Welcome to Original Point Intelligent Technology

Apr 24,2024

What is the picking operation for manufacturing aluminum alloy sample?

As per the function and strength of parts, models can be made of different materials.

Of the many metal materials, aluminum is the first option for many engineers owing to its excellent appearance, excellent performance and reasonable prices.

Can say that, as long as the aluminum alloy can meet the performance needs, most will opt for aluminum alloys.

At present, you can select the use of cnc manufacturing and machinery manufacturing, 3d printing or aluminum casting service to make an aluminum sample based on the number and shape of parts prices.

All of this method has its benefits and defects. Mischeck can lead to high manufacturing cost.

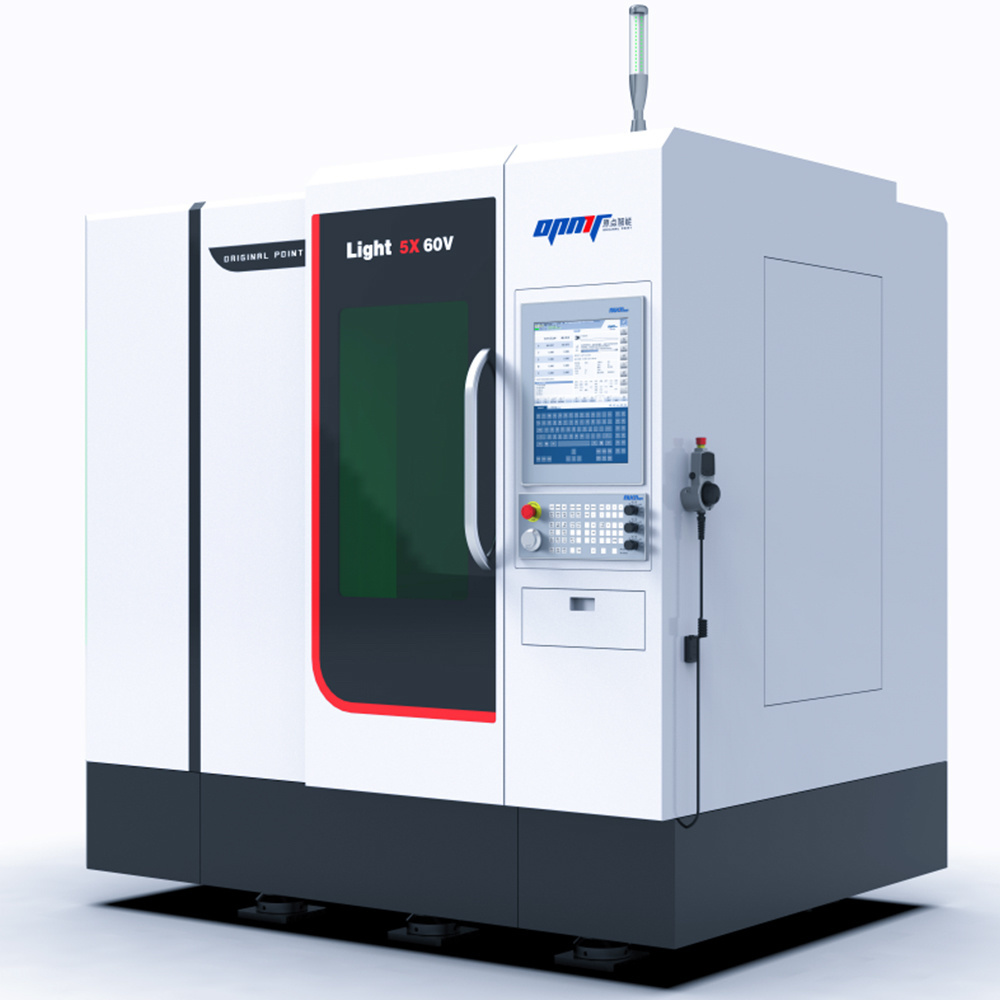

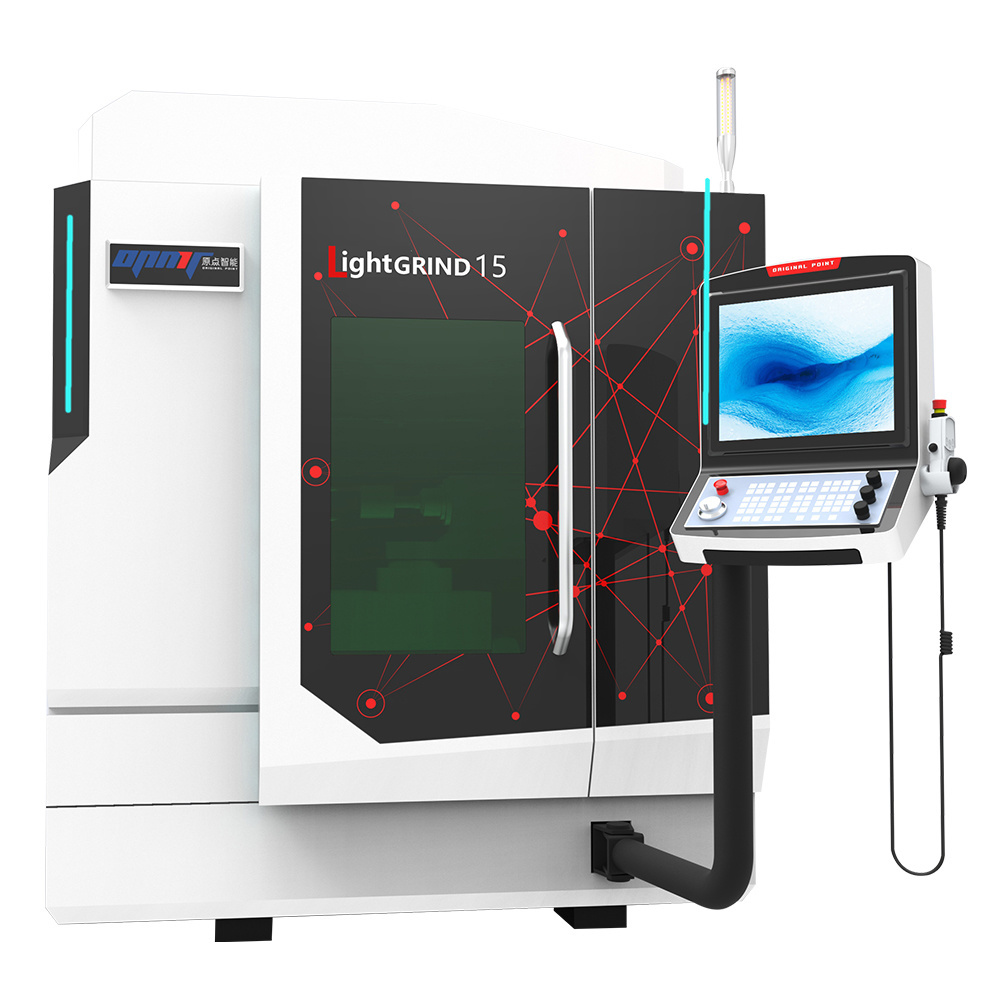

