2024