Welcome to Original Point Intelligent Technology

Apr 24,2024

Aluminum alloy polishing mirror

In the modern manufacturing industry, surface treatment is one of the key steps in order to provide beauty products and texture. Aluminum alloys are used wide in the field of aviation, cars, electronics and so on, for their excellent characteristics like light weight, high strength, wear resistance and so on. In order to increase the improvement of the appearance and quality of aluminum alloy products, mirror polished technology in the manufacture of aluminum alloy has become the focus of manufacturers.

01. The value of aluminum alloy surface treatment

Aluminum alloy can be affected by the stamping, casting, or cutting operation. This surface defects not only impact the appearance of the product, but can also reduce the wear resistance and mechanical clearance.

So, by surface treatment, the surface of aluminum alloy is more smooth, smooth, not only beautiful, but also help to improve wear resistance and wear resistance.

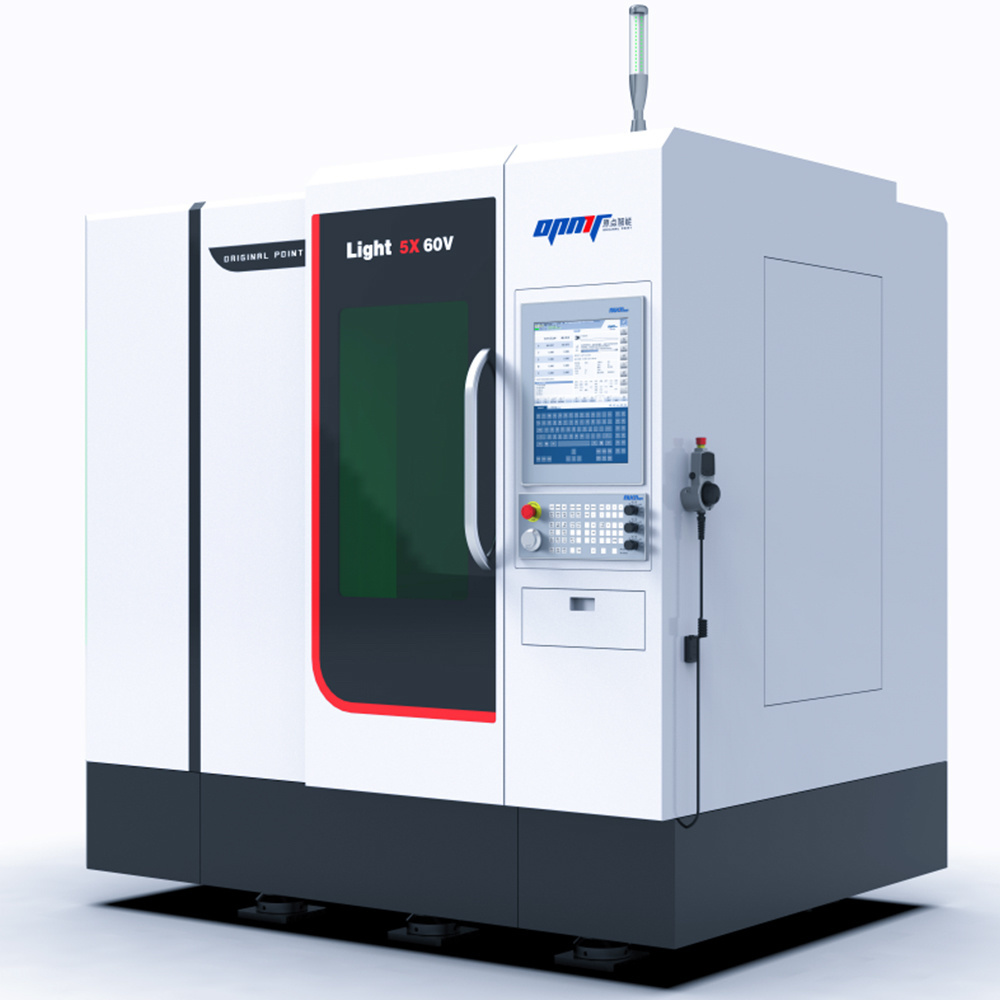

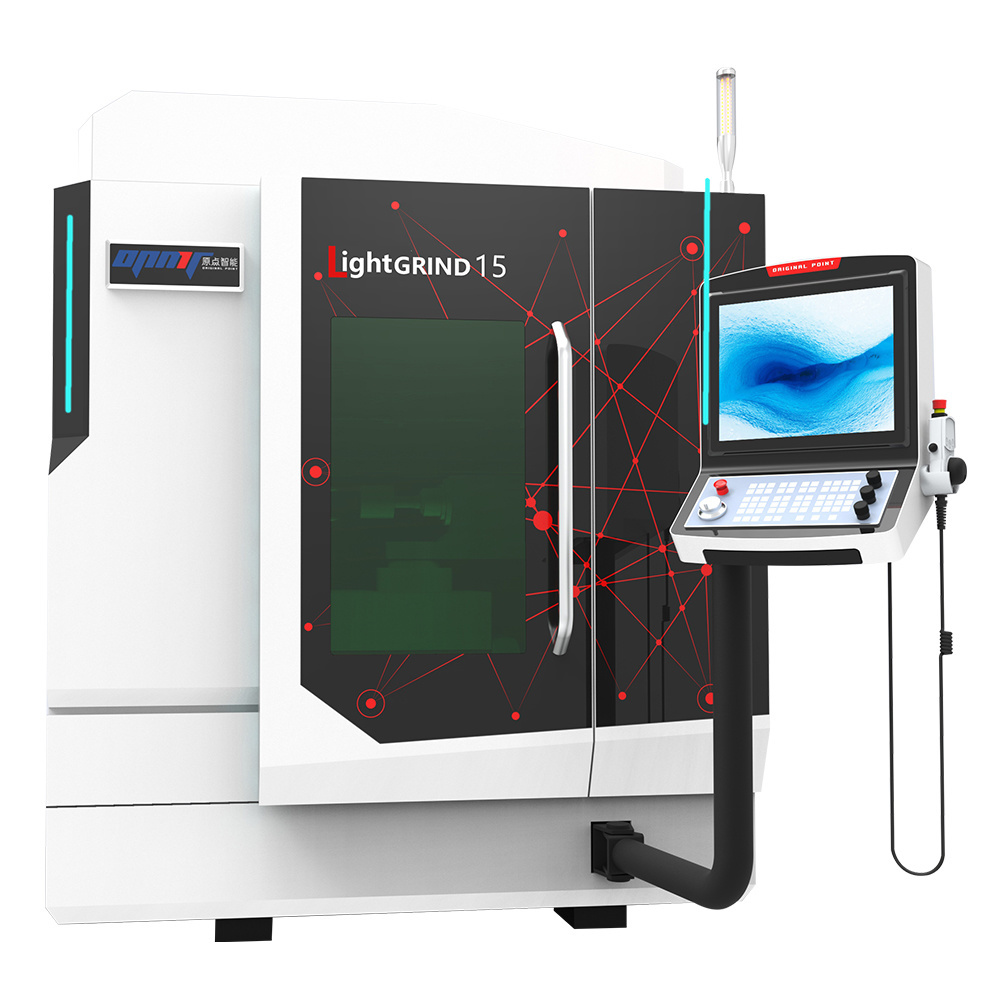

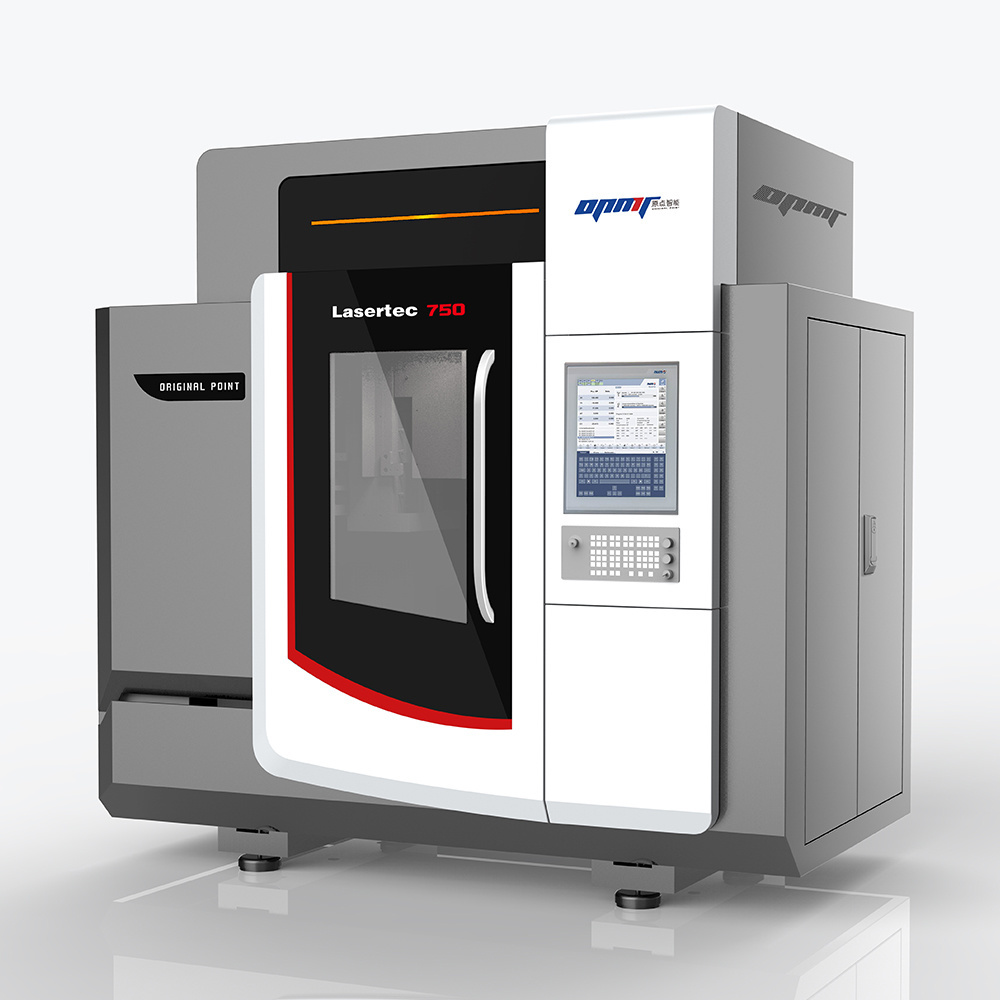

