Welcome to Original Point Intelligent Technology

Apr 24,2024

Several popular ways of processing the theme

Hand in hand with the fast development of industrial production, thread, as a key factor of communication and transmission elements, are used very wide in various machines and equipment. But the processing of the theme is also a work of art. In this paper, we will show a couple of popular ways of processing the thread.

Tapping is the most common method in processing the thread, mainly by making use of wall hole cutting thread. Tapping needs to use tools like taps and drilling.

First, drill holes in the work with the right specifications, and then insert the tap into the hole, cutting the thread by rotating the tap or the starter. Utility model has high precision and efficiency of tapping on the screw, which is occasion for processing screw threads of different materials and specifications.

Second theme

The theme is mainly through lathe, is high efficiency and high precision thread processing method. Before turning the thread, you need to install cutting tools and the work and adjust the lathe of the parameters.

Then, the thread is cut off rotating with a tool or work piece. Auto screw thread can be processing with different specifications and materials, high precision and efficiency.

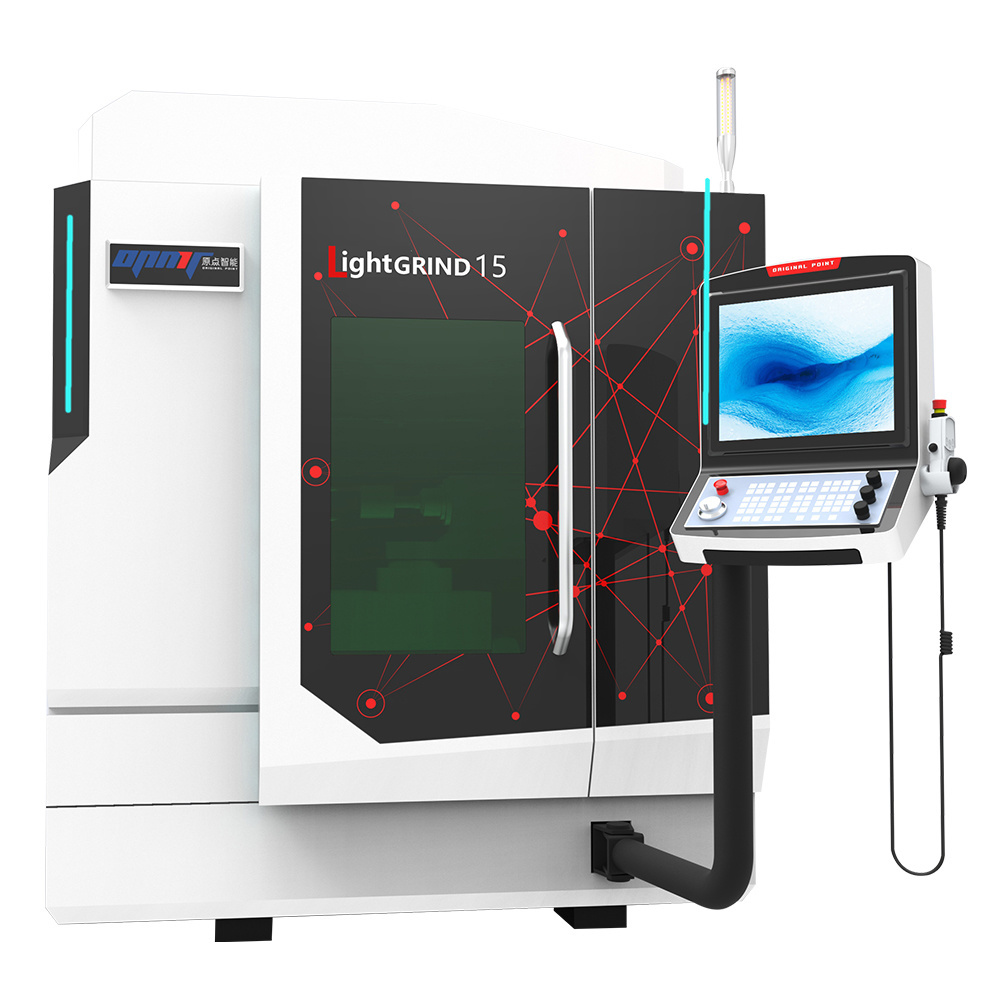

Twister grinding

Spiral grinding is a special type of thread processing method, in which the thread can be cut by the relative motion between grinding the pieces of the film.

The benefit of the model has the benefits of high precision screw thread can be processing, and the cutting speed is faster, and the utility model is occasion for mass production. Even so, the cost of grinding the twister required the use of special mills and fittings.

Rolling thread

Rolling thread is a fairly new method of processing the thread that presses the surface of the work by rolling the rolling wheel in the form of a thread. The benefit of a model with the benefits of this rolling thread can be processing with high precision, low surface sealing, binding, and wear resistance of the connection can be improved. However, you need to use special rolling threads and dance, and the cost is even louder.

This is several ways of processing the joint thread, each of which has its own characteristics and scope of application. In the physical production, it is essential to select the right processing method in line with the set conditions to ensure the quality and efficiency of processing of the thread. At the same time, you also need to pay attention to the safety of operation and maintenance of equipment, to ensure the smooth production.

Related News

Why non-standard cutting tool is very important

Apr 24,2024

Modern development trend grinding north carolina

Apr 24,2024