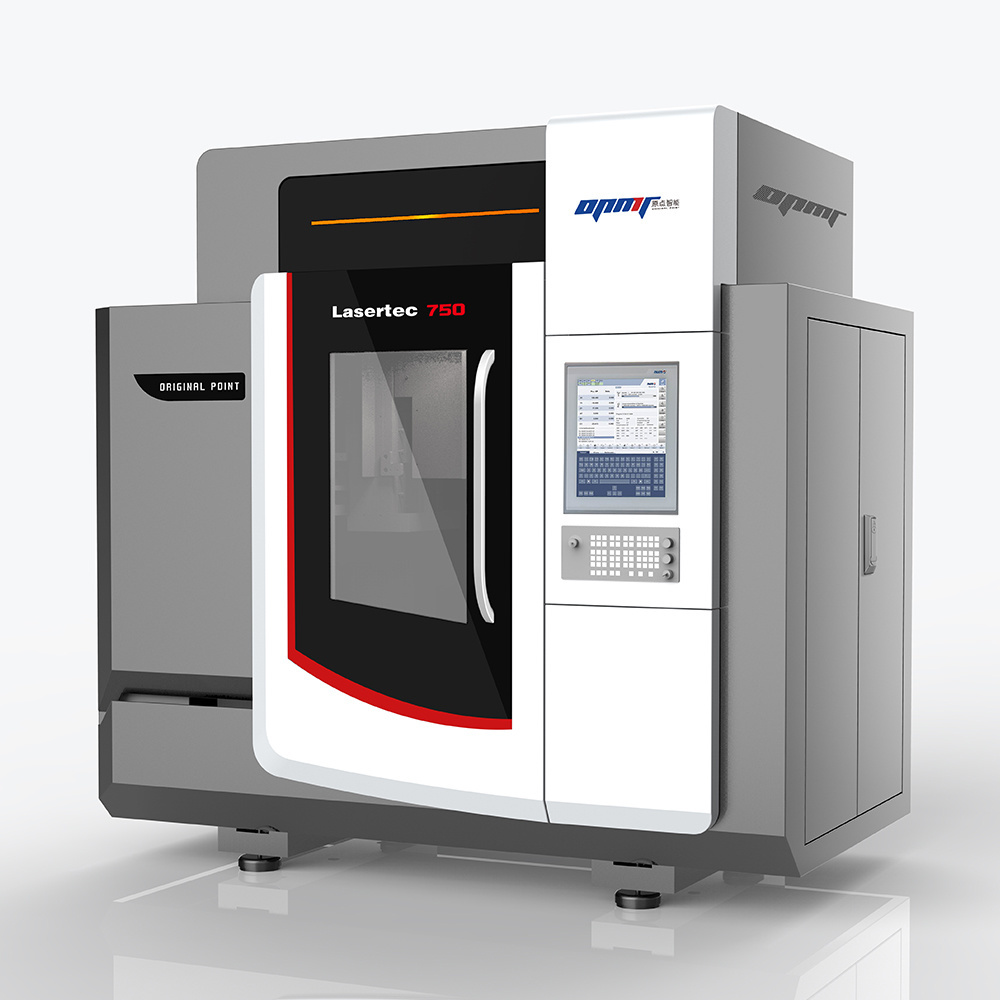

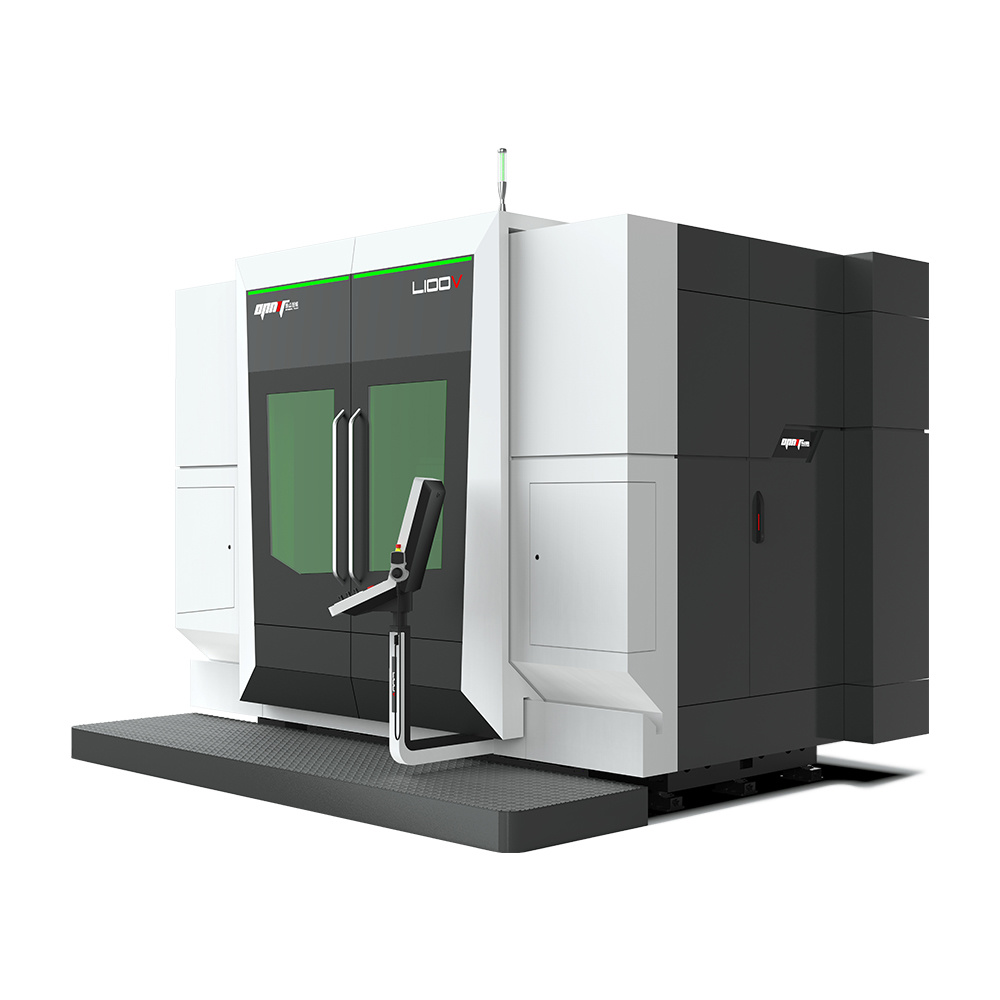

01. Cnc manufacturing and machinery manufacturing

Cnc manufacturing and machinery manufacturing is one of the most common ways in aluminum manufacturing. The operation is made by meticulous control of the device tool to remove the aluminum part of the work and let go of the part you want.

As the material cutting method of manufacturing, it waste materials. But what makes the cnc manufacturing operation different?

Cnc manufacturing and machinery manufacturing can provide high quality, excellent surface finish, frequency, and a wide range of compatible aluminum alloys.

Cnc manufacturing and machinery manufacturing are special occasion for manufacturing models. 4. Axis and 5-axis cnc milling machine allows you to create complex models of other processing techniques that are hard to handle.