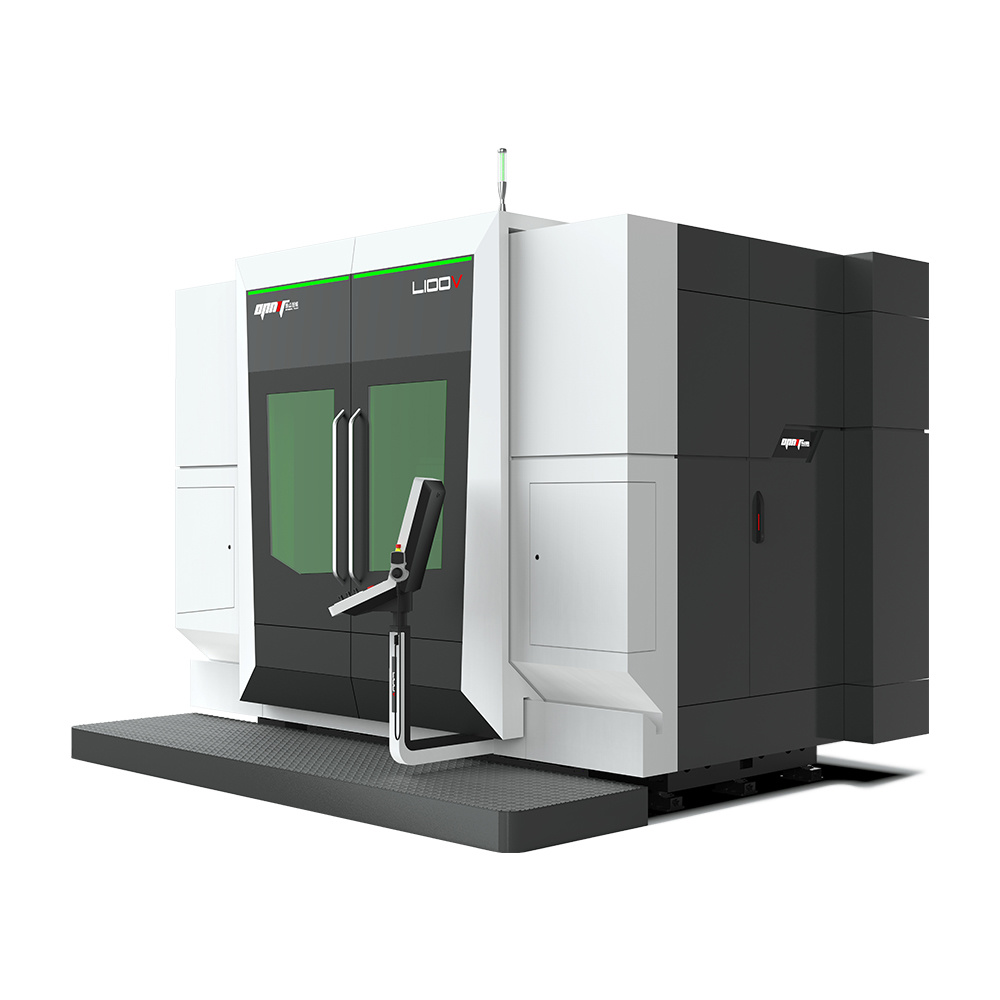

Aluminum alloy polishing machine

Polishing is a kind of surface treatment method that can improve the surface finish by friction and friction particles. In aluminum alloys, polishing not only cleats surface defects, but also creates a mirror surface like glitter.

Aluminum alloy polishing usually covers the following steps:

A. Pretreatment

Before polishing, the right processing needs to be made on the surface of aluminum alloys. This can cover the removal of the oxide layer, cleaning the greases and impurities to ensure the effective treatment of surface defects in the polishing operation.

Raw grinding

Coarse grinding is the first step in polishing, removing the surface rough and defects with the largest abrasive. The move is designed to polish the surface fast and to provide the condition for the polishing.

C polishing

The polishing phase is to polishing the surface of aluminum alloys gradually, making it more smooth. Very often, with a reduction in the size of abrasive particles, the surface glitter is gradually increasing by mechanical or chemical polishing.

D. End treatment