3d printing

3d printing is the use of material manufacturing technology to make samples of aluminum, can reduce material waste. Metal sintering direct laser (dmls) technology can be used to generate 3D printing aluminum samples. There is a layer after layer aluminum powder with high-power laser shaped like the required shape.

Similar to cnc manufacturing, 3D printing is based on a canadian 3D model for the creation of an accurate aluminum model, which can make a complex engineering with a cross-door interior. However, 3D printing of aluminum samples is not cheap, and it usually needs more surface treatment.

3d printing of aluminum sample is always more expensive than cnc manufacturing and machinery manufacturing. So, 3D printing is an occasion for the manufacture of small parts, in particular test version and products handboard.

03. Investment casting

Investment casting, which has a date of several years, is a casting operation used in the manufacture of aluminum model. Here, aluminum parts are made of aluminum melt casting in molds made of wax models.

Owing to the need for special equipment, the production cost of molds is very high. So, making one or two models mold is not economic and is not occasion for mass production.

Die-casting offers excellent surface finish, very durable dimensions, compatible with a wide range of aluminum alloys. In addition, casting is less material waste than cnc manufacturing and machinery manufacturing.

The only fault of the operation is the size of the restrictions. This may not be the best option if you are making large, huge aluminum parts.

Related News

Why non-standard cutting tool is very important

Apr 24,2024

Modern development trend grinding north carolina

Apr 24,2024