After polishing up to a certain stage, the treatment can be made, so as to use fine abrasive or polishing paste to increase the surface brightness and finish.

Polished aluminum alloy application

The polished surface of aluminum alloy is always a mirror like light, making it used wide in several fields:

A. Auto parts

In the automotive industry, polished aluminum alloy is used in the manufacture of trim body parts, wheel hub, etc. High-quality and beautiful exterior finish for cars offers a unique attraction.

B. Household items

Polished aluminum alloy is common in household materials, like kitchen tools, frame furniture, and so on. This products is not only noble appearance, but also easy cleaning and maintenance.

C. Air space field

In the field of aviation and space, polished aluminum alloys used in the aircraft shell industry, interior decoration, and so on, in order to improve the appearance of aircraft and reduce overall weight.

Electronic products

Polished aluminum alloy used in electronic products, like laptop, smartphone frame. Bright appearance, add to the fashion sense of products.

4. Precautions

When polishing aluminum alloys, pay attention to the:

A. Material picking

Different types of aluminum alloys have the capacity to adjust to different polishing, so we need to know the material specifications before polishing.

Control of the operation

The control precision of the operation, including the picking of abrasive, pressure and speed required to ensure the finishing of the glitter.

C. Security protection

Polishing involves the use of dust and chemicals, and the operators need to wear the right protective equipment to ensure the safety of production.

Through the aluminum alloy surface mirror polishing operation, not only improve the appearance of the quality of aluminum alloy product, but also expand the field of application. The application of this operation can provide more innovation and the possibility of team up between manufacturers, and at the same time, it can be met by the request of users for high quality products. In the future, with the development of surface treatment technology, aluminum alloy mirror polishing technology is expected to show unique charm in more fields.

Related News

Why non-standard cutting tool is very important

Apr 24,2024

Modern development trend grinding north carolina

Apr 24,2024